Ultrasonic negative pressure circulating extraction device

A cyclic extraction and negative pressure technology, applied in the field of extraction equipment for active ingredients of natural products, can solve the problems of large amount of solvent, accelerated leaching and extraction, and extraction of heat-sensitive components, etc. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

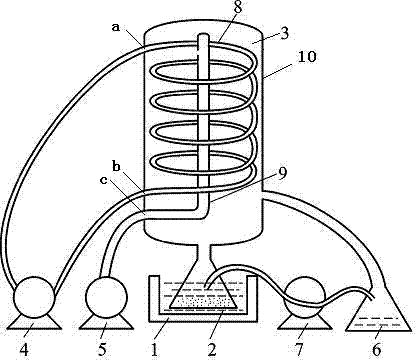

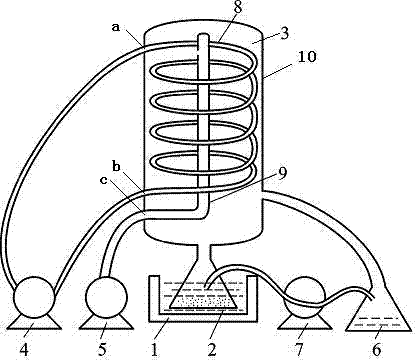

[0012] as attached figure 1 As shown, the extraction bottle 2 containing the feed liquid is placed in the ultrasonic generator 1. Under the action of ultrasound, the active components in the material are efficiently extracted by the extraction solvent, and the extraction temperature and ultrasonic power can be controlled. At the same time, the infusion The pump 7 transports the extract to the collection bottle 6 at a controllable speed. The collection bottle 6 is connected to the reflux evaporator 3. Under the action of the vacuum pump 5, the reflux evaporator 3 is in a negative pressure state. The solvent will evaporate into the reflux evaporator 3, and the low-temperature coolant circulating pump 4 connected to the condensing pipe 8 of the reflux evaporator 3 can keep it at a certain low temperature state. When the solvent vapor diffuses to the surface of the condensing pipe 8, it will condense rapidly It is a liquid solvent, and the fresh solvent will drip into the extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com