7 split conductor with cable copper core section of 3500mm<2> and manufacturing method thereof

A technology for dividing conductors and cross-sections is used in medium and high voltage fire-resistant cables, cable copper core cross-sections, 7-split conductors and their preparation processes, and special medium and high voltage fire-resistant cables. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

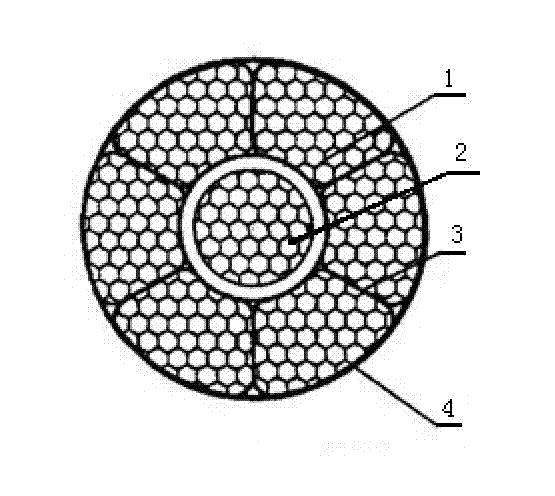

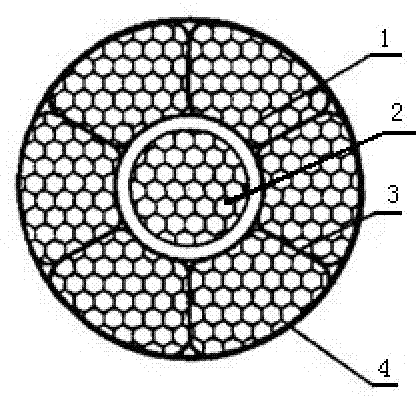

[0030] A cable copper core section 3500mm 2 The 7-split conductor includes a conductor composed of six split strands 1 of the same cross-section and a central stranding unit 2, and a corrugated insulating paper 3 is arranged between the six split strands 1 and the central stranding unit 2 The split strands 1 are combined and twisted leftward around the central twisting unit 2 to form a cable, and the outer circumference of the conductor is wrapped with a semi-conductive nylon tape 4 in turn.

[0031] In the present invention, the section of the central stranding unit 2 is 110mm 2 , the section of split strand 1 is 560 mm 2 ; The radian of the split strand 1 is 50 degrees; the section of the split strand 1 is fan-shaped.

[0032] When the present invention is in use, 91 disks and 630 frame stranding machine equipment are used to twist the central stranding unit 2 with copper monofilament; through the frame stranding equipment, the pre-screw pressing wheel is used to strand a ...

Embodiment 2

[0036] A cable copper core section 3500mm 2 The 7-split conductor includes a conductor composed of six split strands 1 of the same cross-section and a central stranding unit 2, and a corrugated insulating paper 3 is arranged between the six split strands 1 and the central stranding unit 2 The split strands 1 are combined and twisted leftward around the central twisting unit 2 to form a cable, and the outer circumference of the conductor is wrapped with a semi-conductive nylon tape 4 in turn.

[0037] In the present invention, the section of the central stranding unit 2 is 115mm 2, the section of split strand 1 is 565 mm 2 ; The radian of the split strand block 1 is 60 degrees; the section of the split strand block 1 is fan-shaped.

[0038] When the present invention is in use, the central stranding unit 2 conductor pay-off reels are placed on the 1600mm rotating pay-off frame, and the six fan-shaped segmented block 1 conductor pay-off reels are placed on the 2240mm rotary pa...

Embodiment 3

[0040] A cable copper core section 3500mm 2 The 7-split conductor includes a conductor composed of six split strands 1 of the same cross-section and a central stranding unit 2, and a corrugated insulating paper 3 is arranged between the six split strands 1 and the central stranding unit 2 The split strands 1 are combined and twisted leftward around the central twisting unit 2 to form a cable, and the outer circumference of the conductor is wrapped with a semi-conductive nylon tape 4 in turn.

[0041] In the present invention, the section of the central stranding unit 2 is 120mm 2 , the section of split strand 1 is 570 mm 2 ; The radian of the split strand block 1 is 70 degrees; the section of the split strand block 1 is fan-shaped.

[0042] When the present invention is in use, the central stranding unit 2 conductor pay-off reels are placed on the 1650mm rotating pay-off frame, and the six fan-shaped segmented block 1 conductor pay-off reels are placed on the 2280mm rotary p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com