Method for producing oyster hydrolyzate through microbial fermentation

A technology for microbial fermentation and oysters, which is applied in the fields of aquatic product processing and microbial biology, can solve the problems of increased production cost and high price of finished protease, and achieves the effects of low cost, reasonable design of process parameters and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

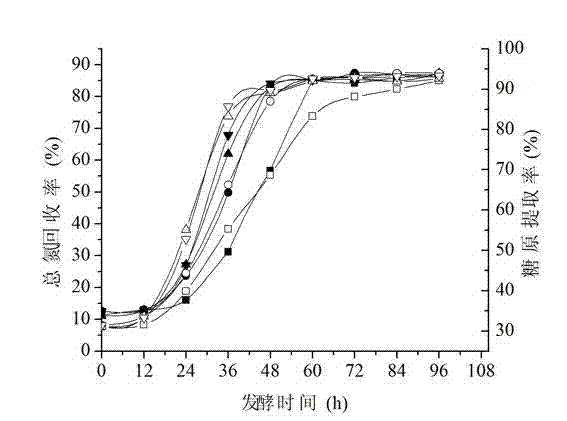

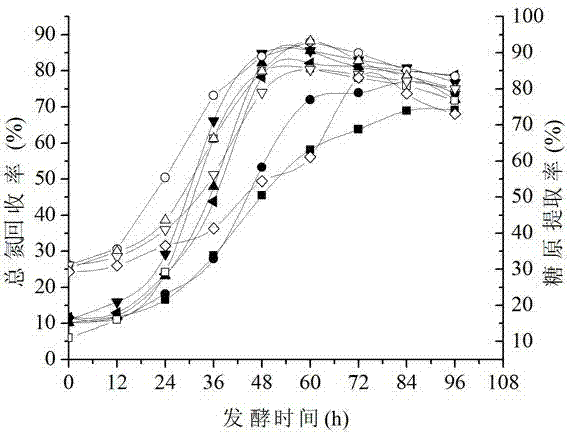

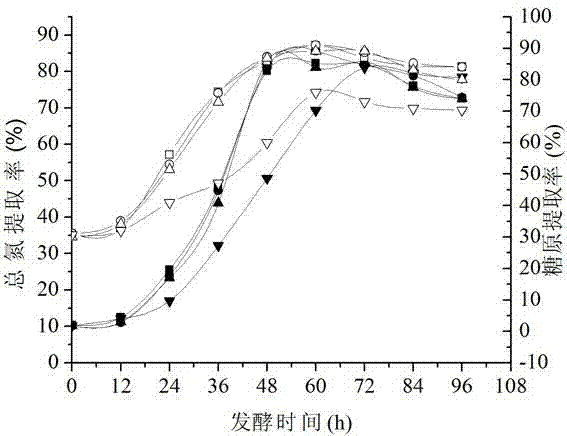

[0038] Embodiment 1, a kind of microbial fermentation prepares the method for oyster hydrolyzate, it adopts Aspergillus oryzae liquid fermentation method, and its specific steps are as follows:

[0039] (1) Preparation of oysters: buy fresh Pacific oysters, clean them up, take out the oyster meat, and homogenize with a homogenizer;

[0040] (2) Preparation of fermentation substrate: the homogenate was diluted with distilled water until the M / V of the protein concentration was 15%, the pH value was adjusted to 7.0 with 1M NaOH, and pasteurized at 60°C for 30 minutes to obtain the fermentation substrate;

[0041] (3) Microbial fermentation: Activate the Aspergillus oryzae strain on the PDA slant medium, pick spores from the activated strain preservation slant and inoculate it into the PDA liquid medium, and cultivate it at 30°C and 120rpm until the cell concentration reaches 107CFU / ml, to obtain the fermented strain seed liquid; press the V / V 5% inoculation amount to inoculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com