Method for manufacturing lithium ion battery lug

A technology for a lithium ion battery and a manufacturing method, applied in the field of secondary lithium ion batteries, can solve problems such as increasing the internal resistance of battery connection, and achieve the effects of reducing the internal resistance of the connection, reducing the connection links, and improving the rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

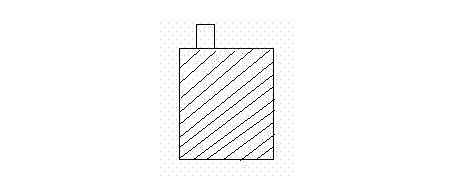

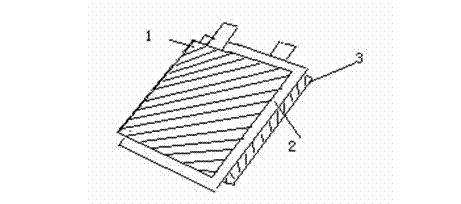

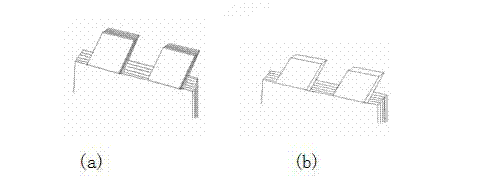

Image

Examples

Embodiment 1

[0024] Take LiFePO 4 Add 85~93 parts of active material powder to the planetary ball mill, add 2~5 parts of Super P conductive agent, 2~5 parts of ks-6 conductive agent, 1~8 parts of binder 1, 0.5~6 parts of binder 2 , 80~120 parts of NMP organic solvent, after being fully mixed in a planetary ball mill, it is made into a uniformly mixed positive electrode slurry. The configured positive electrode slurry is evenly coated on the 15um thick aluminum foil through the gap coating part on the experimental small coating machine, wherein the part coated with the positive electrode slurry is the positive electrode counter electrode part, and the part not coated with the positive electrode slurry Part is the ear part; the aluminum foil is coated with a total of 2um thick nano-carbon pre-coating (both sides) in advance to make a pole piece, and the double-sided dressing of the pole piece, the surface density of the double-sided dressing is 0.02g / cm 2 , Roll the pole piece to 2.1g / cm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com