Micro-focus X-ray precise perspective imaging detection equipment

An imaging detection and X-ray technology, applied in the field of non-destructive automatic detection equipment, can solve the problems of poor stability of high-voltage power supply, inability to complete multi-angle three-dimensional detection, poor resolution, etc., and achieve the effect of improving real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

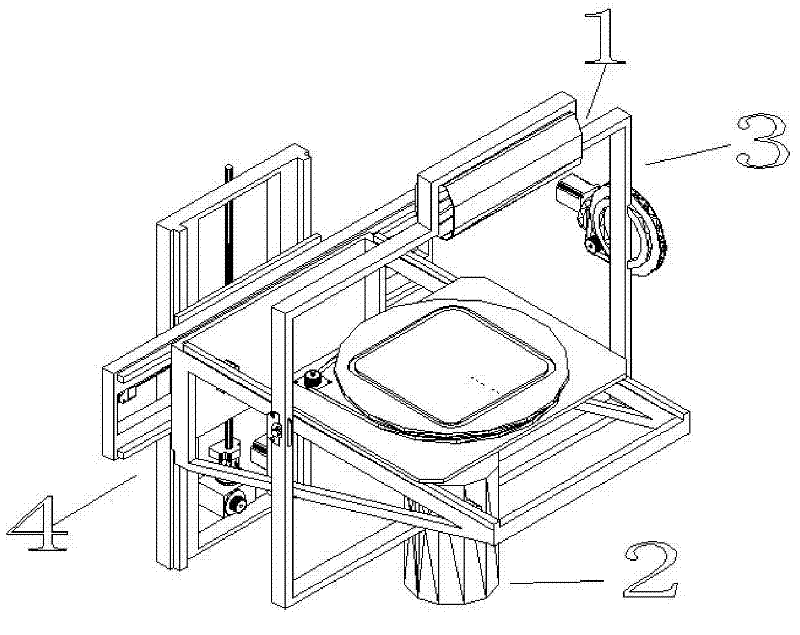

[0043] Such as figure 1 , Figure 12 As shown, the micro-focus X-ray precision fluoroscopic imaging detection equipment of the present invention includes a micro-focus X-ray source, a radiographic receiver, a multi-angle rotating three-dimensional detection device for the X-ray emission source and receiver, a four-axis motion platform for the measured object, and a computer And the five functional parts of the layered control (image processing and motion control) system.

[0044] A microfocus X-ray source.

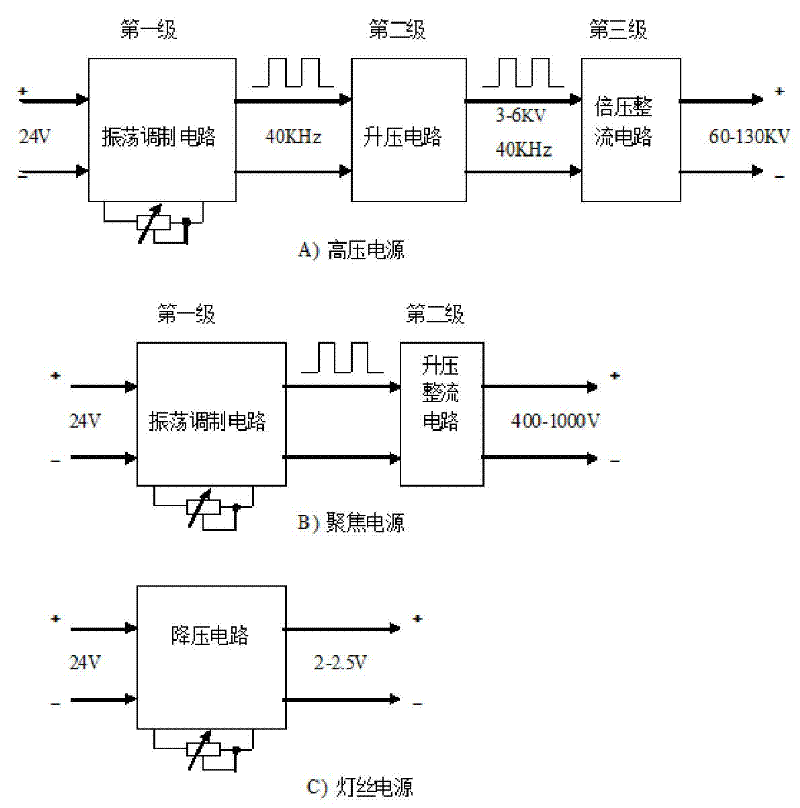

[0045] It consists of a micro-focus X-ray tube and a corresponding power supply.

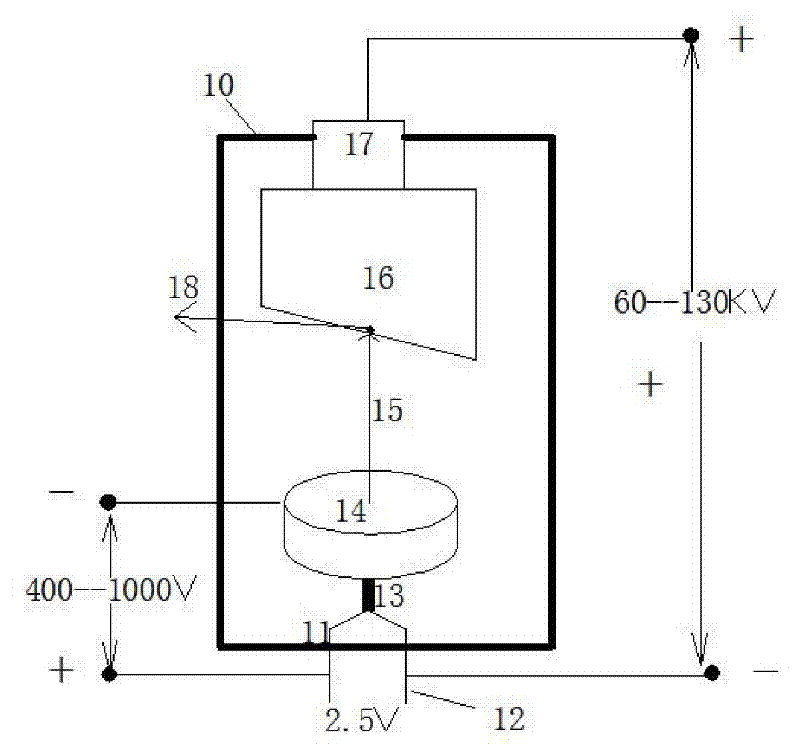

[0046] Such as figure 2 In the X-ray tube structure and working principle diagram shown, the micro-focus X-ray tube is a cylindrical glass tube 10 with internal vacuum, which is composed of a filament pole, a focusing pole and an anode.

[0047] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com