Preparation method of epoxy resin composite material strengthened by in situ growth of CNT (carbon nano tube) on surface of quartz fibre

A technology of in-situ growth and epoxy resin, applied in the field of nanomaterials, can solve the problems of carbon nanotube dispersed interface bonding, carbon nanotube reinforced polymer effect is not good, etc., to improve the insufficient interlayer shear strength, preparation method Simple and easy to implement, the effect of improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

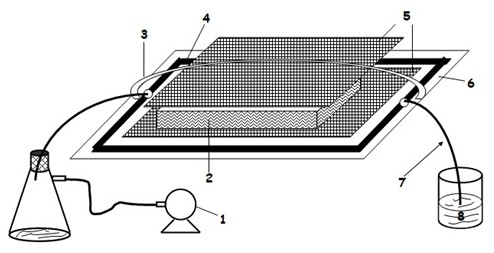

Method used

Image

Examples

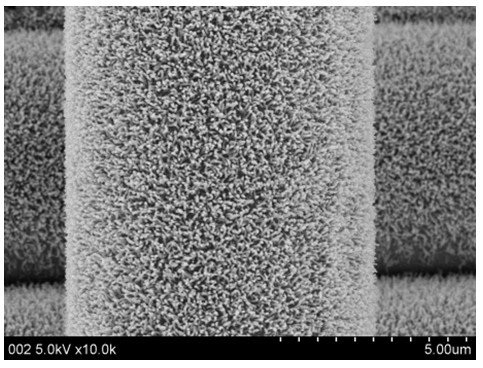

Embodiment 1

[0034] Configure 0.1mol / L Ni(NO 3 ) 2 Aqueous solution (absolute ethanol and isopropanol can also be used as the solvent), and the surface of the quartz fiber is covered with a catalyst layer by the impregnation method. Put it into a tube furnace and feed it with Ar, and heat it up. When the temperature rises to the set value (650°C), C 2 h 2 With a certain flow rate (Ar / C 2 h 2 =20: 1) Pass in, react for 5min, close C 2 h 2 , Ar cooled the tube furnace at a flow rate of 800mL / min. When the temperature dropped to room temperature, the black quartz fiber cloth was taken out. The obtained carbon nanotubes have an average diameter of 50 nm and a length of about 300 nm. The 15 pieces of fiber cloth obtained above were introduced into the fiber cloth by the vacuum-assisted resin transfer molding process, and the uniformly mixed epoxy resin and curing agent were heated up, and cured at 110°C for 3 hours, and the carbon nanotube fiber epoxy composite material was finally obtai...

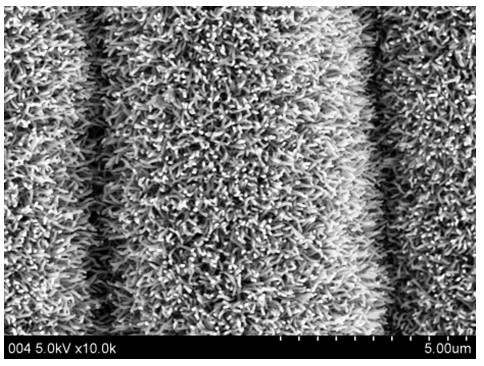

Embodiment 2

[0038] Configure 0.1mol / L Ni(NO 3 ) 2 Aqueous solution, the surface of the quartz fiber is covered with a layer of catalyst by impregnation method. Put it into a tube furnace and feed it with Ar, and heat it up. When the temperature rises to the set value (650°C), C 2 h 2 With a certain flow rate (Ar / C 2 h 2 =20:1) Pass in, react for 60min, close C 2 h 2 , Ar cooled the tube furnace at a flow rate of 800mL / min. When the temperature dropped to room temperature, the black quartz fiber cloth was taken out. The obtained carbon nanotubes have an average diameter of 50 nm and a length of about 1 μm. The 15 pieces of fiber cloth obtained above were introduced into the fiber cloth by the vacuum-assisted resin transfer molding process, and the uniformly mixed epoxy resin and curing agent were heated up, and cured at 110°C for 3 hours, and the carbon nanotube fiber epoxy composite material was finally obtained. The scanning electron micrographs of the interlayer shear of the com...

Embodiment 3

[0043] Configure 0.5mol / L Ni(NO 3 ) 2 Aqueous solution, the surface of the quartz fiber is covered with a layer of catalyst by impregnation method. Put it into a tube furnace and feed it with Ar, and heat it up. When the temperature rises to the set value (650°C), C 2 h 2 With a certain flow rate (Ar / C 2 h 2 =20:1) Pass in, react for 60min, close C 2 h 2 , Ar was used to cool the tube furnace at a flow rate of 800mL / min. When the temperature dropped to room temperature, the black quartz fiber cloth was taken out. The obtained carbon nanotubes have an average diameter of 45 nm and a length of about 500 nm. The 15 pieces of fiber cloth obtained above were introduced into the fiber cloth by vacuum-assisted resin transfer molding process, and the uniformly mixed epoxy resin and curing agent were heated up and cured at 110°C for 3 hours to finally obtain the carbon nanotube fiber epoxy composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com