Preparation process for anti-oxidation copper-based bonding wires

A preparation process and bonding wire technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of bonding wire packaging, high bonding wire hardness, etc. Destruction, reduction of bonding energy, effect of high bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

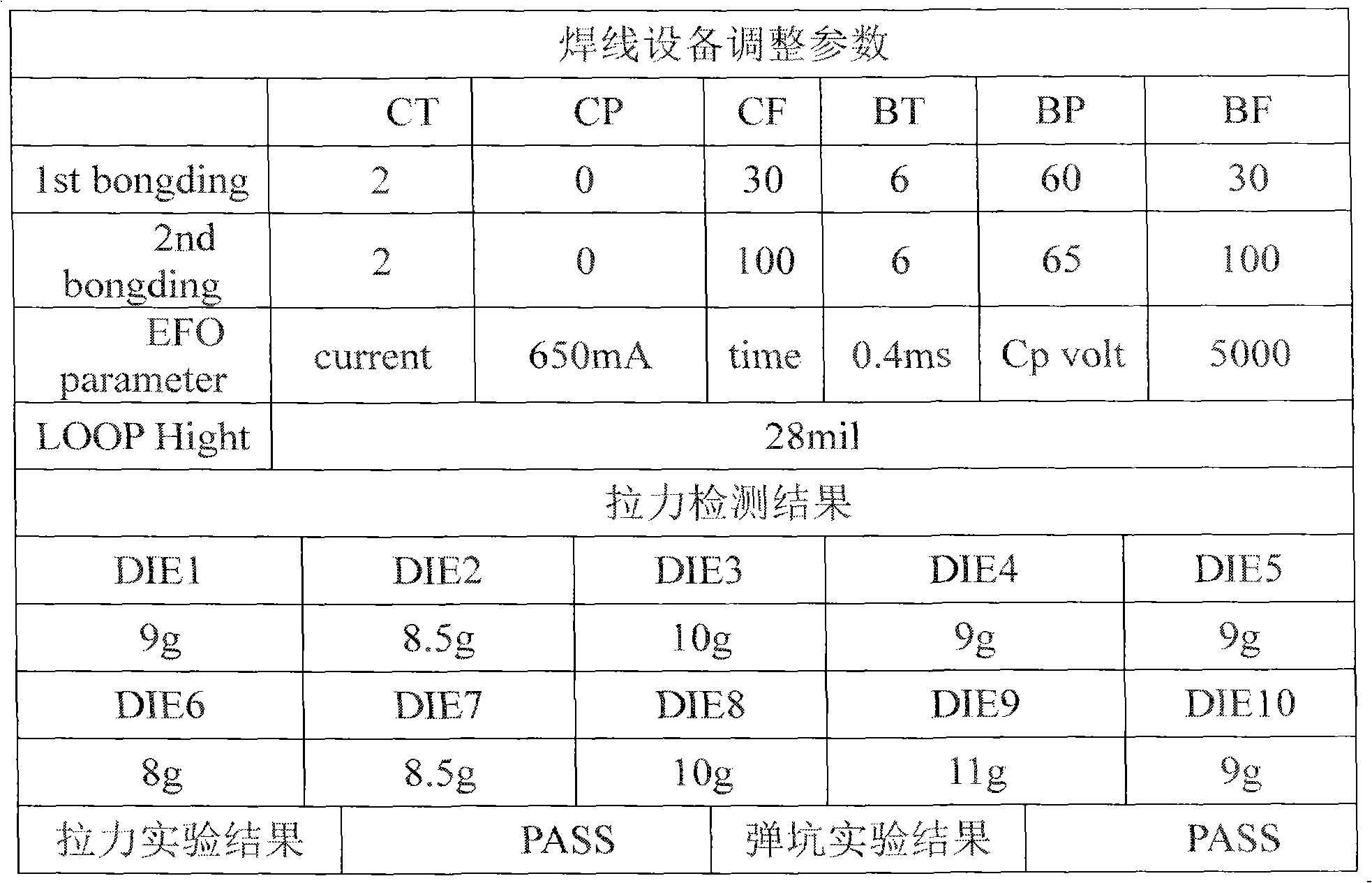

Image

Examples

Embodiment 1

[0028] A copper-based bonding wire, the basic material is copper, and trace metal elements such as Pt, Ce, and Pd are added to form a master alloy base material, and the surface of the metal wire made of the master alloy base material is plated with a layer of gold. Among them, the purity of copper and gold plating is higher than 99.99%.

[0029] The mass proportion of each metal component in the bonding wire material is respectively: Cu is 94.9933%, trace metal element Pt is 0.0007%, Ce is 0.002%, Pd is 0.004%, gold plating is 5%, and the diameter of the bonding wire is 50 microns , the thickness of the gold layer is 0.6 microns.

[0030] The preparation of copper-based bonding wire comprises the following steps:

[0031] Step one, mixing metal substrates. Cu with a purity higher than 99.99%, plus selected trace metal materials Pt, Ce, and Pd, is mixed as a master alloy base material, and the preliminary preparation for mixing and smelting is done.

[0032] Step 2, melting...

Embodiment 2

[0040]A copper-based bonding wire, the basic material is copper, and trace metal elements such as Pt, Ce, and Pd are added to form a master alloy base material, and the surface of the metal wire made of the master alloy base material is plated with a layer of gold. Among them, the purity of copper and gold plating is higher than 99.99%.

[0041] The mass proportion of each metal component in the bonding wire material is respectively: Cu is 95.9923%, the trace metal element Pt is 0.0007%, Ce is 0.004%, Pd is 0.003%, gold-plated gold is 4%, and the diameter of the bonding wire is 50 Micron, the thickness of the gold layer is 0.5 micron.

[0042] The preparation technology of described copper-based bonding wire comprises the following steps:

[0043] Step one, mixing metal substrates. Cu with a purity higher than 99.99%, plus selected trace metal materials Pt, Ce, and Pd, is mixed as a master alloy base material, and the preliminary preparation for mixing and smelting is done. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com