Process for bleaching needlebush and hardwood mixed chemical pulp stewed by using sodium hydroxide anthraquinone method

A technology of sodium hydroxide and anthraquinone method, which is applied in the field of bleaching technology, and can solve problems such as loss of yield, difficulty in cooking, and high hardness of pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

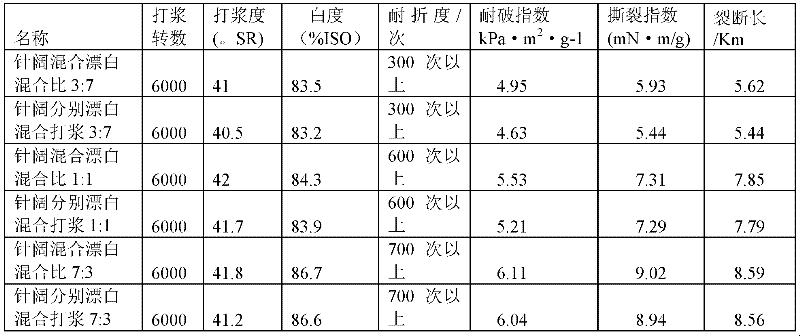

Embodiment 1

[0040] The softwood chemical pulp cooked by the sodium hydroxide anthraquinone method and the hardwood chemical pulp cooked by the sodium hydroxide anthraquinone method are mixed according to the ratio range of 3:7 in mass ratio, and then bleached according to the following steps:

[0041] (1) Wash the raw pulp mixed in proportion with tap water or groundwater (the same below), put the mixed raw pulp of needle broadleaf into the reaction kettle of oxygen delignification, add NaOH, MgSO 4 Adjust the pH value to 11, feed oxygen, and carry out O at 95°C under 0.5MPa pressure. 1 Stage oxygen delignification, time 20min; NaOH dosage is 1.7% of dry pulp mass, MgSO 4 The dosage is 0.5% of the dry pulp mass, and the oxygen consumption is 1.6% of the dry pulp mass;

[0042] (2) The pulp obtained in step (1) is washed, and the washed pulp is added to the reaction kettle of oxygen delignification again, and NaOH and MgSO are added. 4 Adjust the pH value to 13, feed oxygen, and carry ou...

Embodiment 2

[0048] The softwood chemical pulp cooked by the sodium hydroxide anthraquinone method and the hardwood chemical pulp cooked by the sodium hydroxide anthraquinone method are mixed according to the ratio range of 1:1 by mass ratio, and then bleached according to the following steps:

[0049] (1) Wash the raw pulp mixed in proportion, put the mixed raw pulp of needle broadleaf into the reaction kettle of oxygen delignification, add NaOH, MgSO 4 Adjust the pH value to 12, feed oxygen, and carry out O at 90°C under 0.7MPa pressure. 1 Stage oxygen delignification, time 15min; NaOH dosage is 2.2% of dry pulp mass, MgSO 4 The dosage is 0.5% of the dry pulp mass, and the oxygen dosage is 1.2% of the dry pulp mass;

[0050] (2) The pulp obtained in step (1) is washed, and the washed pulp is added to the reaction kettle of oxygen delignification again, and NaOH and MgSO are added. 4 Adjust the pH value to 11, feed oxygen, and carry out O at a temperature of 95°C and a pressure of 0.4MP...

Embodiment 3

[0056] The softwood chemical pulp cooked by the sodium hydroxide anthraquinone method and the hardwood chemical pulp cooked by the sodium hydroxide anthraquinone method are mixed according to the ratio range of 7:3 by mass, and then bleached according to the following steps:

[0057] (1) Wash the raw pulp mixed in proportion, put the mixed raw pulp of needle broadleaf into the reaction kettle of oxygen delignification, add NaOH, MgSO 4 Adjust the pH value to 13, feed oxygen, and carry out O at 90°C under 0.5MPa pressure. 1 Stage oxygen delignification, time 15min; NaOH dosage is 2.2% of dry pulp mass, MgSO 4 The dosage is 0.5% of the dry pulp mass, and the oxygen dosage is 1.2% of the dry pulp mass;

[0058] (2) The pulp obtained in step (1) is washed, and the washed pulp is added to the reaction kettle of oxygen delignification again, and NaOH and MgSO are added. 4 Adjust the pH value to 11, feed oxygen, and carry out O 2 Stage oxygen delignification, time 90min; the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com