Production method for preparing isobutylene by adsorption separation

A technology for adsorption separation and isobutene, applied in adsorption purification/separation, etc., can solve the problems of high energy consumption, high reaction temperature, single product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

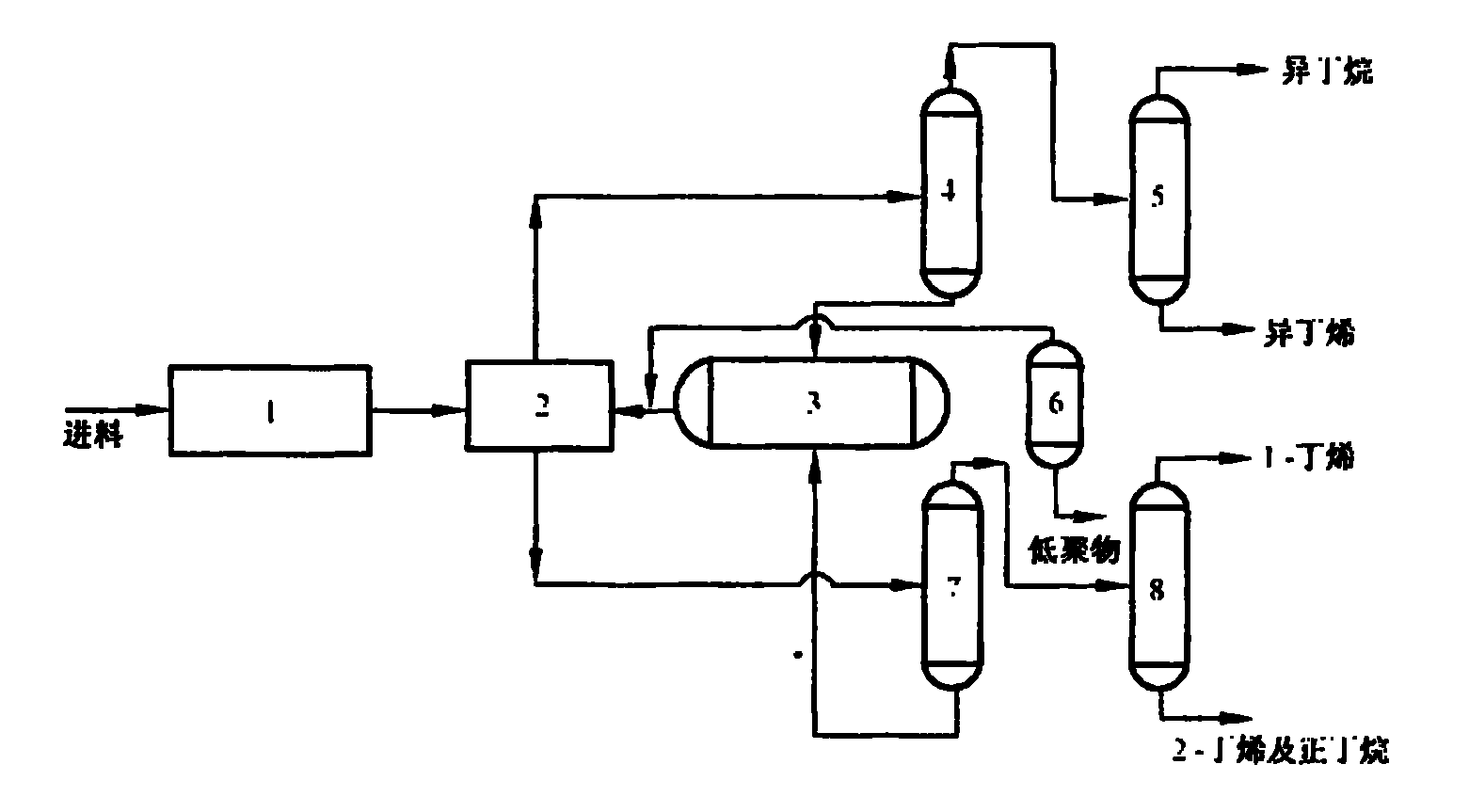

[0016] The 5A molecular sieve modified with calcium adopts the multi-stage bed adsorption method. In order for the adsorbent to process C4 materials continuously, there are three fixed bed adsorbers, that is, one reactor for adsorption, one for desorption and one for regeneration; the process of adsorption and desorption is at 100°C and 101.325kPa pressure conduct. The adsorption liquid is rectified to remove a small amount of n-butane and 2-butene, and the final 1-butene purity is >99.0%; the vaporized C4 material is passed into the first adsorption tower that has been washed with n-hexane in advance, At this time, the desorption of n-hexane occurs on the one hand, and the adsorption of n-butene occurs on the other hand; the desorbed n-hexane and isobutene are discharged from the top of the tower, and after isobutene is separated, n-hexane returns to the system for recycling. See the process for details figure 1 .

Embodiment 2

[0018] The 5A molecular sieve modified with calcium adopts the multi-stage bed adsorption method. In order for the adsorbent to process C4 materials continuously, there are three fixed bed adsorbers, that is, one reactor for adsorption, one for desorption and one for regeneration; the process of adsorption and desorption is at 100°C and 101.325kPa pressure conduct. The adsorption liquid is rectified to remove a small amount of n-butane and 2-butene, and the final 1-butene purity is >99.0%; the vaporized C4 material is passed into the first adsorption tower that has been washed with n-hexane in advance, At this time, the desorption of n-hexane occurs on the one hand, and the adsorption of n-butene occurs on the other hand; the desorbed n-hexane and isobutene are discharged from the top of the tower, and after isobutene is separated, n-hexane returns to the system for recycling. See the process for details figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com