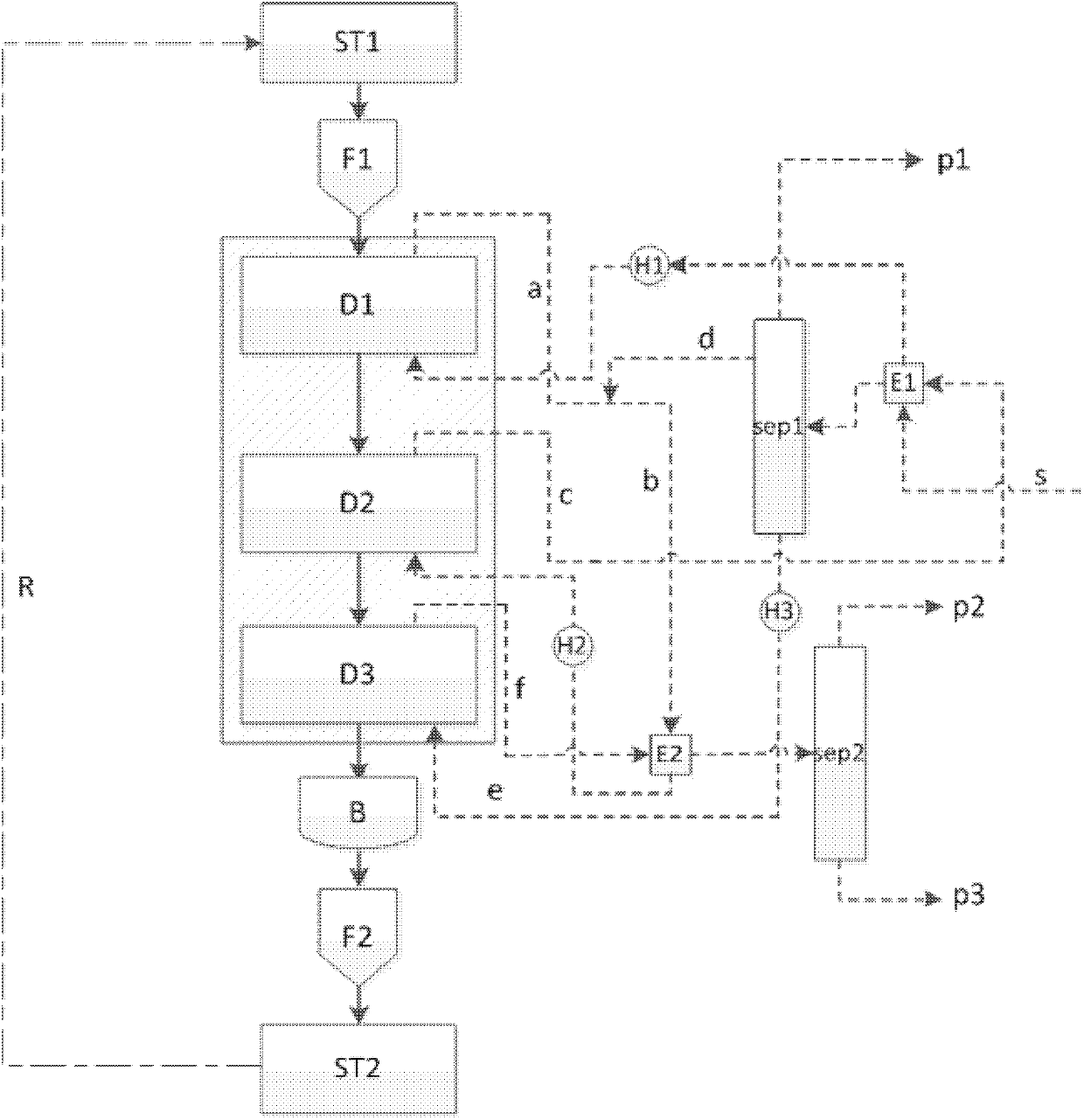

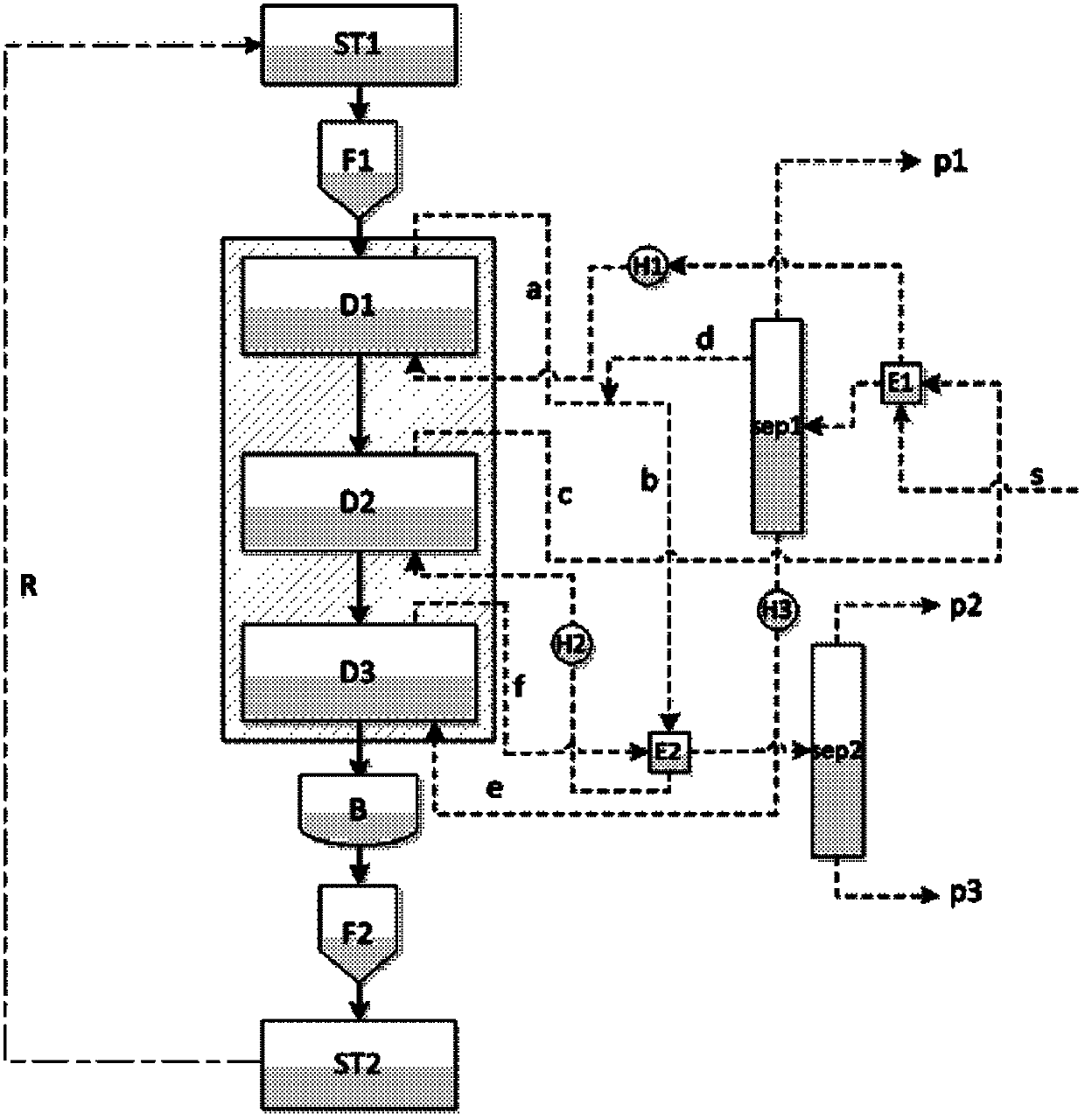

Semi-continuous method for converting methyl alcohol into propylene by using moving bed technology

A methanol conversion and moving bed technology, applied in organic chemistry, chemical recovery, ethylene production, etc., can solve the problems of large transmission power, high energy consumption, poor economic benefits, etc., to increase the reaction system and regeneration device, reaction continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1) The molecular sieve catalyst is mixed with the catalyst diluent and then continuously passed into the first reaction zone. The inlet temperature of the methanol raw material is 240°C. The methanol raw material is passed into the first reaction zone to contact with the molecular sieve catalyst. Under the condition of MPa~0.3MPa, the molecular sieve catalyst stays in the first reaction zone for 30h, and produces the first stream, and the outlet temperature of the first stream is 280°C;

[0069] The first reaction zone is a moving bed reactor;

[0070] 2) The molecular sieve catalyst after passing through the first reaction zone enters the second reaction zone, and the first stream obtained in step 1) is added with utility water vapor and then passed into the second reaction zone to contact with the molecular sieve catalyst, the first stream The molar ratio of stream to water vapor is 1:1, the inlet temperature of the first stream is 450°C, and under the conditions of 4...

Embodiment 2

[0091] 1) The molecular sieve catalyst is mixed with the catalyst diluent and then continuously passed into the first reaction zone. The inlet temperature of the methanol raw material is 260°C. The methanol raw material is passed into the first reaction zone to contact with the molecular sieve catalyst. Under the condition of MPa ~ 0.6MPa, the molecular sieve catalyst stays in the first reaction zone for 50 hours to generate the first stream, and the outlet temperature of the first stream is 300°C;

[0092] The first reaction zone is a moving bed reactor;

[0093]2) The molecular sieve catalyst after passing through the first reaction zone enters the second reaction zone, and the first stream obtained in step 1) is added with utility water vapor and then passed into the second reaction zone to contact with the molecular sieve catalyst, the first stream The molar ratio of stream to water vapor is 4:1, the inlet temperature of the first stream is 470°C, and under the conditions ...

Embodiment 3

[0114] 1) The molecular sieve catalyst is mixed with the catalyst diluent and then continuously passed into the first reaction zone. The inlet temperature of the methanol raw material is 280°C. The methanol raw material is passed into the first reaction zone to contact with the molecular sieve catalyst. Under the condition of MPa~1MPa, the molecular sieve catalyst stays in the first reaction zone for 100h to generate the first stream, and the outlet temperature of the first stream is 320°C;

[0115] The first reaction zone is a moving bed reactor;

[0116] 2) The molecular sieve catalyst after passing through the first reaction zone enters the second reaction zone, and the first stream obtained in step 1) is added with utility water vapor and then passed into the second reaction zone to contact with the molecular sieve catalyst, the first stream The molar ratio of stream to water vapor is 1:4, the inlet temperature of the first stream is 480°C, and under the conditions of 480°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com