Revolving-scraper type biomass pyrolysis reactor

A biomass thermal cracking, rotating scraper technology, applied in the fields of biofuels, special forms of dry distillation, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of long process, high cost, low production efficiency, etc., to reduce secondary cracking, Increased productivity and material savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

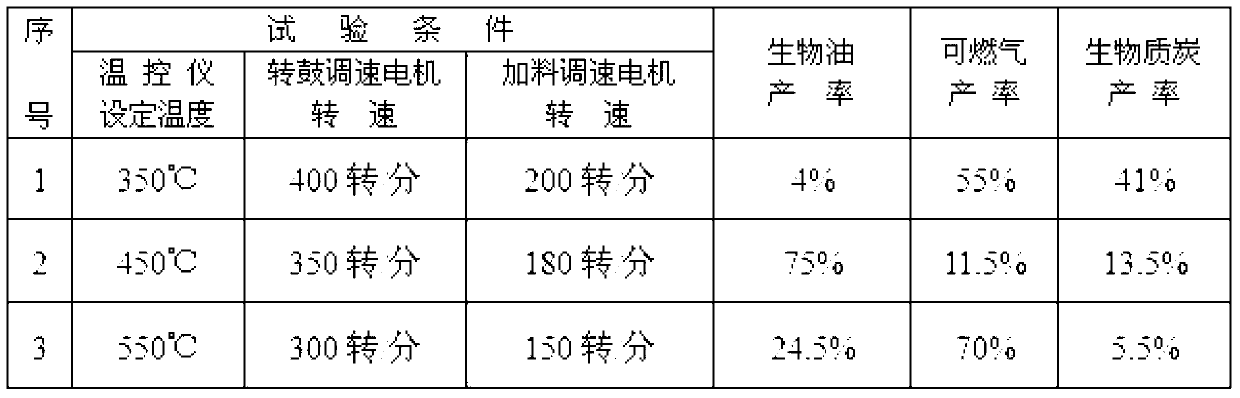

Embodiment 1

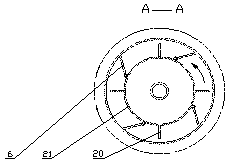

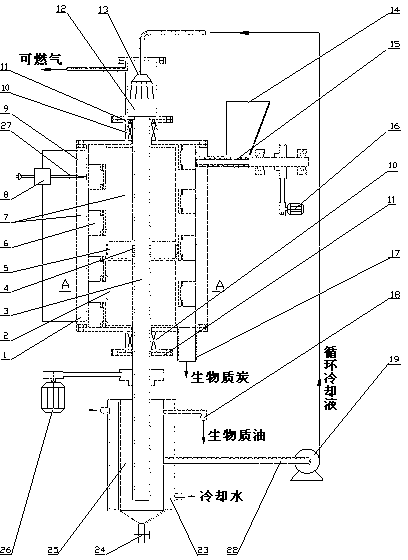

[0026]A rotary scraper type biomass pyrolysis reactor of the present invention is composed of a heating cylinder 1, a rotating drum 2, a temperature controller 8, a dynamic seal 10, a bearing 11, a spray head 13, a hopper 14, a feeding screw 15, a feeding Composed of motor 16, circulating pump 19, circulating coolant pipeline 22, oil-water collection tube 25, etc.; the central shaft of the drum 2 is provided with a rotating shaft 3, and the heating drum 1 is fixedly installed on the rotating shaft 3 of the drum 2 to rotate On the outside of the drum 2, an electric heating wire 9, a thermocouple 27 and a temperature controller 8 are installed on the outside of the heating cylinder 1. The signal output line of the thermocouple 27 is connected to the temperature controller 8, and the electric power output terminal of the temperature controller 8 Connected with the heating wire 9, the outer surface of the heating wire 9 is wrapped with thermal insulation cotton 7; above the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com