Adaptive micro-perforated plate sound absorber and real-time micropore adjusting method thereof

A technology of micro-perforated plate and self-adaptive controller, which is applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of fixed effective sound absorption center frequency, limited sound absorption capacity, and noise signal frequency bandwidth, etc., and achieves a simple structure and production process. , Acoustic impedance is easy to match, and the effect of broadening the sound absorption frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

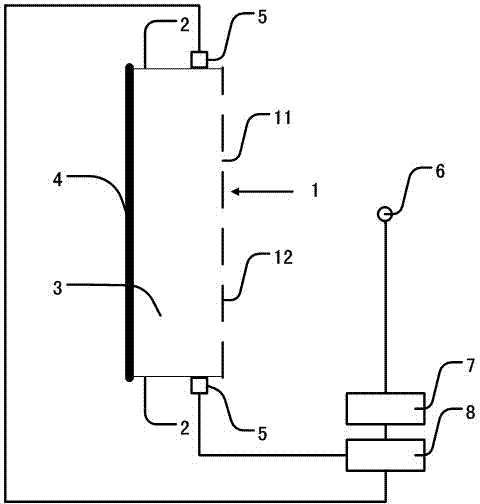

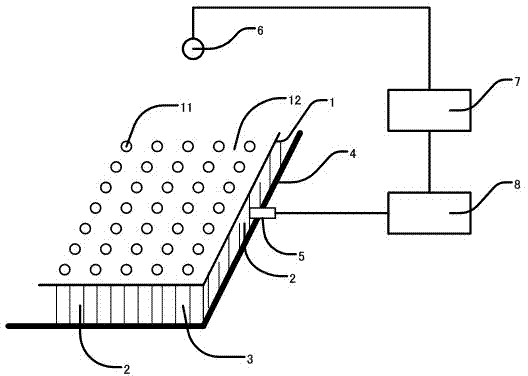

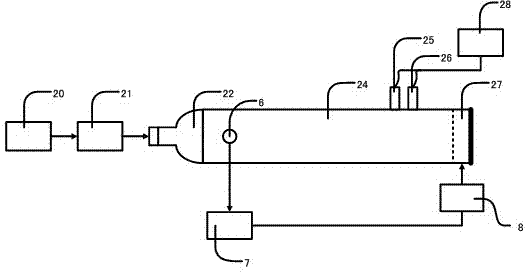

[0030] Such as figure 1 and figure 2 As shown, for a specific embodiment, the piezoelectric film micro-perforated plate resonant sound-absorbing structure includes a piezoelectric film micro-perforated plate 1 with adjustable micropore diameter formed by a piezoelectric film 12 covered with micropores 11 . The cavity formed by the piezoelectric film micro-perforated plate 1 and its surrounding side walls 2 and rear wall 4 is the resonant sound-absorbing structure of the piezoelectric film micro-perforated plate. Circuit components such as noise detector 6, adaptive controller 7 and piezoelectric film drive circuit 8 constitute an active control circuit. The active control circuit and the resonant sound-absorbing structure of the piezoelectric film micro-perforated plate constitute an adaptive micro-perforated plate sound absorber.

[0031]The noise detector 6 can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com