Process for the production of propylene random copolymers for injection moulding applications

A random copolymer, polypropylene technology, applied in thin-walled packaging, random copolymer itself and its application field, can solve the problems of low rigidity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0146] method:

[0147] The melt flow rate:

[0148] Melt flow rate is the MFR of polypropylene measured according to ISO 1133 (230°C, 2.16 kg load) unless otherwise stated 2 , and take g / 10min as the unit. MFR is an indication of the flowability and processability of a polymer. The higher the melt flow rate, the lower the viscosity of the polymer.

[0149] Comonomer content:

[0150] Comonomer content according to 13 C-NMR is measured by standard Fourier transform infrared spectroscopy (FTIR). When determining the ethylene content in polypropylene, film samples (thickness about 250 mm) were prepared by hot pressing. -CH 2 - Absorption peak (800-650cm -1 ) area was measured with a Perkin Elmer FTIR 1600 spectrometer. The method by 13 The ethylene content data determined by C-NMR were calibrated.

[0151] Xylene solubles:

[0152] The fraction of xylene solubles (XS) described and defined in the present invention is determined as follows: 2.0 g of polymer are dissol...

Embodiment 1-3

[0187] Polymerization and polymer properties:

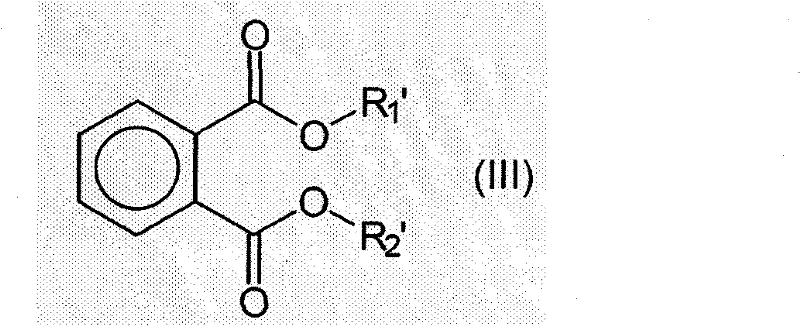

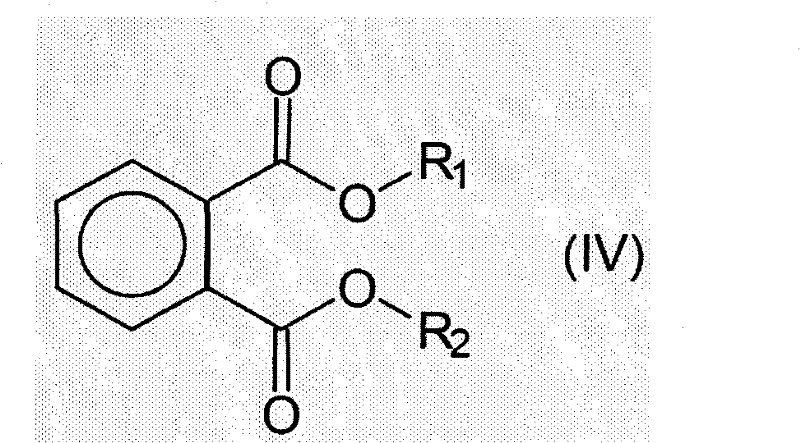

[0188] Polymerization was carried out in liquid propylene in a pilot plant loop reactor. Polymerization conditions and polymer properties are given in Table 1. The catalyst used in the polymerization reaction is prepared according to WO 92 / 19653 using DOP as dialkyl phthalate of general formula (III) and ethanol as alcohol, the cocatalyst is triethylaluminum (TEA) and can Diethylaminotriethoxysilane was used as external electron donor (ED). Proper concentrations of hydrogen are used for melt flow control.

[0189] Table 1:

[0190] unit

Embodiment 4 and 5

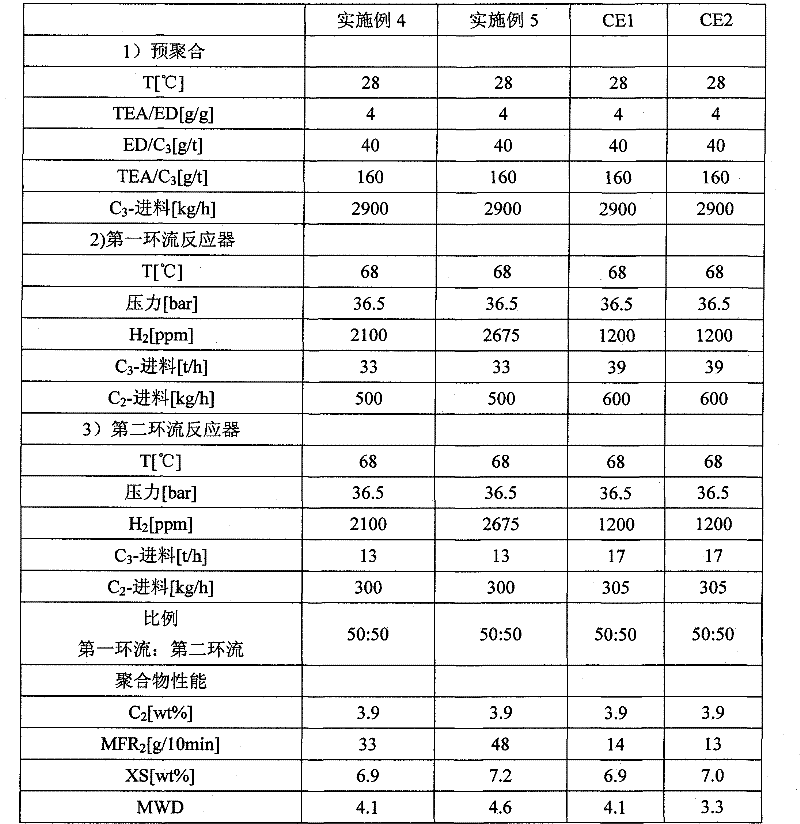

[0191] Examples 4 and 5, Comparative Examples CE1 and CE2

[0192] Polymerization takes place in a Spheripol consisting of a prepolymerization reactor and two loop reactors connected in sequence carried out in the device. The catalyst used in the polymerization reaction is prepared according to WO 92 / 19653 using DOP as dialkyl phthalate of general formula (III) and ethanol as alcohol, the cocatalyst is triethylaluminum (TEA) and can Cyclohexylmethyldimethoxysilane was used as external electron donor (ED). Proper concentrations of hydrogen are used for melt flow control.

[0193] Polymerization conditions and polymer properties are given in Table 2.

[0194] Table 2:

[0195]

[0196] The base resins of Comparative Examples CE1 and CE2 were subjected to peroxide degradation at 220° C. with 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (DHBP from Degussa) ( visbreaking). The MFR rose to 30 g / 10 min for CE1 and 45 g / 10 min for CE2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com