Colored system

A system and color technology, applied in the field of color systems, to achieve the effects of eliminating side reactions, reducing hazards, and increasing flexibility in preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0059] Example 1: Preparation of polymer-coated aluminum substrates by ATPR

[0060] Take 4.8 kg of lenticular aluminum pigment SSP-695 from Silberline Mfg. Company with a solid content of 75.68%, and add 11.64 kg of glycol ether PM acetate to a 20-liter reaction flask. The mixture was stirred until homogeneous, then heated to 80°C. Another 16 ml of ATRP initiator 3-(trimethylsilylpropyl)-2-bromo-2-methylpropionate was added. After reacting at 80°C for 6 hours, it was cooled to room temperature and filtered to obtain a solid. The solids content of the final product was 64.56% by weight.

[0061] Get above-mentioned fixed product 30.8 grams of initiator, be dispersed in the 310ml glycol ether PM acetate that is contained in the 500ml reaction bottle. 80 ml of N,N-dimethylaminoethyl methacrylate (DMAEMA) was added with moderate stirring. The reaction bottle was sealed, and high-purity nitrogen gas was introduced from the bottom of the bottle to make the system in an inert at...

example 2

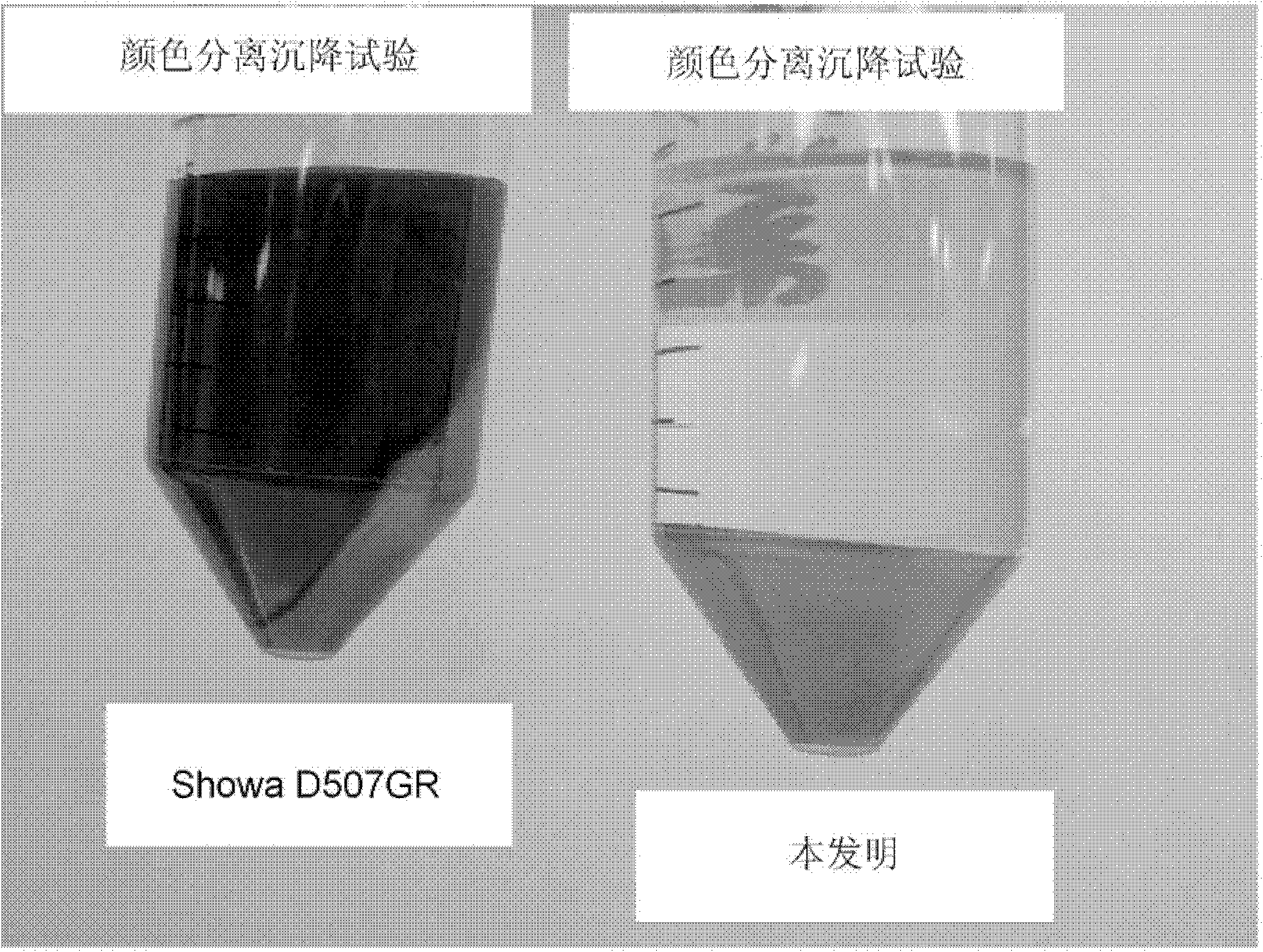

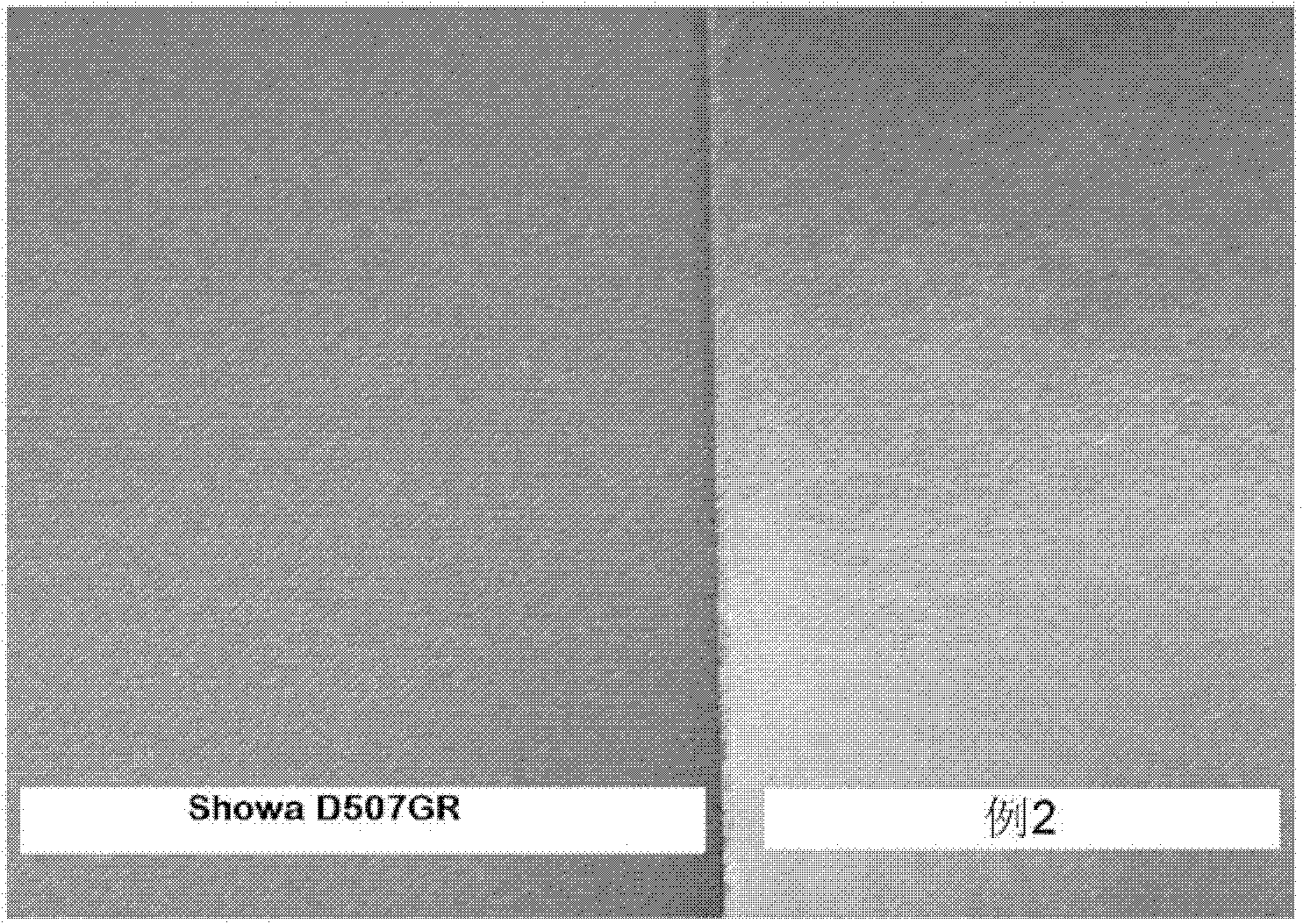

[0064] Example 2: Preparation of green aluminum color system

[0065] 4.35 grams of the polymer-coated aluminum pigment prepared in Example 1 was dispersed into a 40 ml vial containing 15.0 grams of NMP. Another 0.40 g of phthalocyanine green-pigment green 7 (PG7) solid dispersion (40% by weight of pigment particles dispersed in polyvinyl chloride / polyvinyl acetate copolymer) was dispersed into 5.0 g of NMP. This PG7 dispersion was added to the previous aluminum pigment dispersion, followed by 4.0 grams of a 4% allyl bromide solution in NMP. The resulting mixture was stirred at room temperature for 15 minutes and then warmed to 90°C over about 30 minutes. Stir for a further 15 minutes at 90°C, then cool to room temperature. The solid obtained by centrifugation was redispersed twice in NMP and centrifuged again, and the supernatant after each centrifugation was only very light green, while the solid sediment was bright dark green.

example 3

[0066] Example 3: Preparation of blue aluminum color system

[0067] 4.35 grams of the polymer-coated aluminum pigment prepared in Example 1 was dispersed into a 40 ml vial containing 15.0 grams of NMP. Another 0.40 g of phthalocyanine blue-pigment blue 15:4 (PB15:4) solid dispersion (40% by weight of pigment dispersed in polyvinyl chloride / polyvinyl acetate copolymer) was dispersed into 5.0 g of NMP. This PB15:4 dispersion was added to the previous aluminum pigment dispersion, followed by 4.0 grams of a 4% allyl bromide solution in NMP. The resulting mixture was stirred at room temperature for 15 minutes and then warmed to 90°C over about 30 minutes. Stir for a further 15 minutes at 90°C, then cool to room temperature. The solids obtained by centrifugation were redispersed twice in NMP and centrifuged again, and the supernatant after each centrifugation was only very light blue, while the solid sediment was bright dark blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com