Ge-Sb-Te Ge-enriched N-doped phase-change material for phase-change memory and preparation method thereof

A phase change memory, ge-sb-te technology, applied in electrical components and other directions, can solve the problems of low crystallization temperature and low crystalline resistivity, and achieve high crystallization temperature, grain refinement, and improved data retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. The Ge-Sb-Te rich Ge-doped N thin film material was prepared on the silicon substrate and the thermally oxidized silicon substrate at the same time by magnetron sputtering two-target co-sputtering method, and the background vacuum degree was 1.6×10 -4 Pa, the argon gas pressure during sputtering is 0.22Pa, N 2 / Ar 2 The flow ratio is 1sccm / 49sccm, Ge target and Ge 2 Sb 2 Te 5 The sputtering power of the target is 20W for radio frequency and 30W for DC respectively, the sputtering rate is 10nm / min, and the sputtering time is 30min. The thickness of the prepared phase change film is 300nm observed by SEM, and the mole percentage of N element is 2.02 by XPS. %, EDS energy spectrum analysis shows that the composition of the material is N 2.02 (Ge 3 Sb 2 Te 5 ) 97.98 .

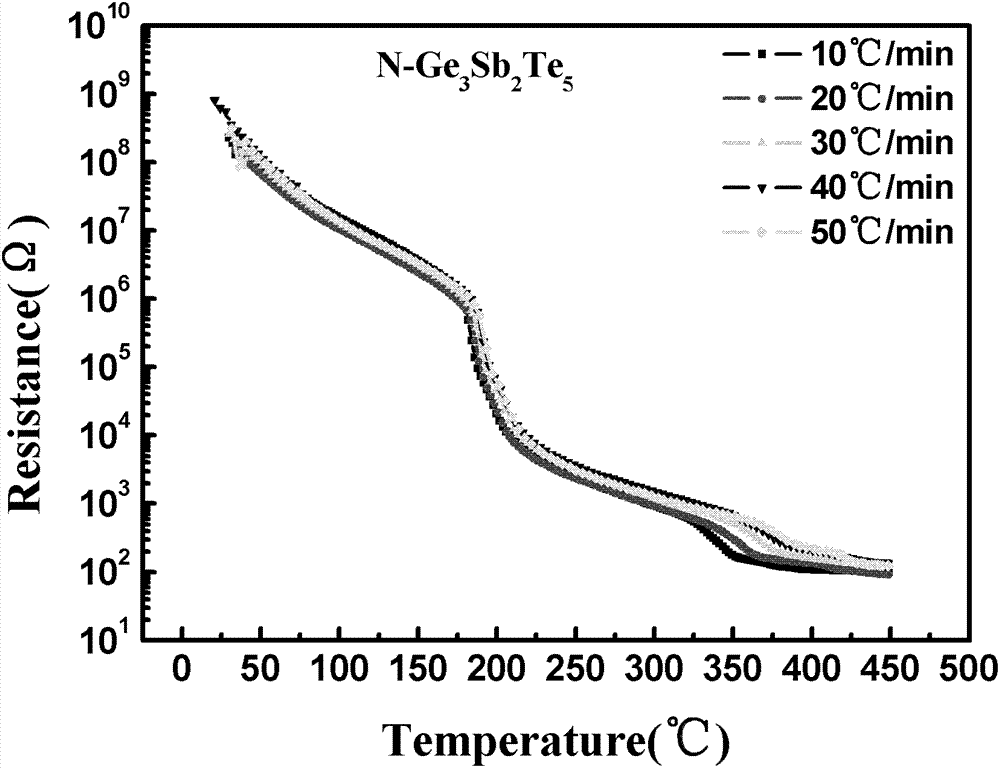

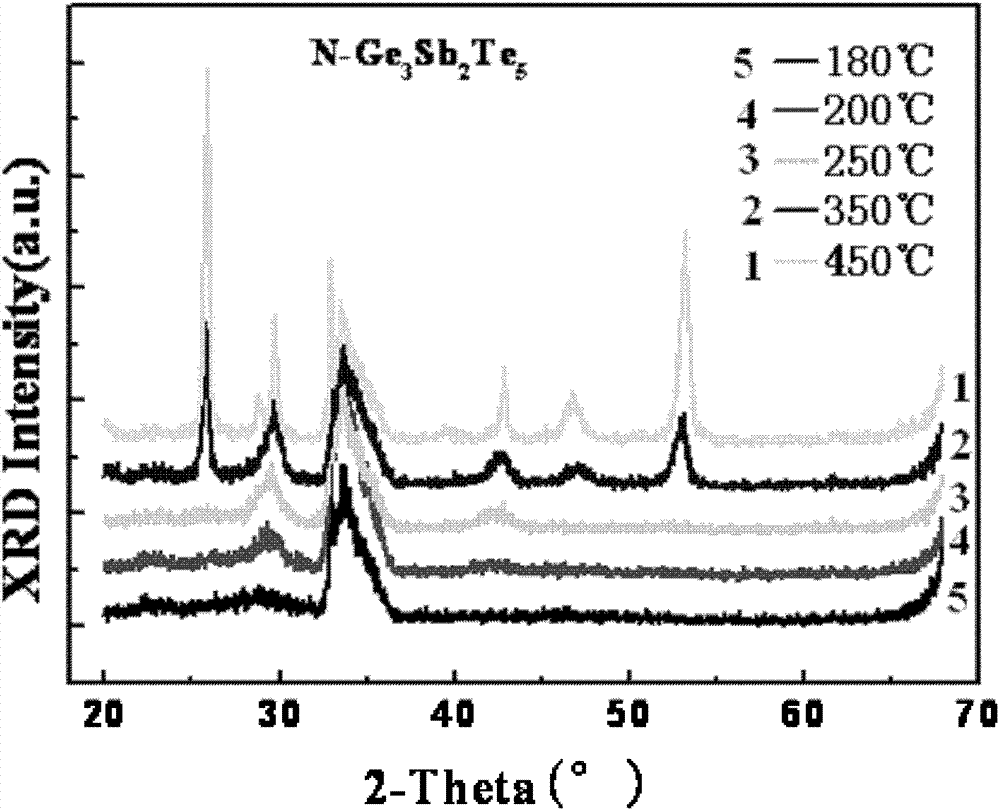

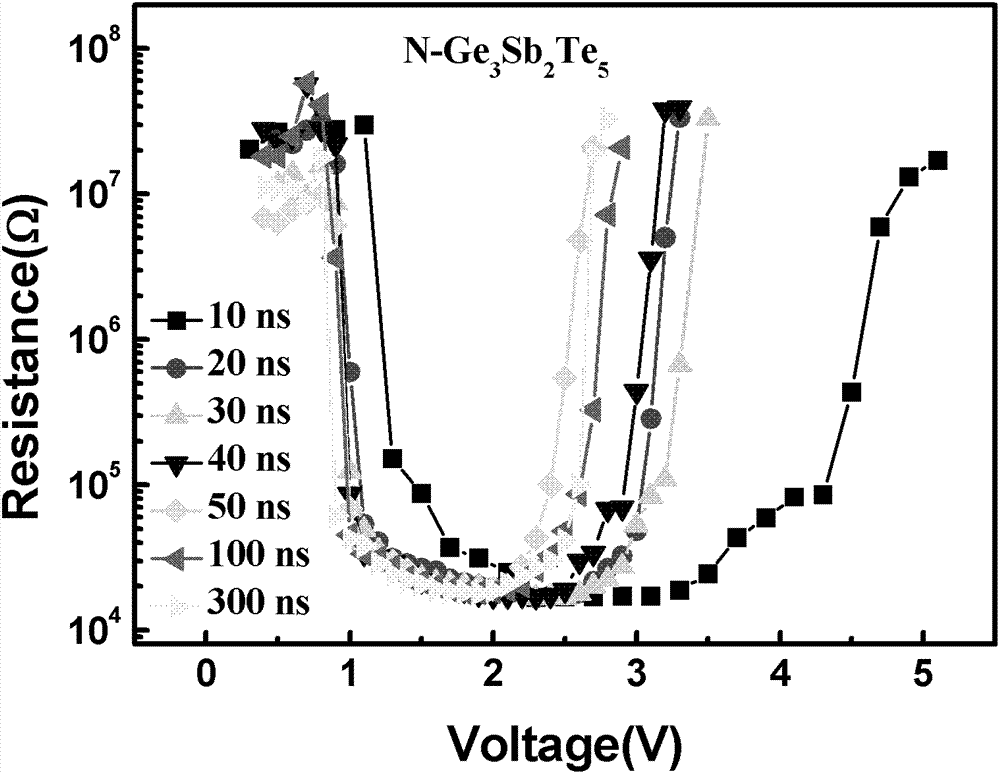

[0032] 2. The obtained N grown on the silicon oxide wafer without annealing 2.02 (Ge 3 Sb 2 Te 5 ) 97.98 The in-situ resistance test of the phase-change thin film material shows the relation...

Embodiment 2

[0036] 1. Prepare Ge-Sb-Te rich Ge-doped N film material N according to the magnetron sputtering method of embodiment 1 10 [(Ge 3 Te)(Sb 2 Te 3 ) 2 ] 90 : When using magnetron sputtering two-target co-sputtering method to sputter on silicon substrate and thermally oxidized silicon substrate at the same time, by adjusting N 2 / Ar 2 Flow ratio and Ge target and Ge 2 Sb 2 Te 5 The sputtering power of the target is obtained.

[0037] N in this example 10 [(Ge 3 Te)(Sb 2 Te 3 ) 2 ] 90 The thickness of the phase change film material is 300nm observed by SEM, the content of N element is 10% obtained by XPS, and the EDS energy spectrum analysis shows that the composition of the material is N 10 [(Ge 3 Te)(Sb 2 Te 3 ) 2 ] 90 .

[0038] 2. The N that was grown on the silicon oxide sheet and not annealed obtained in this embodiment 10 [(Ge 3 Te)(Sb 2 Te 3 ) 2 ] 90 The in-situ resistance test of the phase change thin film material, the relationship between the s...

Embodiment 3

[0042] 1. Prepare Ge-Sb-Te rich Ge-doped N film material N according to the magnetron sputtering method of embodiment 1 25 [(Ge 3 Te)(Sb 2 Te 3 )] 75 : When using magnetron sputtering two-target co-sputtering method to sputter on silicon substrate and thermally oxidized silicon substrate at the same time, by adjusting N 2 / Ar 2 Flow ratio and Ge target and Ge 2 Sb 2 Te 5 The sputtering power of the target is obtained.

[0043] N in this example 25 [(Ge 3 Te)(Sb 2 Te 3 )] 75 The thickness of the phase change film material is 300nm observed by SEM, the content of N element is 10% obtained by XPS, and the EDS energy spectrum analysis shows that the composition of the material is N 25 [(Ge 3 Te)(Sb 2 Te 3 )] 75 .

[0044] 2. The N that was grown on the silicon oxide sheet and not annealed obtained in this embodiment 25 [(Ge 3 Te)(Sb 2 Te 3 )] 75 The in-situ resistance test of the phase change thin film material, the relationship between the sheet resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com