A device and method for preparing cyclic carbonates integrating absorption, separation and catalytic reaction

A cyclic carbonate and catalytic reaction technology, applied in thin-film liquid-gas reaction, organic chemistry, etc., can solve the problems of low energy consumption, reduce equipment investment, etc., achieve high economic value, reduce energy consumption, overcome the The effect of catalyst separation from product and feedstock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

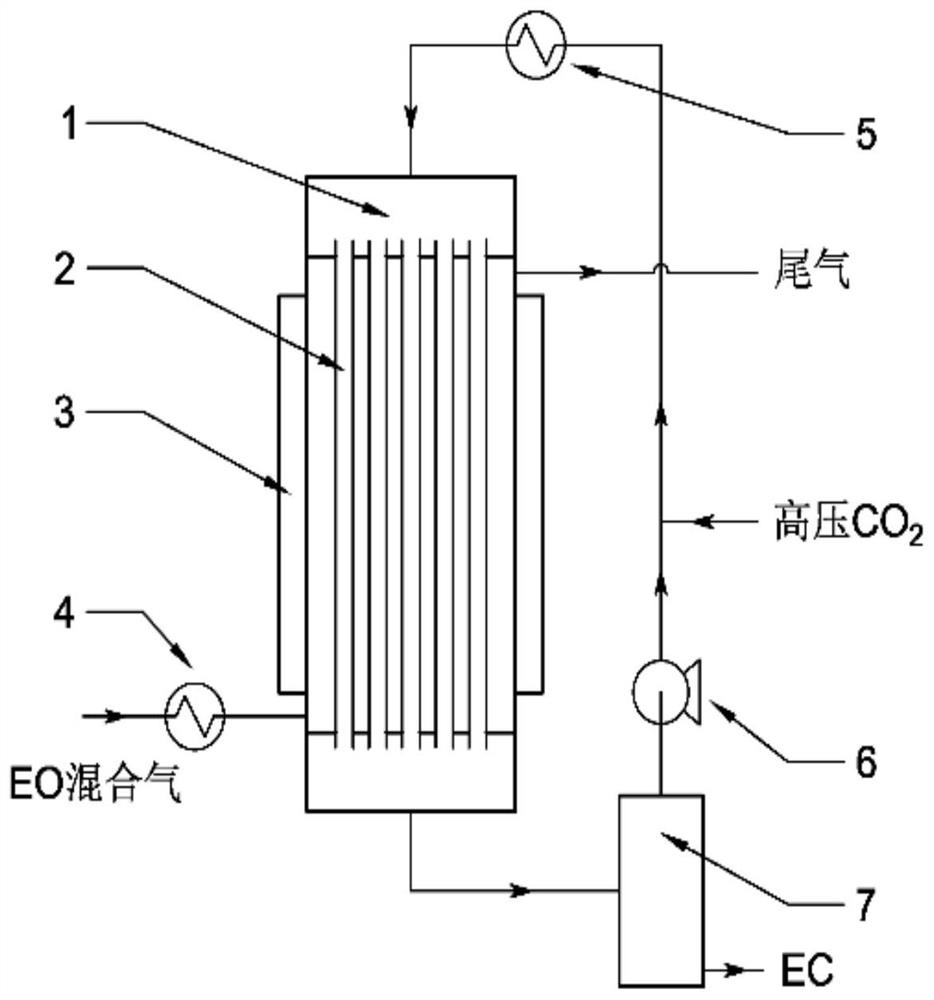

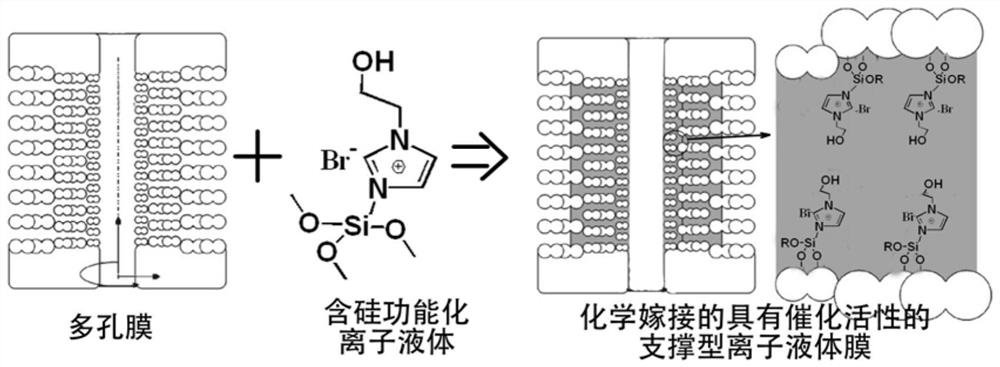

[0084] The device and flow diagram of the preparation of cyclic carbonate provided by the invention are as follows figure 1 As shown: the device includes an ionic liquid membrane reactor; the ionic liquid membrane reactor includes a reactor body 1 and an ionic liquid membrane 2; the ionic liquid membrane 2 divides the inside of the reactor body 1 into an isolated cavity; The device also includes a reactor heating device 3, an alkylene oxide heat exchanger 4 and a carbon dioxide heat exchanger 5; the device also includes a gas-liquid separator 7 connected to the ionic liquid membrane reactor, and is arranged at the Circulation pump 6 between the outlet of device 7 and the inlet of reactor main body 1.

[0085] Its technological process includes the following steps:

[0086] A certain concentration of ethylene oxide mixed gas is preheated by the alkylene oxide heat exchanger 4 and then passed into the shell gas path cavity of the main body 1 of the ionic liquid membrane reactor...

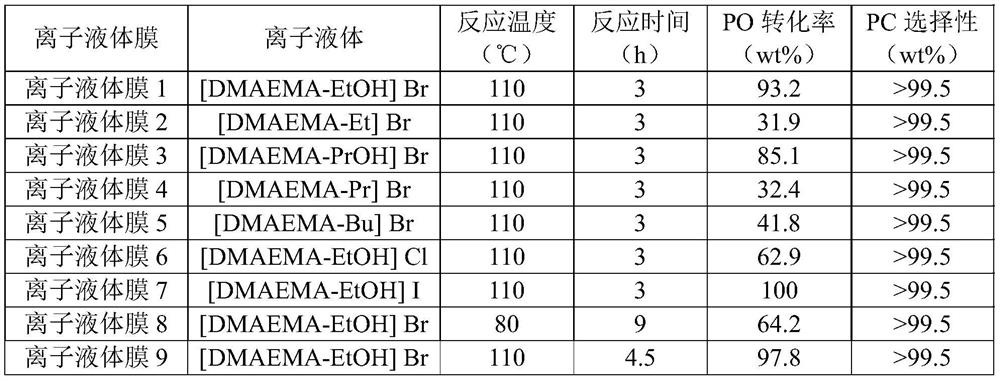

Embodiment 1

[0112] This embodiment provides a device for preparing cyclic carbonates that integrates absorption, separation and catalytic reactions. The device includes an ionic liquid membrane reactor, and the ionic liquid membrane reactor includes a reactor body and an ionic liquid membrane. The ionic liquid membrane is a [DMAEMA-EtOH]Br ionic liquid membrane 1 formed in the form of copolymerization, and 20 groups of ionic liquid membranes 1 form a tube bundle and are loaded into a membrane module to obtain a tubular membrane reactor. It is divided into 21 separated cavities, namely the first gas path cavity and the second gas path cavity, and there is a transmembrane pressure difference between the first gas path cavity and the second gas path cavity.

[0113] The device also includes a reactor jacket heat exchange device, the device also includes an alkylene oxide heat exchanger and a carbon dioxide heat exchanger, and a gas-liquid separator connected to the ionic liquid membrane react...

Embodiment 2

[0115] This embodiment provides a device for preparing cyclic carbonates that integrates absorption, separation and catalytic reactions. The device includes an ionic liquid membrane reactor, and the ionic liquid membrane reactor includes a reactor body and an ionic liquid membrane. The ionic liquid membrane is an ionic liquid membrane 14, and five groups of plate-type ionic liquid membranes 14 are packed into a membrane module to obtain a plate-and-frame membrane reactor. The frame-type membrane reactor is divided into 6 separated cavities, respectively The gas path cavity and the second gas path cavity, there is a transmembrane pressure difference between the first gas path cavity and the second gas path cavity.

[0116] The device also includes a coil heat exchanger inside the reactor, the device also includes an alkylene oxide heat exchanger and a carbon dioxide heat exchanger, and a gas-liquid separator connected with the ionic liquid membrane reactor; the gas-liquid separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com