Crystallization method of cephalosporanic acid

A cephalosporanic acid and crystallization technology, which is applied in the field of preparation of pharmaceutical and chemical raw materials, can solve the problems affecting the quality and poor quality of the final synthetic product, and achieve the effect of strong applicability and good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

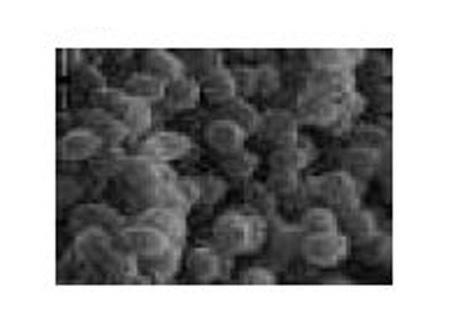

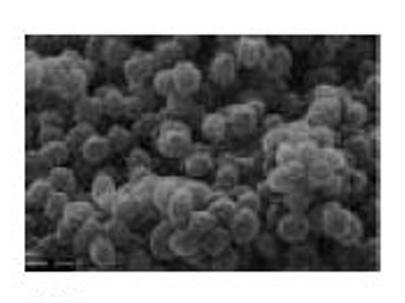

Image

Examples

Embodiment 1

[0014] Measure 1000ml of cephalosporanic acid liquid to be crystallized, with a concentration of 15-25mg / ml. At 20-30°C, add 1 g of sodium bisulfite, stir for 30 minutes, and add 5 ml of triethylenetetramine. Stir, add hydrochloric acid with a mass ratio concentration of 15% to pH 6.2-6.3, and continue stirring until crystals appear. After growing the crystal for 30 minutes, continue to add hydrochloric acid with a mass ratio concentration of 15%, until the pH of the liquid to be crystallized is 4.2-4.4. Cultivate the crystal for 30 minutes, cool down to 0-5°C, and vacuum filter. Wash twice with 100ml of water at 0-1°C, and then wash with 150ml of acetone at 0-1°C for three times. The material is discharged and dried in a vacuum drying oven at 38-40°C for 3-5 hours under the pressure of -0.098Mpa.

Embodiment 2

[0016] Measure 1000ml of cephalosporanic acid liquid to be crystallized, with a concentration of 15-25mg / ml. Add 1ml of triethylenetetramine. Stir, and add hydrochloric acid with a mass ratio concentration of 18% until crystallization occurs. After growing the crystal for 30 minutes, continue to add hydrochloric acid with a mass ratio concentration of 18%, until the pH of the liquid to be crystallized is 4.2-4.4. Cultivate the crystal for 30 minutes, cool down to 0-5°C, and vacuum filter. Wash twice with water and three times with acetone. The material was discharged and dried in vacuum.

Embodiment 3

[0018] Measure 1000ml of cephalosporanic acid liquid to be crystallized, add 2g of sodium bisulfite at room temperature, stir for 20 minutes, and add 3ml of triethylenetetramine. Stir, add hydrochloric acid with a mass ratio concentration of 12% to pH 6.2-6.3, and continue stirring until crystals appear. After growing the crystal for 60 minutes, add hydrochloric acid with a mass ratio concentration of 15%, until the pH of the liquid to be crystallized is 4.2-4.4. Crystal growth for 20 minutes, cooling to 0-5°C, vacuum filtration, washing the filtered crystal twice with cold water and twice with acetone. The material is discharged and dried in a vacuum oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com