Reclaiming device and separation method for heavy component residue of coked crude benzene hydrogenation process

A technology for coking crude benzene and heavy components, applied in distillation purification/separation, organic chemistry, etc., can solve the problems of large gaps in benzene raw materials, and achieve the effects of high product purity, low operating temperature, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

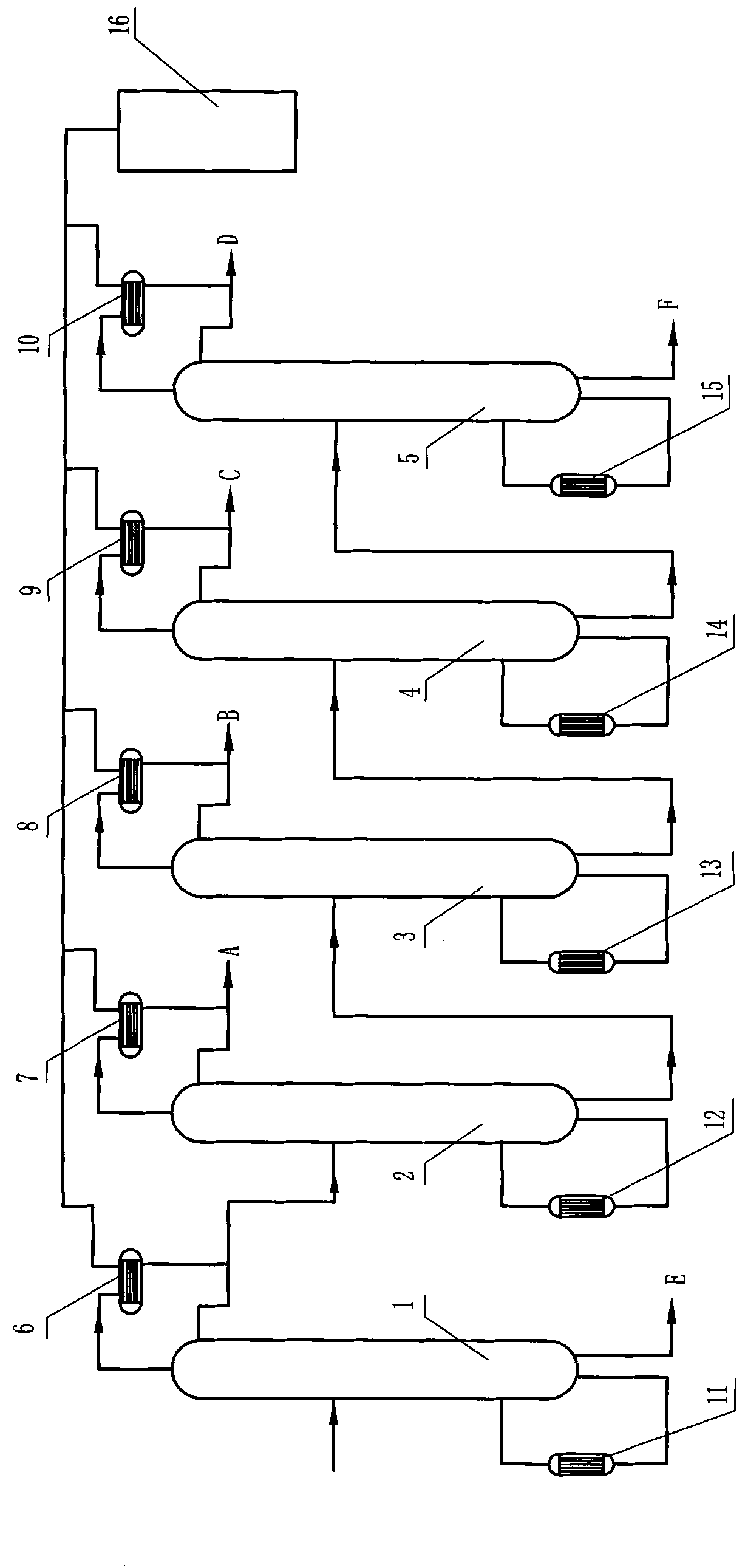

[0020] see figure 1 , the present invention comprises weight removal tower 1, light removal tower 2, trimethylbenzene tower 3, indane tower 4 and tetralin tower 5; Feed port is communicated; the outlet at the bottom of the light removal tower 2 and the feed inlet in the middle of the trimethylbenzene tower 3, the outlet at the bottom of the trimethylbenzene tower 3 and the middle feed inlet of the indane tower 4, The outlet at the bottom of the indane tower 4 is communicated with the middle feed inlet of the tetralin tower 5 through pipelines respectively; Device 12, trimethylbenzene tower reboiler 13, indane tower reboiler 14 and tetralin tower reboiler 15 are communicated with, and the tower top of each tower is respectively connected with weight-removing tower condenser 6, light-removing tower condenser 7, The trimethylbenzene tower condenser 8, the indane tower condenser 9 and the tetralin tower condenser 10 are in communication, and each of the above-mentioned condenser...

Embodiment 2

[0024] The separation and purification process of the present invention will be described below with the separation and purification process of the heavy component raffinate in the coking crude benzene hydrogenation process of a certain plant.

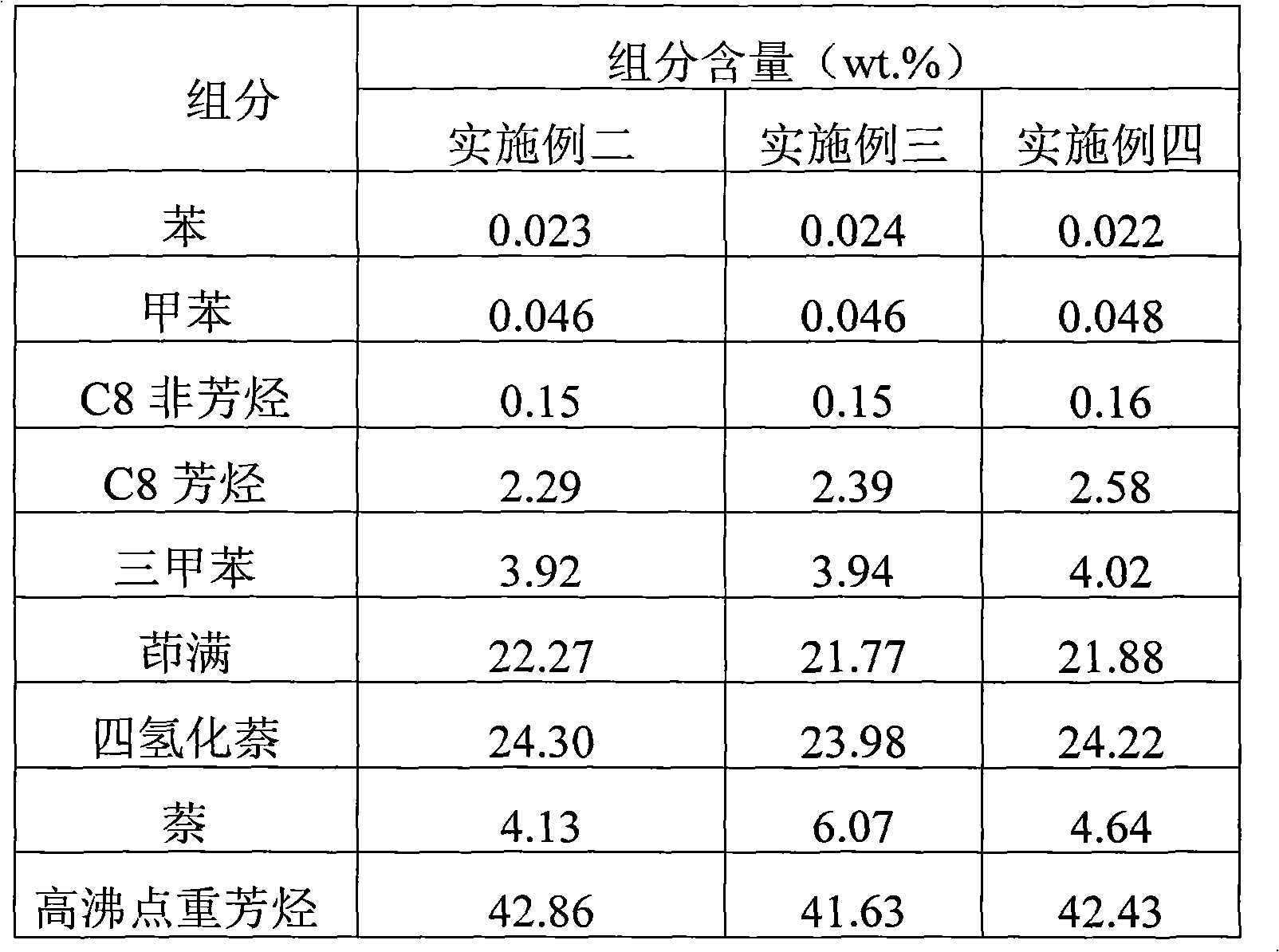

[0025] The material composition of the heavy component raffinate produced by the coking crude benzene hydrogenation process is shown in Table 1.

[0026] Separation steps:

[0027] ①The heavy component raffinate produced by the coking crude benzene hydrogenation process is fed into the weight removal tower 1 at a flow rate of 6250kg / h. The operating pressure at the top of the tower is 5kPa, the temperature at the top of the tower is 100°C, the temperature at the bottom of the tower is 170°C, and the reflux ratio It is 0.5: 1, and the high-boiling point heavy aromatics cut E with higher boiling point than naphthalene is discharged from the bottom of the tower, and the mixed cut mainly containing xylene, trimethylbenzene, indane, tetrali...

Embodiment 3

[0035] The material composition of the heavy component raffinate of the coking crude benzene hydrogenation process in a factory is shown in Table 1, and its separation steps:

[0036] ① Add the heavy component raffinate produced by the coking crude benzene hydrogenation process to the weight removal tower 1 at a flow rate of 6250kg / h. The operating pressure at the top of the weight removal tower 1 is 20kPa, the temperature at the top of the tower is 110°C, and the temperature at the bottom of the tower is 180 ℃, the reflux ratio is 1.5: 1, the high-boiling heavy aromatics fraction E with a higher boiling point than naphthalene is discharged from the bottom of the tower, and the mixed fraction mainly containing xylene, trimethylbenzene, indane and tetralin is obtained from the top of the tower;

[0037] ② Step ① The mixed fraction obtained at the top of the tower is sent from the middle to the light removal tower 2, the operating pressure at the top of the light removal tower 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com