Split type ion source extraction electrode system

A technology for extracting electrodes and ion sources, applied to circuits, discharge tubes, electrical components, etc., can solve the problems of thermal deformation and displacement of the electrode system, affecting the extraction beam current and beam quality, and difficulty in adapting to various beam currents, etc., to achieve Save equipment investment, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

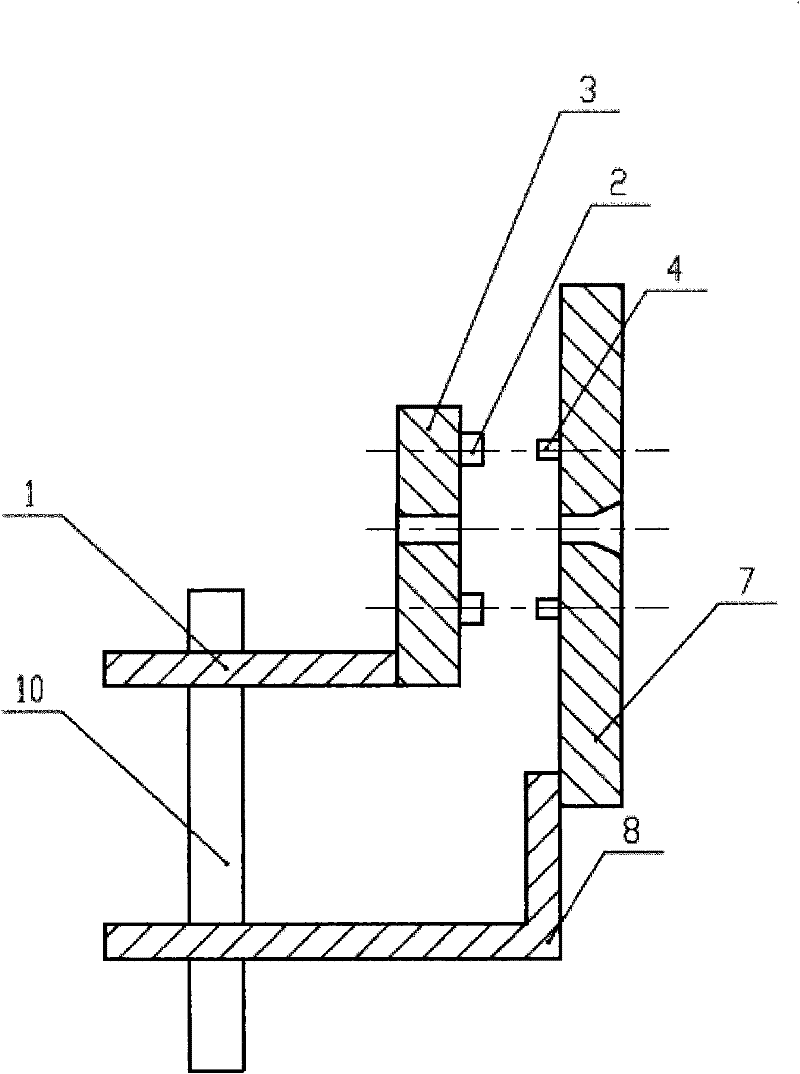

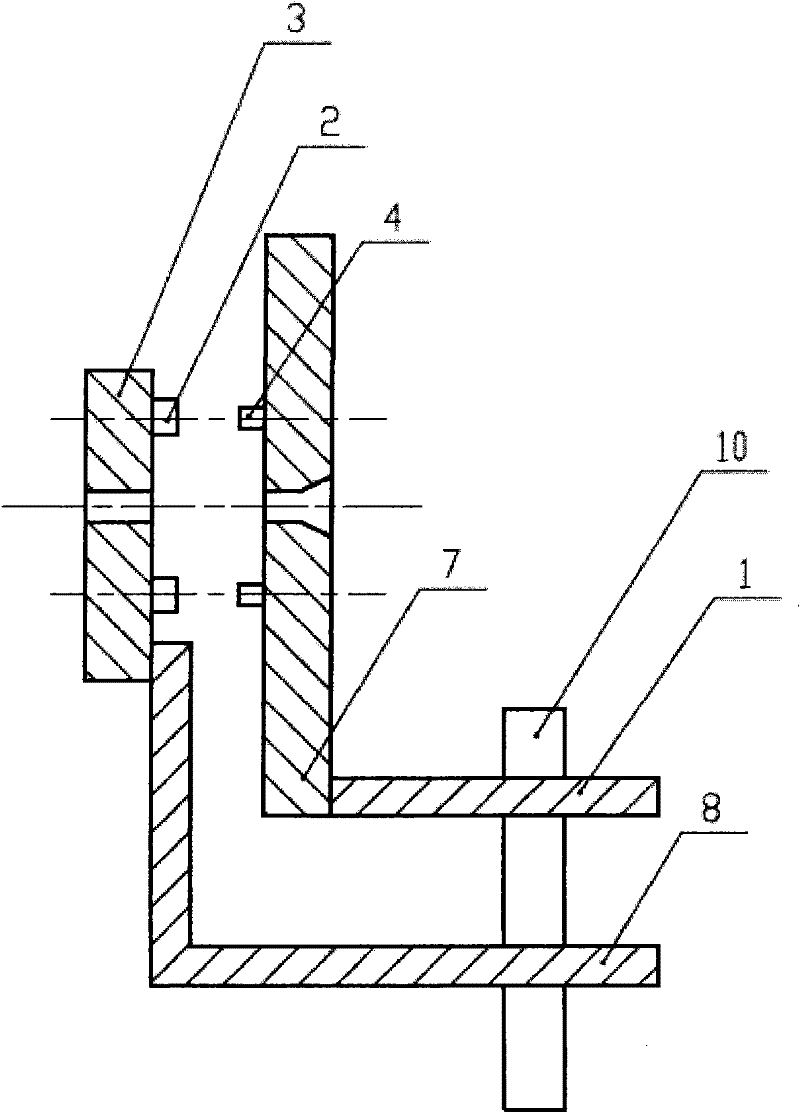

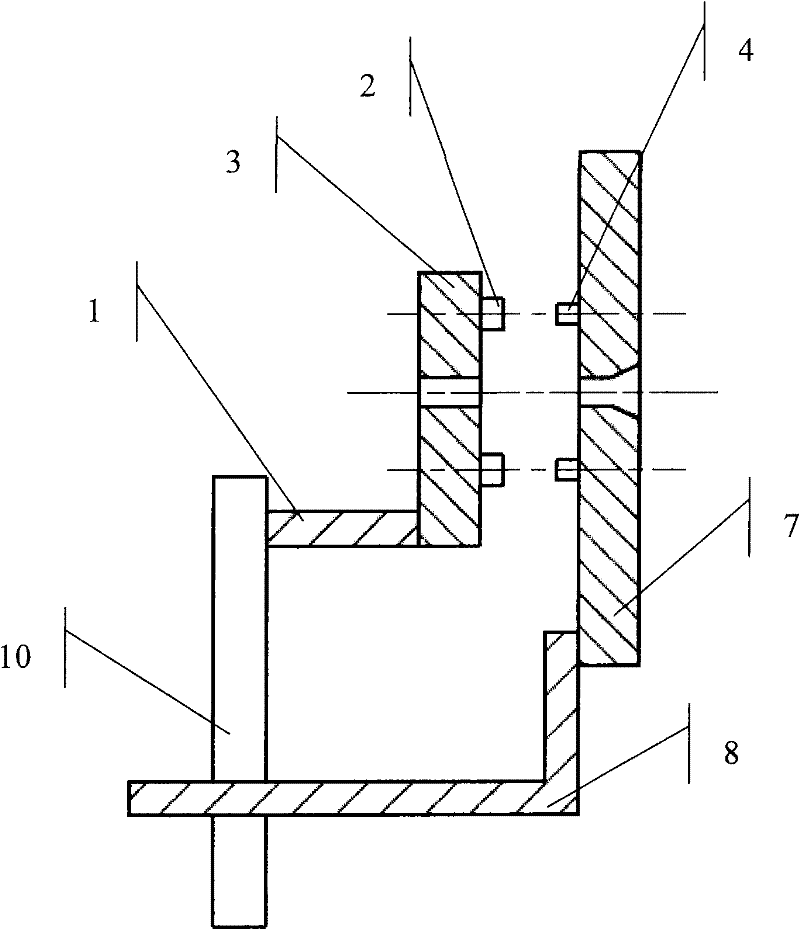

[0029] The present invention will be further introduced below with reference to the specific embodiments of the accompanying drawings. It should be understood that these descriptions are illustrative and the present invention is not limited thereto. The scope of the present invention is limited only by the scope of the appended claims.

[0030] first reference Figure 6 , to introduce the arrangement and working principle of the key components of the ion implanter.

[0031] Such as Figure 6 As shown, the ion source extraction electrode (not shown) extracts the ion beam generated in the ion source. In order to select the desired ion species from the total ion beam, so as to ensure the provision of ion species with a certain charge and mass number, such as boron (B), phosphorus (P), arsenic (As), argon (Ar), the ion beam Passes through a specialized ion sorting component - the mass analyzer. Then the ion beam passes through two sets of magnetic quadrupole lenses, which stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com