Clean tanning hair removal expansion method

A clean and preparation technology, applied in the field of clean tanning, hair removal and expansion, can solve the problems of large enzyme dosage, high temperature and long time, and achieve the effect of simple operation, good elasticity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

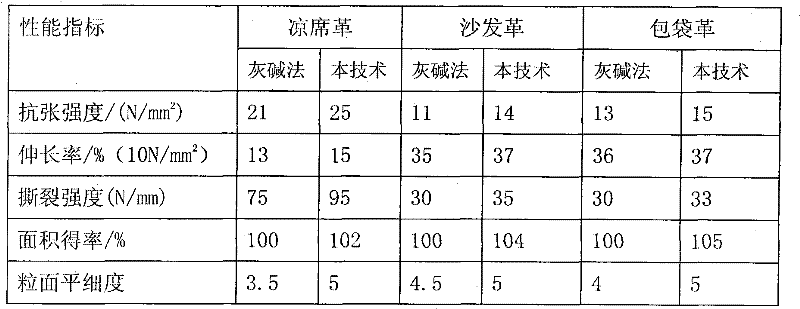

[0022] Embodiment 1: buffalo mat leather process

[0023] (1) Soak in water Put 100 parts of salted skin into the drum, add 150 parts of water, rotate for 60 minutes, drain, add 200 parts of water, adjust the temperature to 30°C, add 0.3 part of penetrant JFC, 0.5 part of Desaijing DF, 0.2 part of soda ash , 0.2 parts of Desaibei DB, 0.1 parts of Desaijing KL, turn for 60 minutes, stop for 60 minutes; turn for 5 minutes, stop for 50 minutes, a total of 10 times, add mixed enzyme preparation 20 activity units / gram skin, diisopropanol 0.4 parts of amine, 0.3 parts of triisopropanolamine, turn for 30 minutes, stop for 60 minutes; then turn for 5 minutes per hour, a total of 10 times, control the water, wash out the drum; remove the flesh and hair;

[0024] (2) Alkali expansion Put the above-mentioned de-fleshed and hair-removed skin into the drum, add 30 parts of water, add 0.2 parts of sodium sulfide, 0.3 parts of sodium hydrogen sulfide, 0.4 parts of NaOH, 0.5 parts of lime pow...

Embodiment 2

[0025] Example 2: Yellow cow sofa and bag leather process

[0026] (1) Put 100 parts of soaked salt skin into the drum, add 180 parts of water, rotate for 30 minutes, drain, add 250 parts of water, adjust the temperature to 25 ° C, add 0.2 parts of penetrant JFC, 0.3 parts of Dawei Lite DG-A, 0.4 parts of soda ash 0.4 parts of Desabei DB, 0.4 parts of Dawei Lite MT, turn for 45 minutes, stop for 60 minutes; turn for 1 minute, stop for 55 minutes, a total of 6 times, add mixed enzyme preparation 30 activity units / gpi, diisopropyl 0.1 part of alcoholamine, 0.5 part of triisopropanolamine, turn for 30 minutes, stop for 60 minutes; then turn for 2 minutes per hour, a total of 6 times, control the water, wash the drum, remove the flesh and hair;

[0027] (2) Alkali expansion Put the above-mentioned fleshed and dehaired skin into the drum, add 50 parts of water, control the temperature at 18°C, add 0.3 parts of sodium hydrosulfide, 0.2 parts of NaOH, 2.0 parts of lime powder, 1.0 pa...

Embodiment 3

[0028] Embodiment 3: buffalo outfit leather technology

[0029] (1) Put 100 parts of soaked salted leather into the drum, add 200 parts of water, rotate for 50 minutes, drain, add 230 parts of water, adjust the temperature to 20 °C, add 0.1 part of penetrant JFC, 0.2 part of DG-B, 0.3 part of soda ash 0.35 parts of Daweizimu SD, 0.3 parts of Dawei Lite FMN, turn for 50 minutes, stop for 60 minutes; turn for 2 minutes, stop for 50 minutes, a total of 8 times, add mixed enzyme preparation 60 activity units / gram skin, 0.3 parts of propanolamine, turn on for 60 minutes, stop for 60 minutes, then turn for 1 minute per hour, a total of 4 times, control the water, wash out the drum, remove the flesh and hair;

[0030] (2) Alkali expansion Put the above-mentioned skin after de-fleshing and hair removal into the drum, add 45 parts of water, add 0.3 parts of NaOH, 1.5 parts of lime powder, 1.2 parts of Desaijing POU, add 170 parts of water, and rotate for 40 minutes. NaOH 0.7 part, Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com