Extraction method of morphine from opium

An extraction method and opium technology, applied in the field of pharmaceutical preparations, can solve the problems of complex morphine steps, low extraction yield, and use of toxic organic solvents, and achieve the effects of shortening extraction time, improving extraction efficiency, and facilitating industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

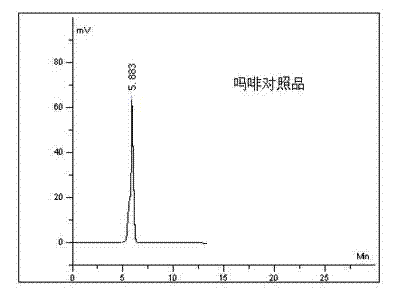

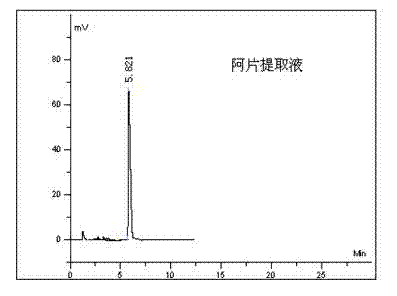

[0049] Example 1 Morphine was extracted from opium with aqueous ethanol.

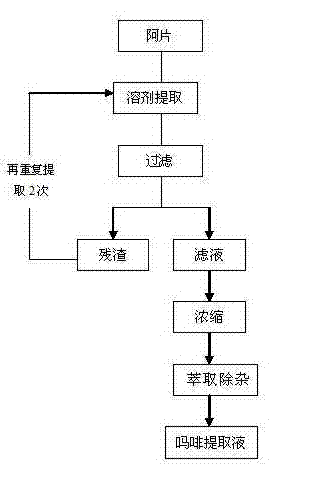

[0050] Include the following process steps in turn:

[0051] (1) Use ethanol aqueous solution with an opium weight-to-volume ratio of 10-20 times as the extraction solvent, with a solvent concentration of 40%-60%; heat and reflux extraction for 3 times; each extraction takes 30-60 minutes.

[0052] (2) Concentrate the three extracts obtained in (1) until the morphine content is 1-3%.

[0053] (3) Add 1-2 times the weight of opium to the concentrated solution obtained in (2) with molten solid paraffin, stir evenly, cover and let stand, discard the upper layer of solid paraffin to obtain a purified morphine solution. The morphine content was determined by HPLC, and the morphine yield was calculated.

[0054] The details and results are shown in Table 1.

[0055] Table 1 Ethanol aqueous solution extraction

[0056] serial number Solvent concentration (%) Solvent consumption (weight ...

Embodiment 2

[0058] Example 2 Pure water extraction.

[0059] (1) Use pure water to extract, the dosage is 10-20 times the opium weight, and use 60-100°C to extract 3 times, 30-60min / time.

[0060] (2) Concentrate the three extracts obtained in (1) until the morphine content is 1-3%.

[0061] (3) Add 1-2 times the weight of opium to the concentrated solution obtained in (2) with molten solid paraffin, stir evenly, cover and let stand, discard the upper layer of solid paraffin to obtain a purified morphine solution.

[0062] The details and results are shown in Table 2. The morphine content was determined by HPLC, and the morphine yield was calculated.

[0063] Table 2 Pure water extraction

[0064] serial number Solvent consumption (weight to volume ratio of opium) temperature (°C) time (minutes) yield 1 10 times 60℃ 30min / time 86.03% 2 15 times 80℃ 45min / time 93.28% 3 20 times 100℃ 60min / time 96.05%

[0065] The res...

Embodiment 3

[0066] Example 3 Dilute hydrochloric acid solution (pH=4) for extraction.

[0067] (1) Extract with dilute hydrochloric acid solution with a pH of 4, the dosage is 10-20 times the opium weight, and extract 3 times at 60-100°C, 30min-60min / time.

[0068] (2) Concentrate the three extracts obtained in (1) until the morphine content is 1-3%.

[0069] (3) Add 1-2 times the weight of opium to the concentrated solution obtained in (2) with molten solid paraffin, stir evenly, cover and let stand, discard the upper layer of solid paraffin to obtain a purified morphine solution.

[0070] The details and results are shown in Table 3. The morphine content was determined by HPLC, and the morphine yield was calculated.

[0071] Table 3 pH is 4 dilute hydrochloric acid solution extraction

[0072] serial number Solvent consumption (weight to volume ratio of opium) temperature (°C) time (minutes) yield 1 10 times 60℃ 30min / time 84.25% 2 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com