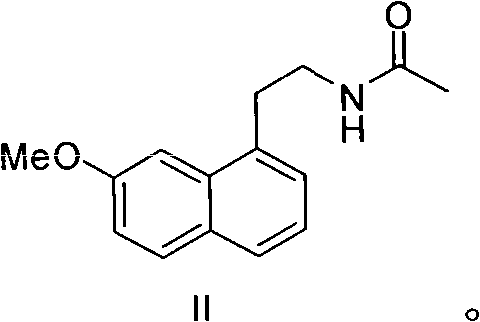

Preparation method of 2-(7-methoxy-1-naphthyl) acetonitrile

A methoxyl and naphthyl technology, applied in a new preparation field, can solve the problems of harsh reaction requirements, environmental pollution, incomplete reaction, etc., and achieve the effects of mild reaction conditions, high product purity, and short reaction route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

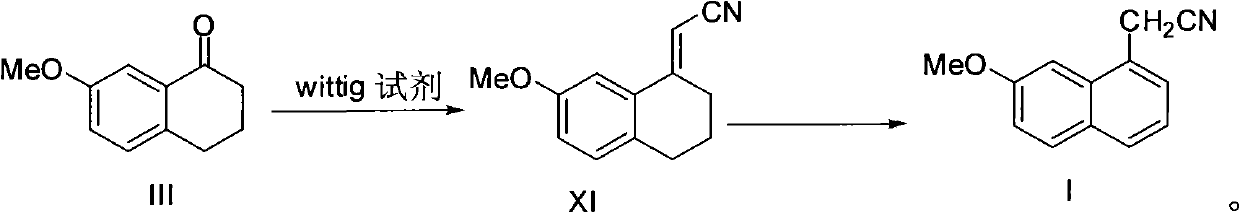

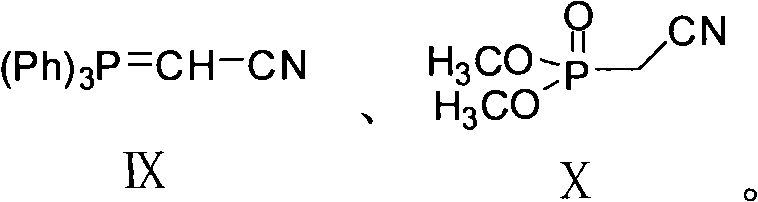

[0030] Dissolve 35.2 g of compound III (7-methoxytetralone) and 60.2 g of compound IX in 340 ml of toluene, heat to 100° C. until the raw materials disappear, and cool to room temperature. Wash and dry. The solvent was distilled off to obtain 36.0 g of compound XI. Yield: 90%. ESI-MS: [M+H] + 200.

Embodiment 2

[0032]

[0033] Dissolve 35.2 g of compound III (7-methoxytetralone) and 30.0 g of compound X in 170 ml of toluene, carefully add 13.6 g of sodium ethoxide, heat to 100°C until the raw materials disappear, and cool to room temperature. Wash and dry. The solvent was distilled off to obtain 36.5 g of compound XI. Yield: 91%. ESI-MS: [M+H] + 200.

Embodiment 3

[0035]

[0036] 36.0 g of compound XI prepared in Example 1 and 7.2 g of 10% Pd / C were dissolved in 180 ml of toluene, heated to reflux until the raw materials disappeared, and cooled to room temperature. Suction filtration, washing and drying. The solvent was distilled off to obtain the target compound I (30.6 g). Yield: 85%. Melting point: 83-84°C. ESI-MS: [M+H] + 198. 1 H-NMR (CDCl 3 , ppm): 7.20-7.79 (m, 5H, ArH), 7.0 (d, 1H, J=2.1Hz, ArH), 4.1 (s, 2H, ArCH 2 ), 3.94 (3, 3H, OCH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com