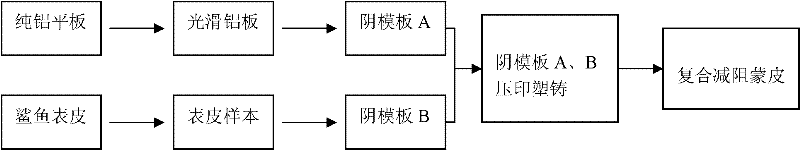

Manufacturing method of complex drag reduction coating with flexible wall and imitation shark skin micro-groove

A production method and shark-like technology, which are applied in the field of bionics, can solve the problems of narrow applicable speed range, poor skin forming quality, low forming efficiency, etc., and achieve low cost, strong practicability and operability, and compound reduction. High resistivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Selection of raw materials: The selected shark is a macaque. The experimental sample of the shark was purchased from Beijing Aquatic Products Company. The initial sample was in a frozen state, with a body length of 1.4m and a weight of 23Kg; 2.5% glutaraldehyde solution, different concentrations of ethanol, Acetone, deionized water, trimethylchlorosilane and other chemical reagents were purchased from Beijing Aoli Chemical Reagent Co., Ltd.; the vacuum drying oven was PZT-6020 intelligent vacuum drying oven produced by Shanghai Yiheng Technology Co., Ltd.

[0061] Step 1: Prepare negative template A6

[0062] (A) Mechanically polish a 2cm-thick pure aluminum plate (purity>99.00%) with sandpaper, and then ultrasonically clean it with acetone, ethanol, and plasma water for 5 minutes;

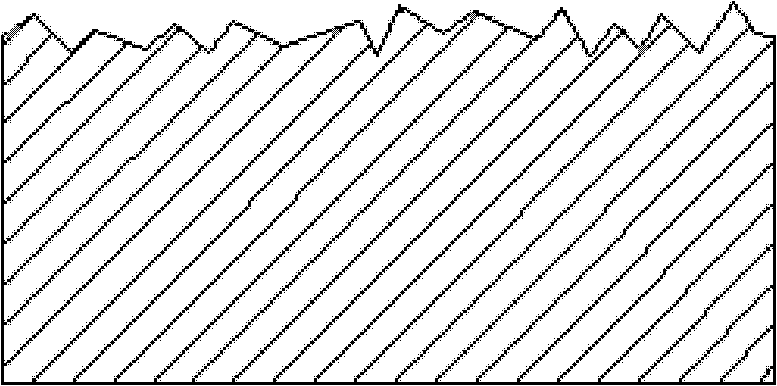

[0063] (B) The aluminum plate obtained in the above step is processed by an EDM high-speed small-hole machine into a group hole array with an inclination of 15°, a hole depth of 1000 μm, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com