High-power semiconductor laser light source system for laser processing

A laser light source and laser processing technology, applied in semiconductor laser devices, laser devices, laser welding equipment, etc., can solve the problems of low photoelectric conversion rate, short life, high cost, and achieve low system cost, long life, and large working distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

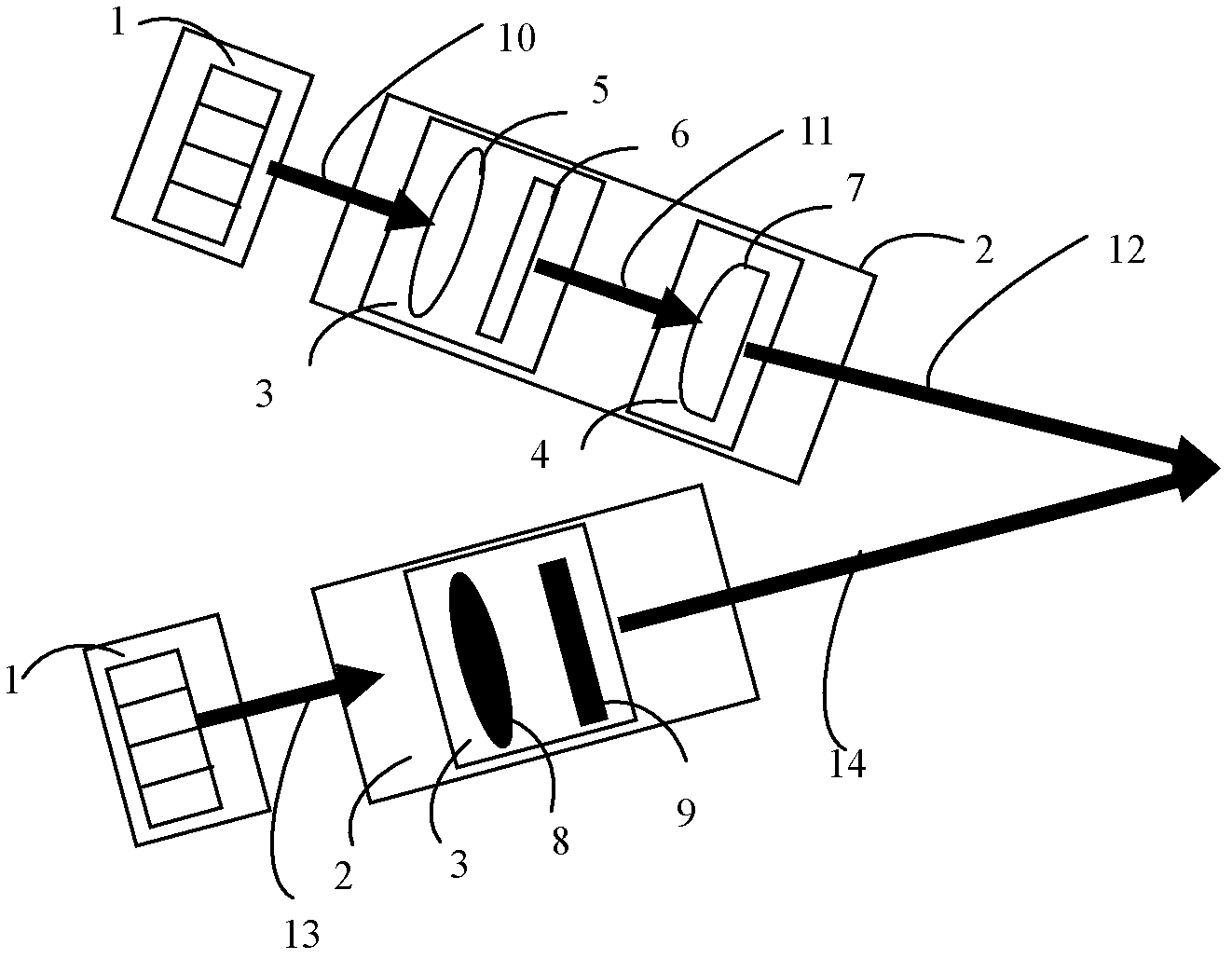

[0034] Such as figure 1 As shown, the basic structure adopted in this embodiment is the same as the structure explained above, including two semiconductor laser stacks 1 and shaping lens groups 2, and the two semiconductor laser stacks 1 and the shaping lens groups 2 at the rear end form an angle α is placed and arranged in a fan shape so that the shaped beams are superimposed and output.

[0035] For the first semiconductor laser stack 1, it is composed of 40 bar chips with microlenses. After the semiconductor laser stack 1, a shaping lens group 2 is set. The shaping lens group 2 includes a fast axis shaping lens group 3 and Slow axis shaping lens group 4 , fast axis shaping lens group 3 includes two spherical lenses 5 and 6 , slow axis shaping lens group 4 includes aspheric lens 7 .

[0036] For the second semiconductor laser stack 1, it is composed of 40 bar chips with microlenses. After the semiconductor laser stack 1, a shaping lens group 2 is arranged. The shaping lens ...

Embodiment 2

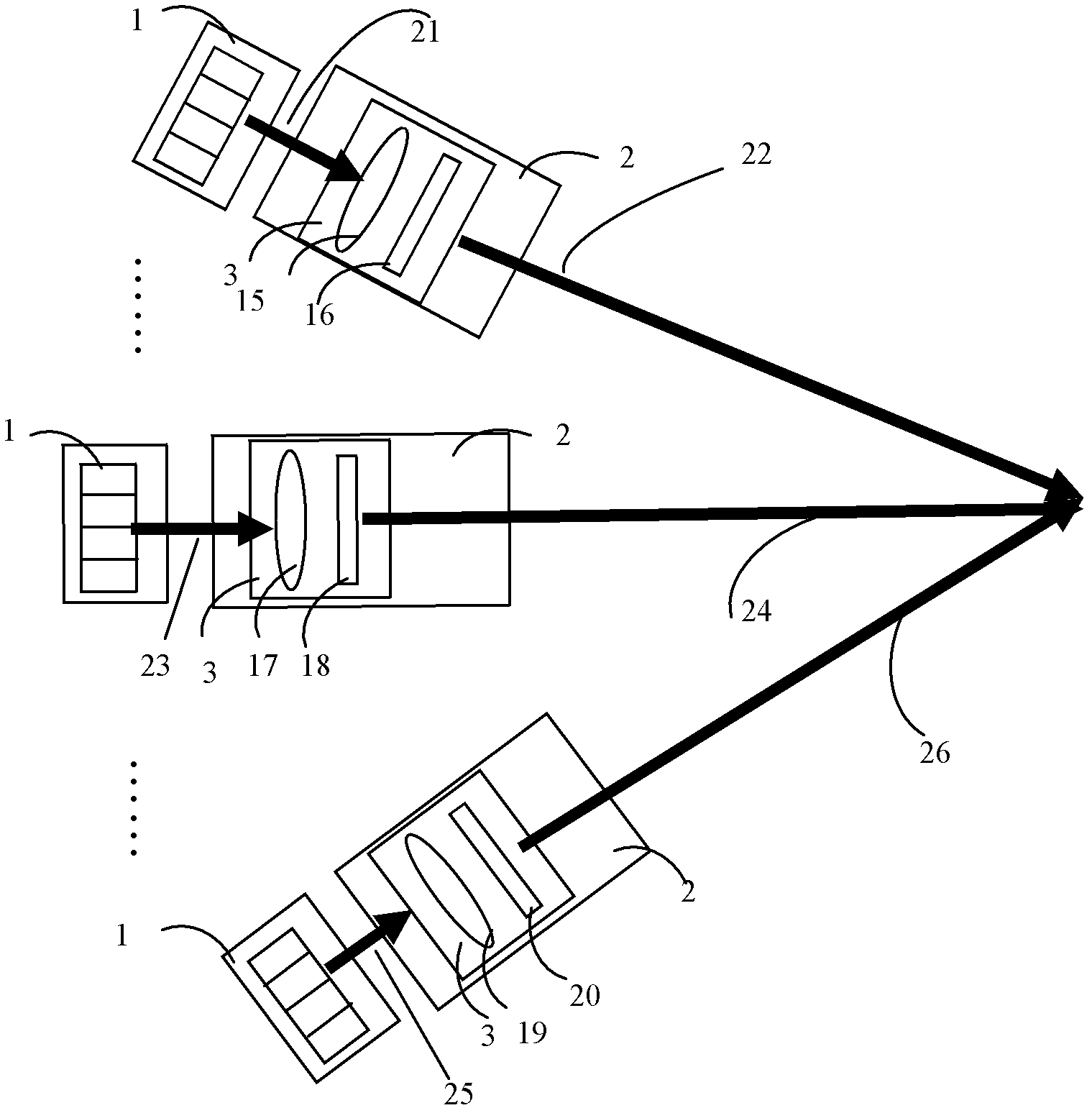

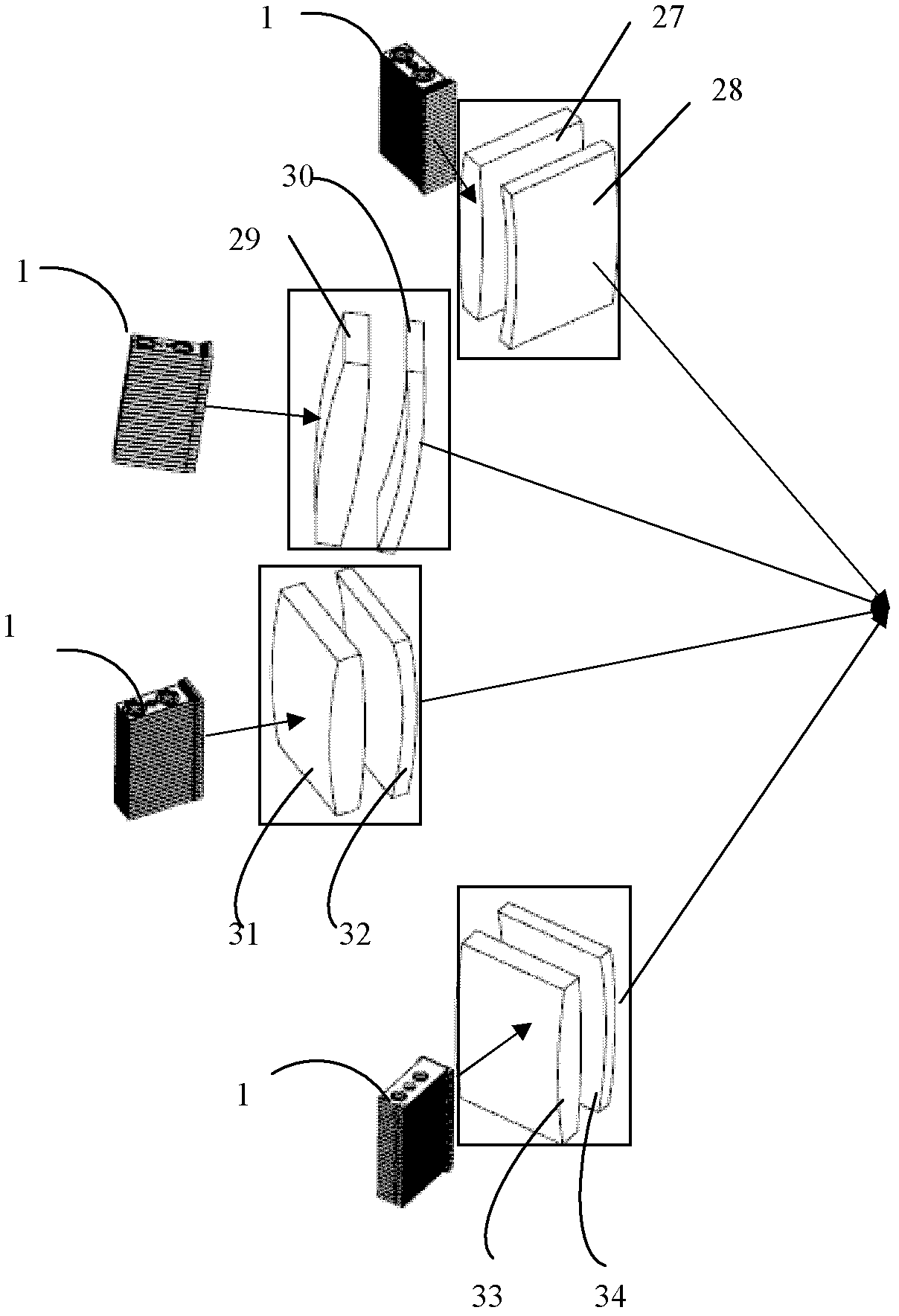

[0039] Such as image 3 As shown, it includes four semiconductor laser stacks 1 and a shaping lens group 2, and the four semiconductor laser stacks 1 are arranged in a fan shape, a cone shape, or a hemispherical shape.

[0040] For the first semiconductor laser stack 1, it is composed of 50 bar chips with micro-lenses added. After the semiconductor laser stack 1, a shaping lens group 2 is set. The shaping lens group 2 includes two fast-axis collimating spherical surfaces. Lenses 27 and 28.

[0041] For the second semiconductor laser stack 1, it consists of 50 bar chips with micro-lenses superimposed. After the semiconductor laser stack 1, a shaping lens group 2 is set. The shaping lens group 2 includes two fast-axis collimating spherical lenses. 29 and 30.

[0042] For the third semiconductor laser stack 1, it is composed of 50 bar chips with micro-lenses added. After the semiconductor laser stack 1, a shaping lens group 2 is set, and the shaping lens group 2 has two fast-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com