Micro-energy system with high weight ratio energy density and method and application thereof

A technology of energy density and weight ratio, applied in the field of microelectronics, can solve problems such as low energy density, save space, improve volume specific energy density, and facilitate monolithic integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

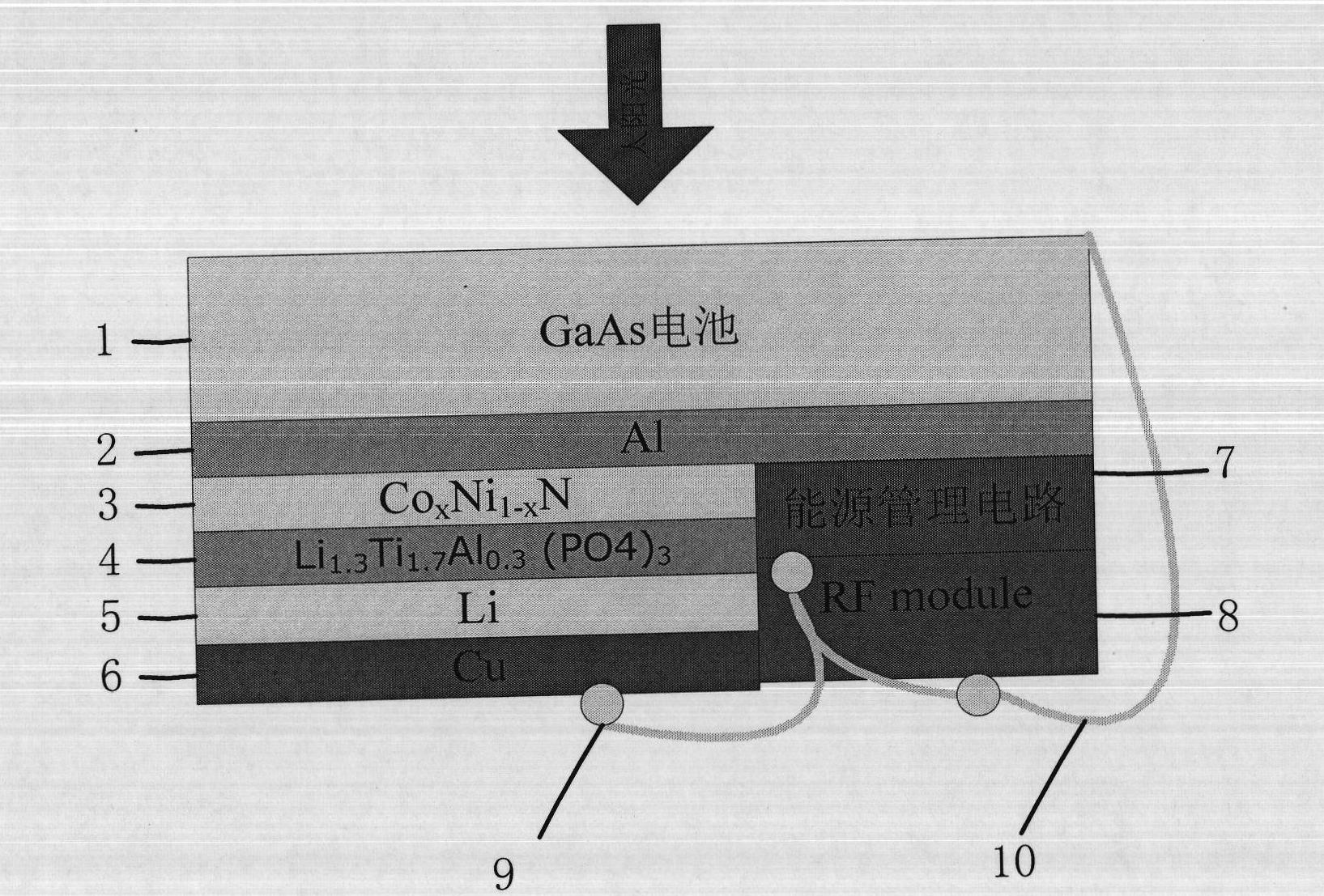

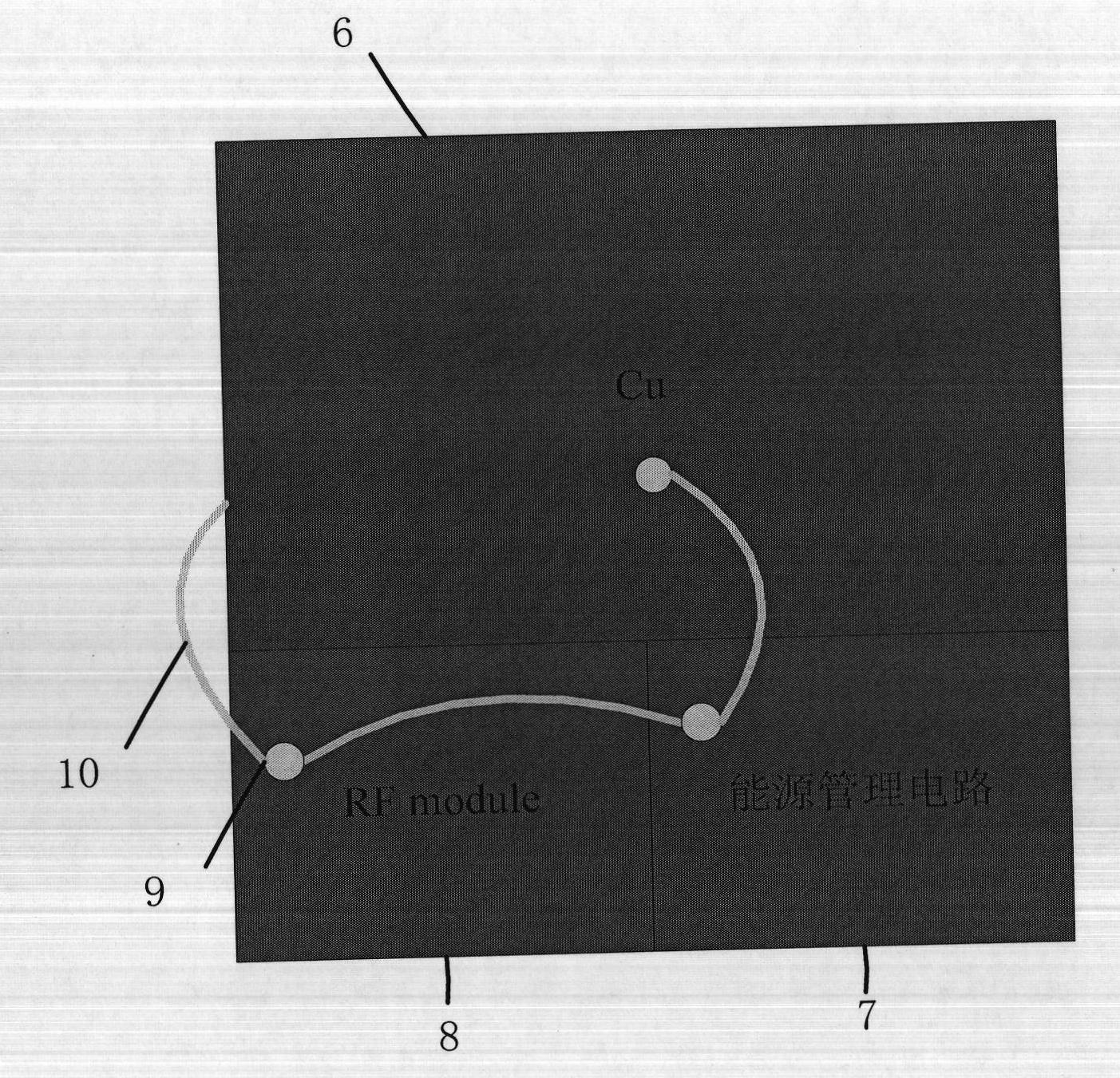

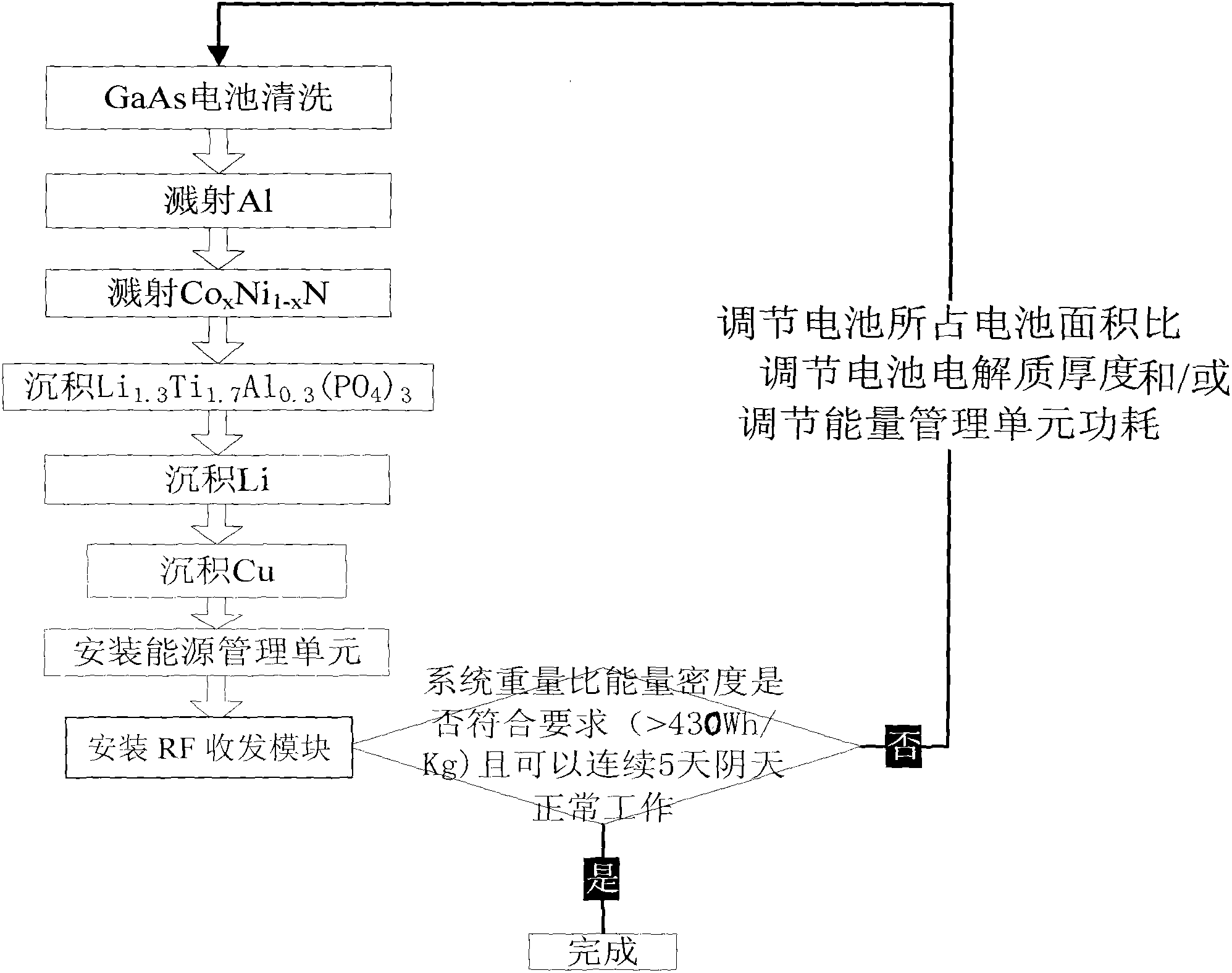

[0027] The present invention is a manufacturing process of a high-weight specific energy density micro-energy system (such as figure 2 )as follows:

[0028] ① Clean the back surface of the GaAs solar cell, the cleaning condition is to use isopropanol, megasonic cleaning, room temperature, 3min;

[0029] ②Grow 150-350nm Al film by sputtering; the sputtering conditions are: the distance between the Al target (5N) and the substrate is 4.5cm, and the background pressure is 2×10 -4 Pa, the target should be sputtered for 30min before depositing the film, the sputtering power is 90W, the sputtering atmosphere is Ar, the flow rate is 30sccm, the working pressure is 1.2Pa, the deposition power is 110W, the substrate temperature is less than 90°C during deposition, The rate is 25nm / min, and the continuous deposition time can be adjusted to obtain an Al film with a thickness of about 150-350nm;

[0030] ③Co x Ni 1-x N thin film: Sputtering uses a metal nickel-cobalt alloy with a diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com