Patterned graphene field emission cathode and preparation method thereof

An emission cathode, patterning technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc. problem, to achieve the effect of low cost, high electron emission current density and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

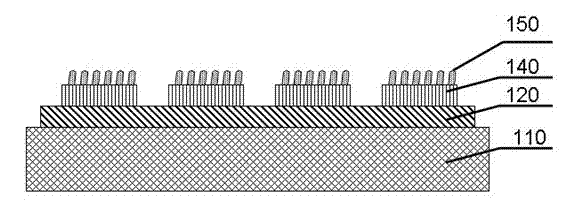

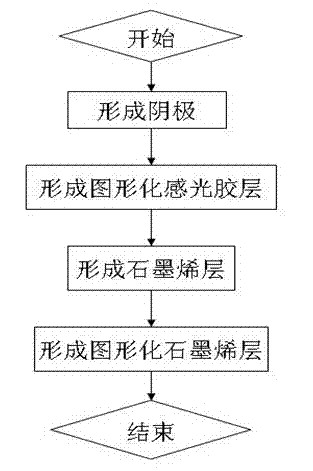

[0029] The preparation process of a patterned graphene field emission cathode is as follows:

[0030] Step 1: Preparation of zinc oxide precursor sol

[0031] Accurately weigh 8.2621g of zinc acetate dihydrate with an electronic balance, and put it into a conical flask filled with about 30mL of isopropanol solvent. Stir with a constant temperature magnetic stirrer and keep the temperature at 70 o C, after 10 minutes, put 4.6mL of ethanolamine stabilizer and stir for 10 minutes. After cooling, titrate with isopropanol in a 50mL volumetric flask. Finally at 70 o After stirring on a constant temperature magnetic stirrer at C for 1 hour, a uniform and transparent sol was formed. After standing still for at least 48 hours, a zinc oxide precursor sol solution is formed.

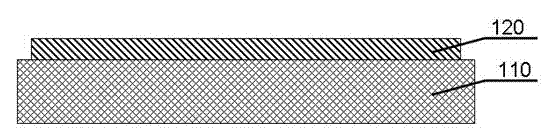

[0032] Step 2: preparation of the glass substrate 110 . Carry out scribing and cleaning on the substrate material of the glass substrate 110 .

[0033] Step 3: Preparation of cathode 120 . Electrode 120 is ...

Embodiment 2

[0044] The preparation process of a patterned graphene field electron emission cathode is the same as that of Embodiment 1, except that the conductive adhesion layer 130 is made of indium oxide doped with tin (ITO). Its step 2, step 3, step 4, step 5, step 6 are identical with embodiment 1, and the preparation of step 1 sol precursor is as follows:

[0045] Weigh a certain amount of indium nitrate pentahydrate crystals, dissolve in acetylacetone, reflux at 60°C for 3 hours, mix tin chloride pentahydrate dissolved in a small amount of absolute alcohol with it (the molar ratio of tin and indium is 1:10 ), to obtain ITO sol.

[0046] The present invention provides a patterned graphene field electron emission cathode, the conductive adhesion layer can be but not limited to zinc oxide film, ITO film, tin oxide film, silicon film, titanium oxide film.

[0047] The invention proposes a patterned graphene field electron emission cathode. Through the introduction of the inorganic con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com