Bending machine

A bending machine and bending die technology, applied in the field of bending machines, can solve problems such as inability to bend copper pipes in a curved shape, product quality cannot be guaranteed, and copper pipes cannot be bent, so as to reduce employee labor The effect of strength, improving machine utilization rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

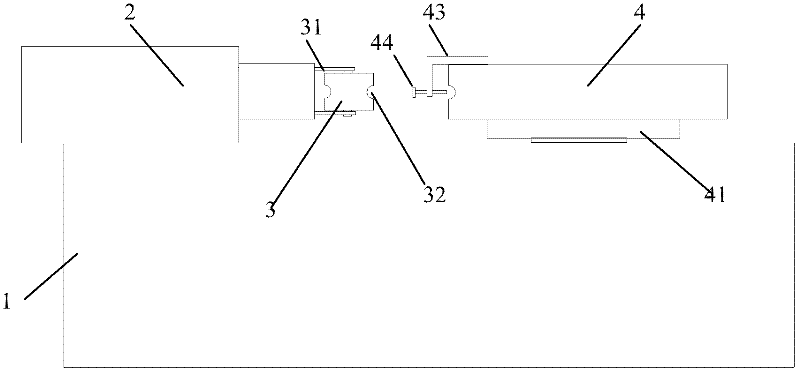

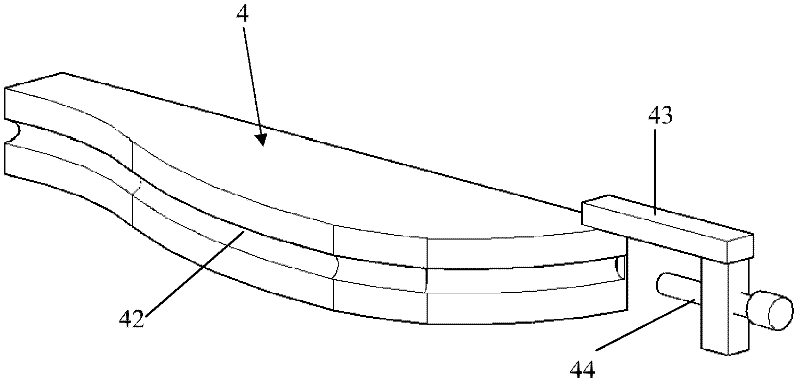

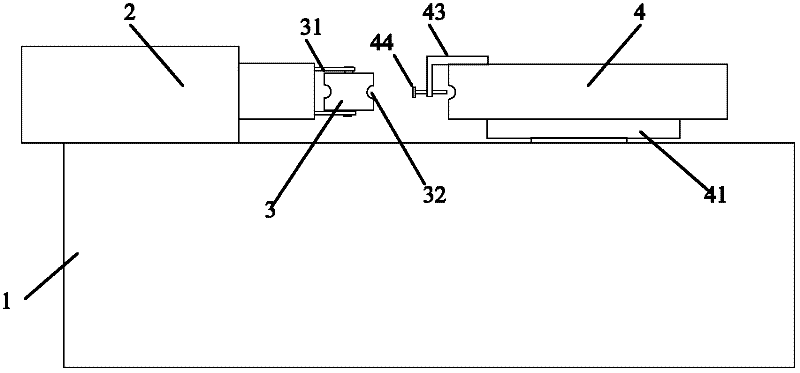

[0016] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 and figure 2 As shown, the bending machine of the preferred embodiment of the present invention includes a support box 1 fixedly arranged on the base, a push cylinder 2 fixedly arranged on one side of the upper surface of the box body, and rotatably fixed at the end of the piston arm of the cylinder 2 The bending wheel 3, and the bending module 4 that can be driven by the drive motor to rotate.

[0018] Wherein, the support box 1 is welded by hard metal plates, of course, the purpose of the present invention can also be achieved by welding pipes to form a support frame. Promoting cylinder 2 is fixedly arranged on one side of the upper surface of support case 1 by bolts, preferably, it is arranged on a corner of support case 1 and its piston arm points to the center of the upper surface of case body 1 . Fixed splints 31 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com