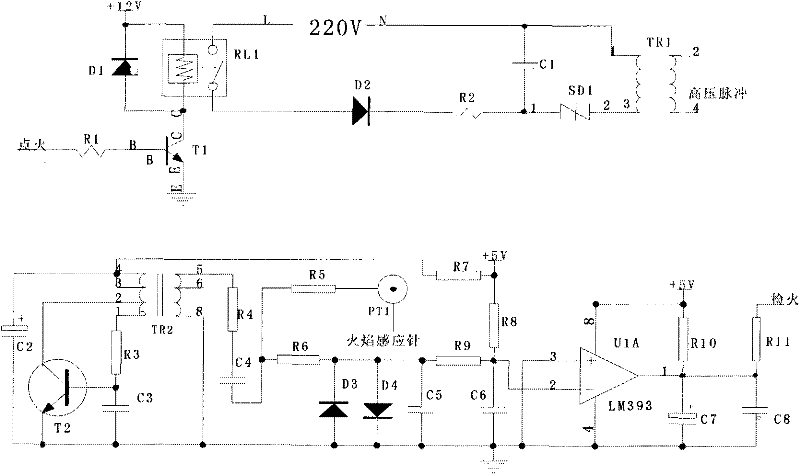

Flame ion current intensity detection and pulse ignition circuit

A flame ion and current size technology, applied in the measurement of current/voltage, ignition by spark, combustion ignition, etc., can solve the problems of high cost, increased cost of LC oscillator booster, poor reliability of LC oscillator booster, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

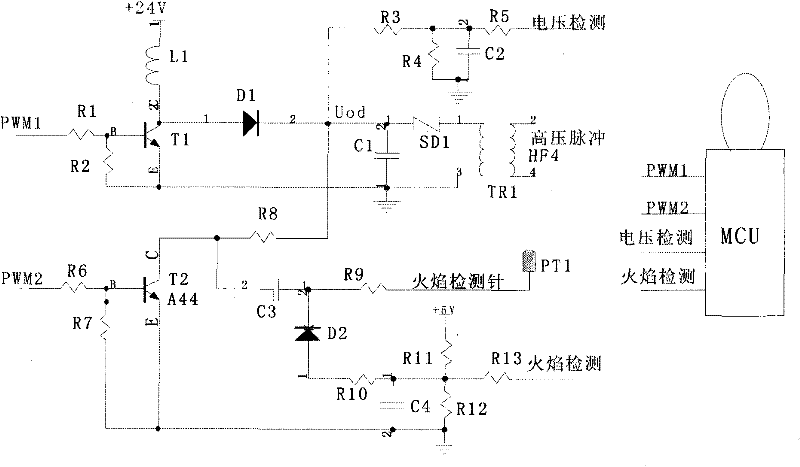

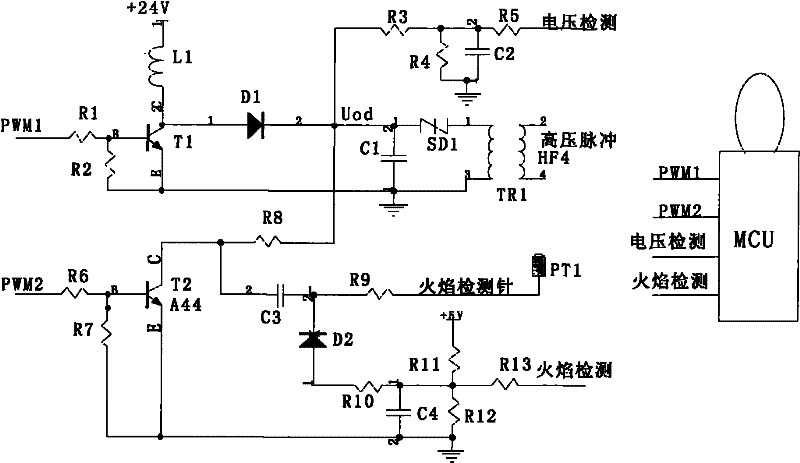

[0019] The flame ion current detection and pulse ignition circuit of the present invention will be further described in detail below in conjunction with the embodiment, the circuit schematic diagram is as follows figure 2 shown.

[0020] The selected values of each component are: the resistance value of R1 is 4K7 ohms, the resistance value of R2 is 1K ohms, the resistance value of R3, R9, R11 is 1M ohms, the resistance value of R4 is 20K ohms, and the resistance value of R5, R6, R7, R13 10K ohms, R8 resistance is 200K ohms, R10 resistance is 470K ohms, R12 resistance is 4M7 ohms; C1 model is 1μF / 250V, C2 model is 103 / 50V, C3 model is 103 / 400V, C4 model is 104 / 50V; L1 model is 33mH; D1, D2 model is FR107; SD1 model is K2000G; T1, T2 model is A44; TR1 model is HF4.

[0021] The PWM1, R1, R2, T1, L1, D1, and C1 of the MCU form a boost circuit. When the output of PWM1 is high: T1 is saturated and turned on, and L1 is energized to store energy. When the output of PWM1 is low:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com