Preparation method of medicine intermediate di-cyclopropyl methylamine

A technology of dicyclopropylmethylamine and dicyclopropyl ketone, which is applied in the field of preparation of pharmaceutical intermediates, can solve the problems of low total reaction yield, difficult operation of the reaction, long reaction route, etc., and achieve safe process operation and short reaction steps Less, the effect of improving the total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

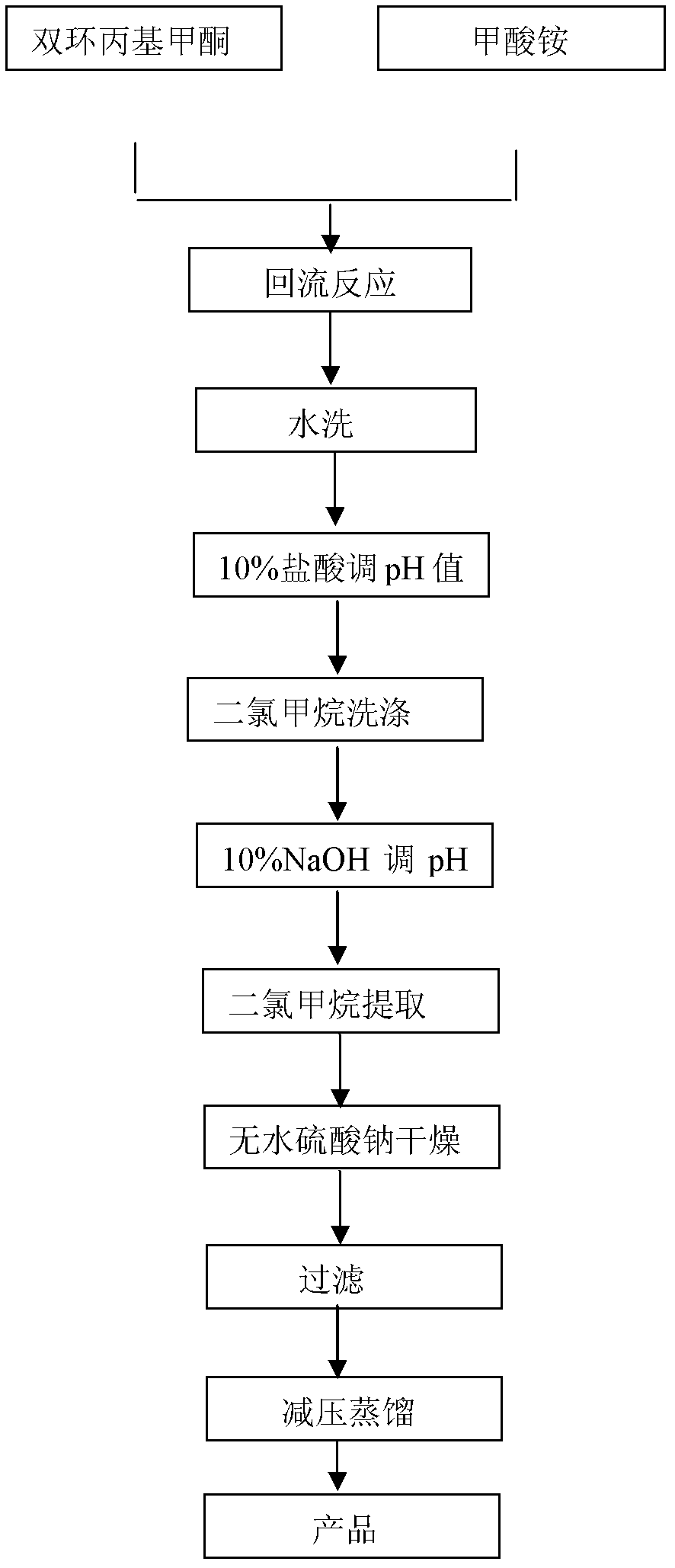

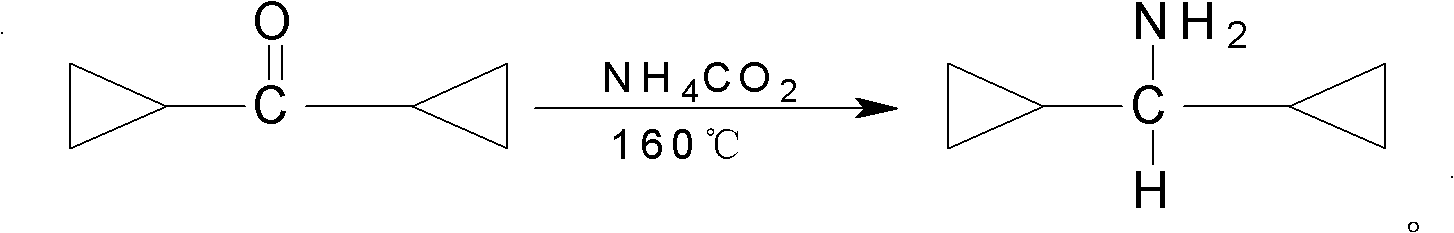

[0020] Weigh 55g of dicyclopropyl ketone and add it to a 500mL three-neck flask connected with a condensation and water separation device, add 62g of ammonium formate under slow stirring, slowly raise the temperature to an oil bath temperature of 170°C, and continuously separate water during the reaction process and remove the upper layer Return the organic phase to the three-necked flask to continue the reflux reaction. After 5 hours of reflux reaction, the reflux temperature in the reaction bottle reaches 160-170°C and no longer rises. Reflux at this temperature for 10 hours. After the reaction, cool to room temperature and wash the reaction mixture with water. 3 times, the amount of water for washing is 30mL each time, the organic phase is separated, and 10% hydrochloric acid is added to adjust the pH value to 4-5, and then washed three times with dichloromethane, the amount of dichloromethane for washing is 40mL each time, after washing Adjust the pH value to 10 with 10% so...

Embodiment 2

[0025] Weigh 110g of dicyclopropyl ketone into a 500mL three-neck flask connected with a condensation and water separation device, and add 184g of ammonium formate while stirring slowly. Slowly heat up to the temperature of the oil bath at 170°C. During the reaction process, water is continuously separated and the upper organic phase is returned to the three-necked flask to continue the reflux reaction. After 5 hours of reflux reaction, the reflux temperature in the reaction bottle reaches 160-170°C and no longer rises. Reflux at temperature for 10 hours. Cool to room temperature after the reaction, wash the reaction mixture 3 times with water, the amount of water used for washing is 40mL each time, separate the organic phase, add 10% hydrochloric acid to adjust the pH value to 4-5, wash with dichloromethane three times, and wash The amount of dichloromethane used is 60mL each time, and the aqueous solution after washing is adjusted to a pH value of 10 with 10% sodium hydroxid...

Embodiment 3

[0030] Weigh 220g of dicyclopropyl ketone into a 1000mL three-neck flask connected with a condensation and water separation device, and add 244g of ammonium formate under slow stirring. Slowly heat up to the temperature of the oil bath at 170°C. During the reaction process, water is continuously separated and the upper organic phase is returned to the three-necked flask to continue the reflux reaction. After 5 hours of reflux reaction, the reflux temperature in the reaction bottle reaches 160-170°C and no longer rises. Reflux at temperature for 10 hours. Cool to room temperature after the reaction, wash the reaction mixture 3 times with water, the amount of water used for washing is 80mL each time, separate the organic phase, add 10% hydrochloric acid to adjust the pH value to 4-5, wash with dichloromethane three times, wash The amount of dichloromethane used is 120mL each time, and the pH value of the washed aqueous solution is adjusted to 10 with 10% sodium hydroxide solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com