Cr-free high boron iron-based wear-resisting dual-liquid dual-metal compound hammerhead and manufacturing method thereof

A composite hammer head and bimetallic technology, applied in grain processing, etc., can solve the problems of weak market competitiveness, high Cr content, high production cost, etc., and achieve the effects of easy promotion and application, increased service life, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

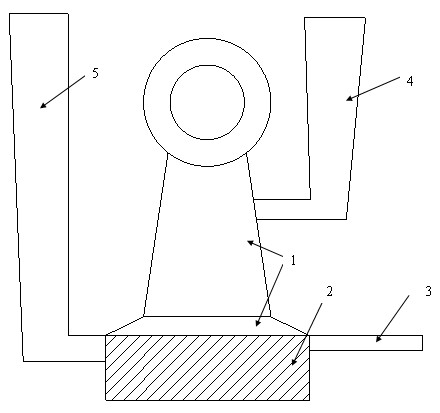

[0020] (1) Preparation of the hammer head wear-resistant layer: Put the scrap steel into an intermediate frequency induction furnace for smelting. After the molten steel is melted, add ferro-boron to continue smelting, and control the chemical composition of the molten steel to C 0.3%, B 4.5%, Si 0.4%, Mn 0.2 %, S 0.03%, P 0.01%, the rest is Fe (weight percentage); after re-dissolving, add 0.3% of the molten steel weight Al for deoxidation, slag off the furnace at 1600°C, and let stand and cool to 1480°C after leaving the furnace ; Pouring the sand mold through the runner 5, stop pouring after the molten steel flows out of the overflow port 3.

[0021] (2) Preparation of the toughness layer of the hammer handle: the scrap steel is used as a raw material to be smelted in an intermediate frequency furnace. The test found that the carbon content of the molten steel is 0.2%, and pig iron is added to adjust the carbon content to 0.3%. After the molten steel is melted, add 0.1% of the m...

Embodiment 2

[0023] (1) Preparation of the hammer head wear-resistant layer: Put the scrap steel into an intermediate frequency furnace for smelting. After the molten steel is melted, add ferroboron to continue smelting, and control the composition of the molten steel to C 0.7%, B 2.1%, Si 0.2%, Mn 0.4%, S 0.04%, the rest is Fe (weight percentage); after re-dissolving, add 0.2% Al of molten steel for deoxidation, slag off the furnace at 1573°C, and let it stand and cool to 1480°C after leaving the furnace; pouring through runner 5 In the sand mold, after the molten steel flows out of the overflow port 3, stop pouring.

[0024] (2) Preparation of the toughness layer of the hammer shank: use scrap steel as the raw material and put it into the melting furnace to smelt. The carbon content of the molten steel is determined to be 0.45%. After the molten steel is melted, 0.2% of the molten steel weight is added for deoxidation, and the slag is removed at 1565 ℃ out of the furnace; after the hammer h...

Embodiment 3

[0026] (1) Preparation of the hammer head wear-resistant layer: Put the scrap steel into an intermediate frequency induction furnace for smelting. After the molten steel is melted, add ferroboron to continue smelting, and control the chemical composition of the molten steel to C 1.0%, B 1.0%, Si 0.3%, Mn 0.3 %, P 0.02%, the rest is Fe (weight percentage); after re-dissolving, add 0.1% of the molten steel weight Al for deoxidation, slag off the furnace at 1600°C, and stand still to 1500°C after leaving the furnace; pouring through runner 5 In the sand mold, after the molten steel flows out of the overflow port 3, stop pouring.

[0027] (2) Preparation of the toughness layer of the hammer handle: use scrap steel as the raw material to put it in the melting furnace for smelting, check that the carbon content of the molten steel is 0.7%, add low-carbon steel to adjust the carbon content to 0.55%, and after the molten steel is melted, add the molten steel 0.3% Al is deoxidized, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com