Method for manufacturing ultrahigh-frequency radio frequency identification (RFID) tag

A technology of RFID tags and manufacturing methods, applied in the field of radio frequency identification technology (RFID), can solve problems such as high manufacturing costs, environmental pollution, and many processes, and achieve the effects of reducing manufacturing costs, simplifying manufacturing processes, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

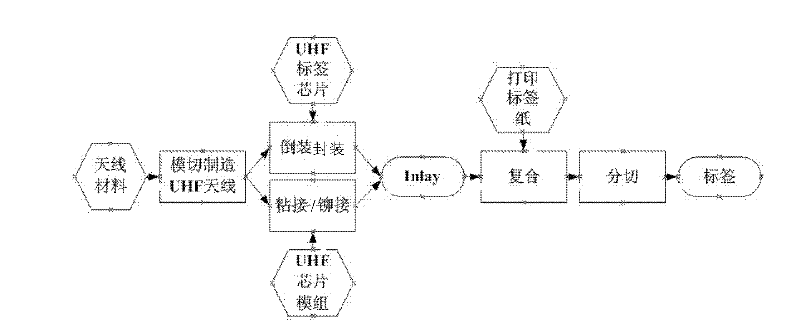

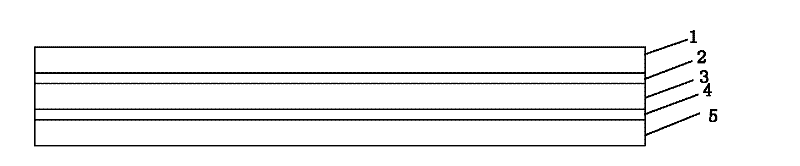

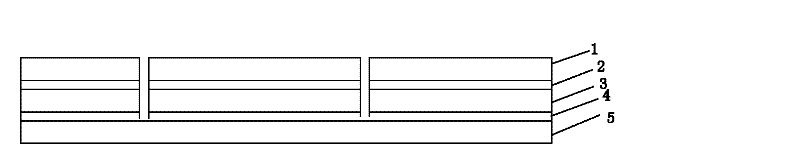

[0046] like figure 1 , figure 2As shown, the UHF RFID antenna is die-cut on the multi-layer structural material with a knife die. The multi-layer structure material is composed of Mylar metal foil layer, self-adhesive layer and release layer. The Mylar metal foil layer can be divided into three layers: conductive layer, adhesive layer and reinforcement layer, and its thickness is not more than 60μm. The release layer is the bottom layer, the self-adhesive layer is on the top of the release layer, the Mylar metal foil layer is on the top of the self-adhesive layer, and the conductive layer is on the top of the Mylar metal foil layer. The adhesive layer connects the conductive layer and the conductive layer. The layers are glued together. The self-adhesive layer is medium-strength or low-strength self-adhesive, located below the Mylar metal foil layer, the coating thickness is not greater than 15μm, the release layer is white silicon paper, cardboard, PVC, PET, PP, located T...

Embodiment 2

[0048] The mechanical knife mold in the first embodiment can also be replaced by a laser with a medium and small power laser source. Half-cut through the layer structure material, even with laser cutting, cut through the Mylar metal foil layer through laser focusing and adjusting laser power, stop at the self-adhesive layer, and the release layer is completely preserved; it can also be fully cut through, even with laser cutting It can penetrate all the film layers; it can also partially cut through, that is, half cut through at the selected position.

[0049] In summary, the technical solution of the present invention adopts the die-cutting method to die-cut the UHF RFID antenna. Compared with the etching method, a large amount of acid and alkali chemicals are no longer used, and the pollution to the environment is avoided. The simplification of the manufacturing process reduces the manufacturing cost of the UHF RFID antenna, thereby reducing the manufacturing cost of the UHF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com