Microwave and steam cooking two-purpose microwave oven

A microwave oven and microwave technology, which is applied in the directions of steam generation, household stoves/stoves, steam generation methods, etc., can solve the problems that microwave and steam heating cannot be performed at the same time, the advantages of microwave ovens cannot be exerted, and the use range is narrow, so as to improve the utilization rate and Energy saving effect, widening range of use, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

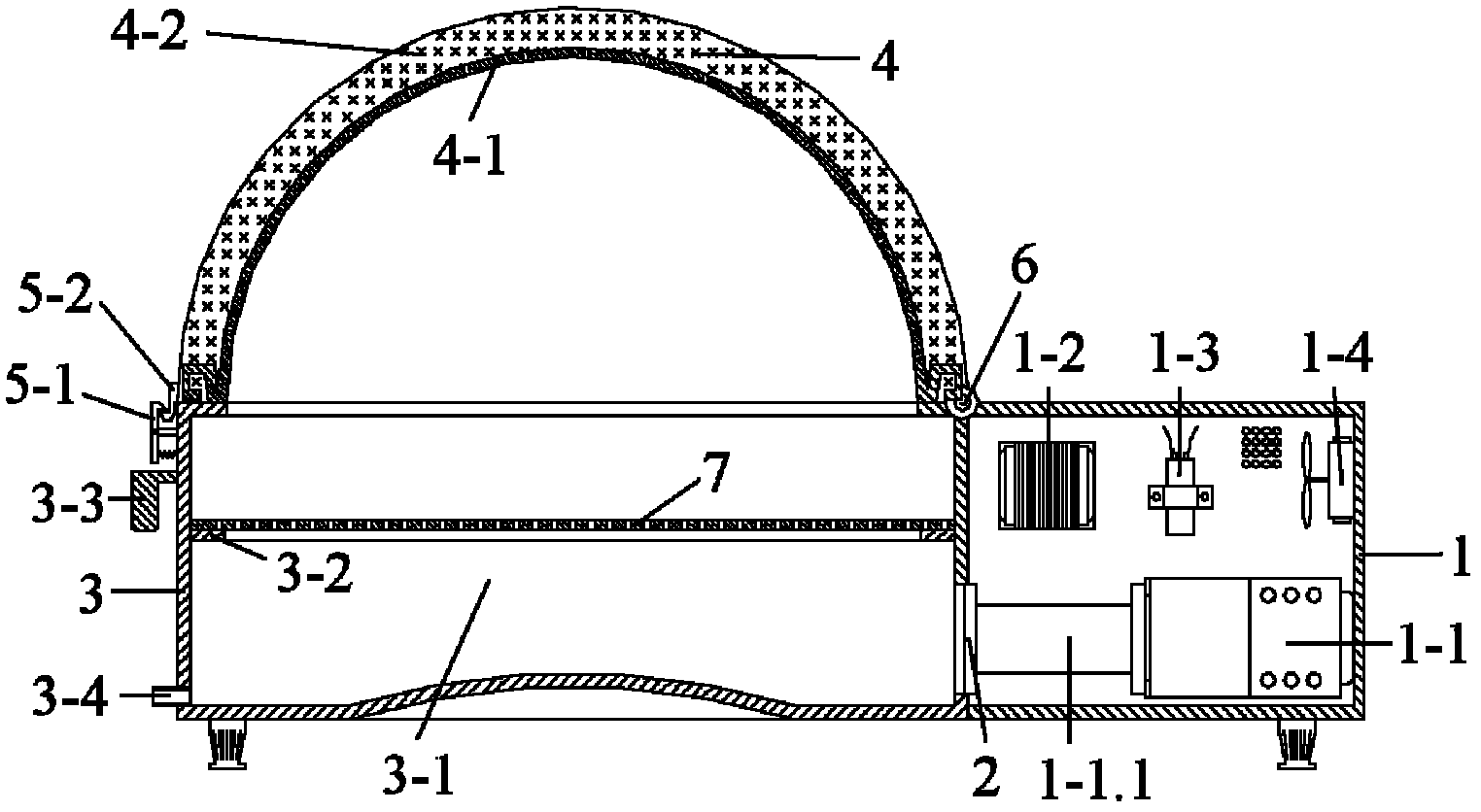

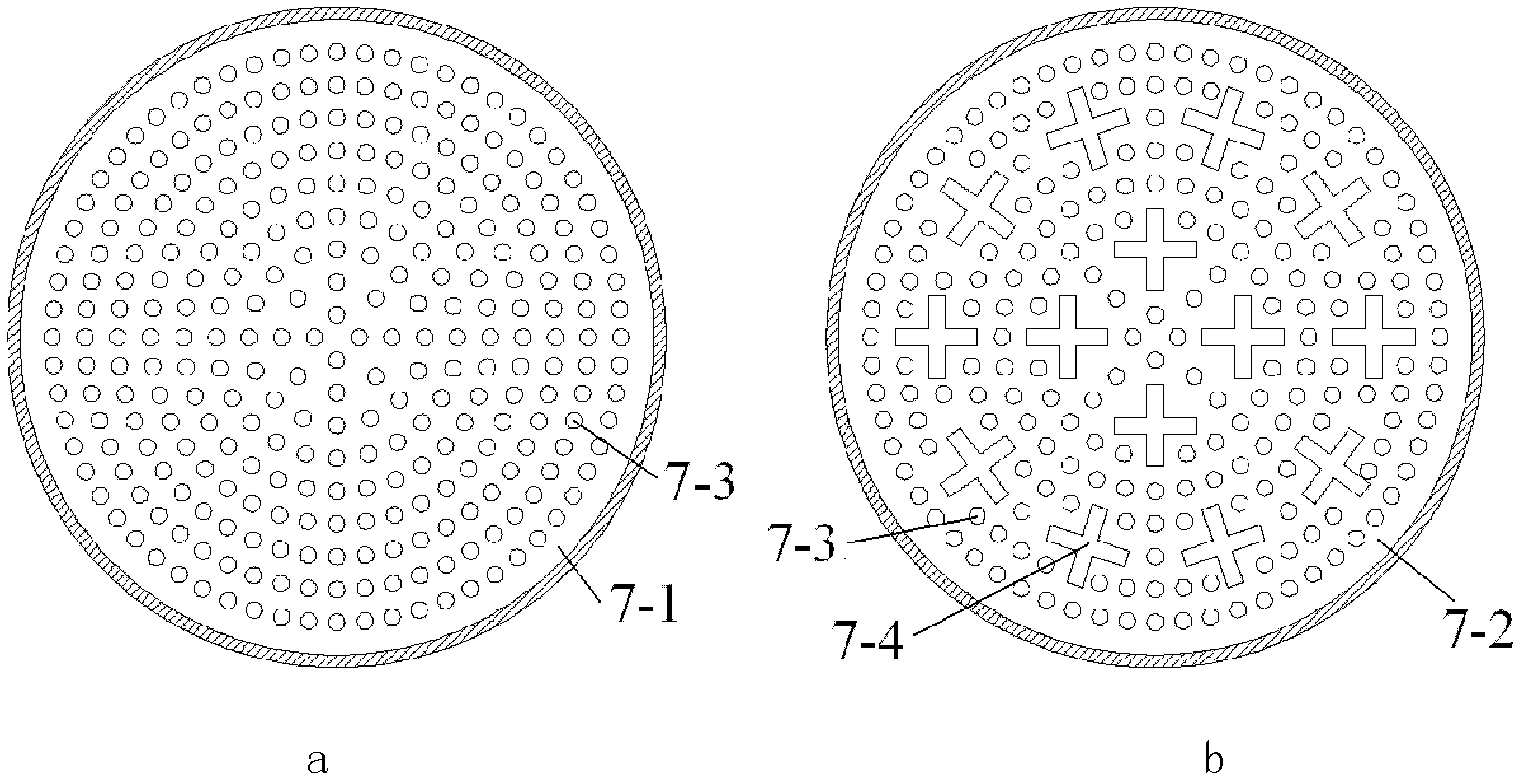

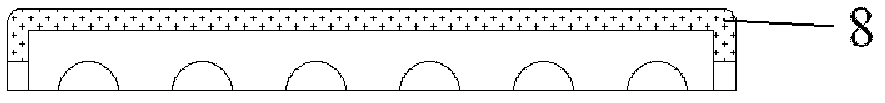

[0012] Embodiment 1: The microwave generation and control box 1 of this embodiment directly adopts the microwave generation and control box used by the KD23B-DA microwave oven (manufactured by "Midea"). The output power of the microwave is 900W, and the microwave frequency is 2458MHz (wavelength is 122mm ); the separation plate 2 adopts (length × width × thickness) polytetrafluoroethylene plate of 120 × 60 × 1mm (millimeter), and is sealed and fixed with the furnace body 3 through silicon rubber; the furnace body 3 adopts a 2mm thick Stainless steel plate, the outer diameter is Φ304mm, the height of the working chamber 3-1 is 200mm, and an annular steamer seat 3-2 with a radial width of 5 mm is set on the inner wall 150mm away from the bottom of the working chamber. The working chamber 3-2 of this embodiment The bottom of 1 adopts a spherical crown-shaped convex surface with a radius of R500mm, and the arch height of the convex surface is 15mm. The diameter of the upper mouth o...

Embodiment 2

[0015] In this embodiment, other parameters are the same as those in Embodiment 1 except that the bottom surface of the microwave working cavity 3-1 is flat and the bracket 8 is omitted. In this embodiment, when microwaves are directly used to heat food, the microwave heating container can be directly placed on the bottom surface of the working cavity 3-1 without supporting the support 8 for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com