Large-capacity lithium ion battery cathode and preparation method thereof

A lithium-ion battery, high-capacity technology, applied in the field of electrochemistry, can solve the problems of decreased electrochemical cycle stability, material structure damage, electrode deformation, etc., and achieves good charge-discharge cycle reversibility, no electrode deformation, and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

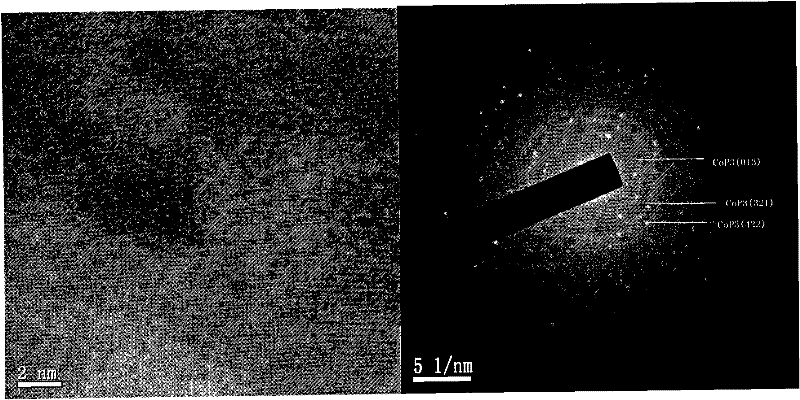

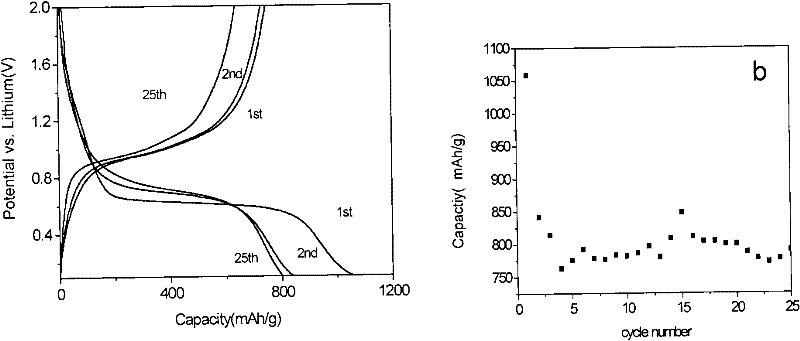

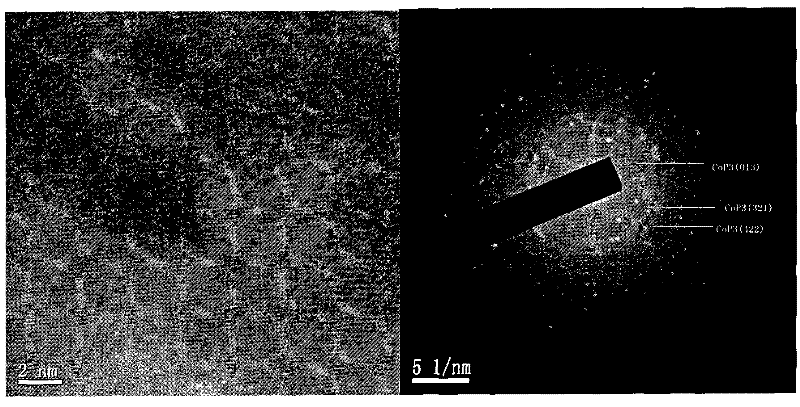

[0016] Embodiment: a kind of negative electrode of lithium ion battery comprises the negative electrode film of electrode substrate, substrate surface, and the negative electrode film of its substrate surface is cobalt phosphide (CoP 3 ) film, the substrate is a stainless steel sheet, and the thickness of the cobalt phosphide film is 0.2-1 μm.

[0017] Its preparation method is:

[0018] a. Metal cobalt powder is mixed with red phosphorus powder, and the mixing ratio is that metal cobalt is 1: 2 (molar ratio) than red phosphorus powder, mixes evenly and grinds, and tabletting is made into the used target of pulse laser deposition;

[0019] b. Put the target and the substrate into the vacuum deposition chamber, the distance between the target and the substrate is 25-50mm, the working gas is argon atmosphere, and the substrate temperature is 500-700°C;

[0020] c. The 1064nm fundamental frequency generated by the neodymium-doped yttrium aluminum garnet laser is tripled to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com