Pressure-sensitive adhesive for polaroid

A pressure-sensitive adhesive and polarizer technology, which is applied in the direction of adhesive types, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of pressure-sensitive adhesive adhesive performance reduction, pressure-sensitive adhesive transparency reduction, etc. Achieve the effect of excellent compatibility and excellent optical transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

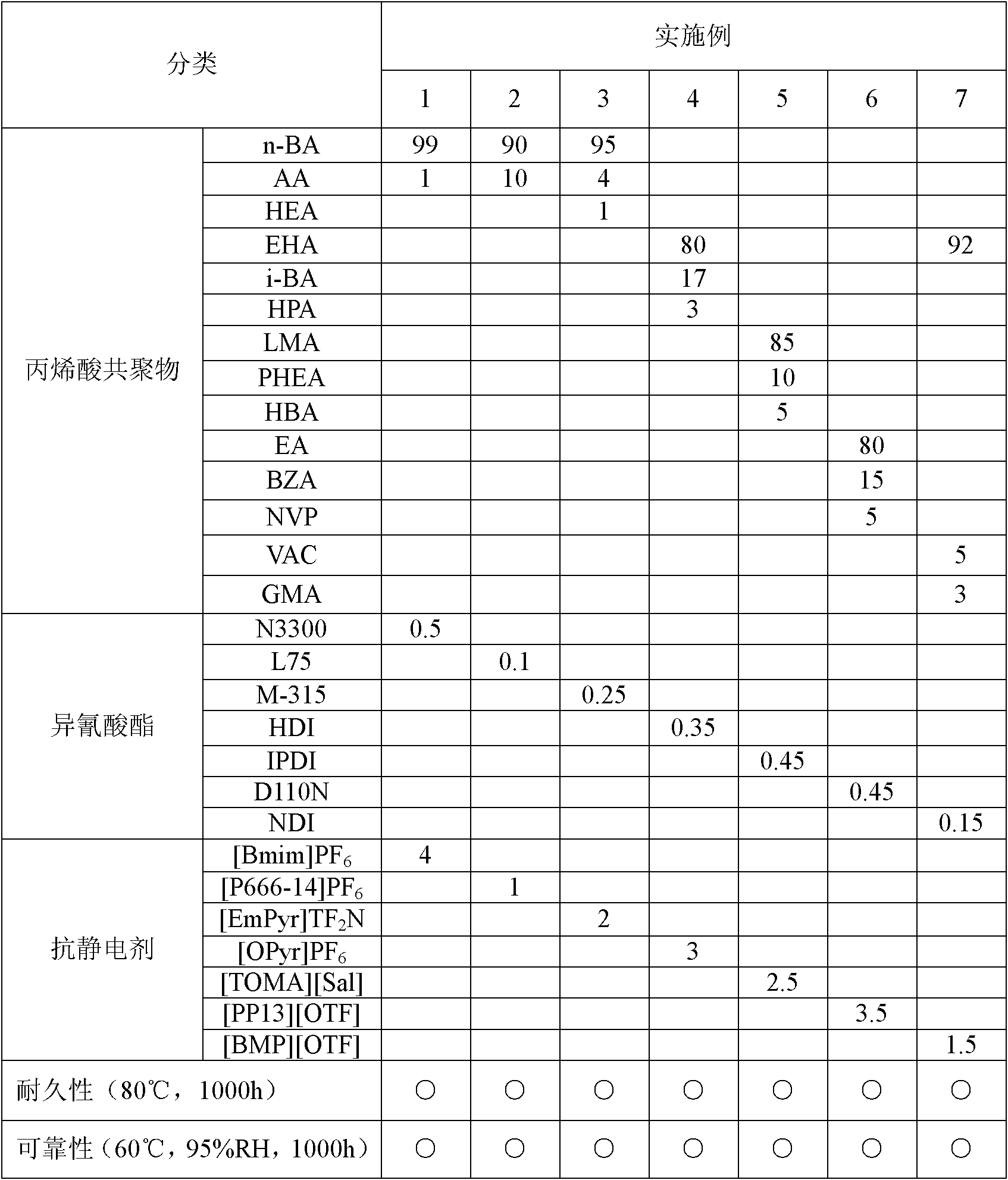

[0024] Weigh 99 parts of n-butyl acrylate (n-BA) and 1 part of acrylic acid (AA) in parts by weight, add them to a 1L four-necked flask equipped with a condenser and stirrer, and then add 100 parts of ethyl acetate The temperature in the bottle is maintained at 65° C. after deoxygenation by blowing nitrogen for 1 hour, adding 0.05 parts of initiator azobisisobutyronitrile (AIBN), reacting for 8 hours to obtain acrylic acid copolymer. 100 parts of the above acrylic copolymer, 0.5 parts of HDI trimer aliphatic polyisocyanate (N3300), 4 parts of 1-butyl-3-methylimidazole hexafluorophosphate ([Bmim]PF 6 ) Put it into a three-necked flask and mix evenly, adjust the mixture to a suitable viscosity with ethyl acetate, coat it on the release paper with a 40μm wire bar coater, and put it in an oven at 90°C to dry it.

[0025] The durability and reliability test results are shown in Table 1.

Embodiment 2

[0027] Weigh 90 parts of n-butyl acrylate (n-BA) and 10 parts of acrylic acid (AA) according to parts by weight, add them to a 1L four-necked flask equipped with a condenser and stirrer, and then add 100 parts of ethyl acetate The temperature in the bottle is maintained at 65° C. after deoxygenation by blowing nitrogen for 1 hour, adding 0.05 parts of initiator azobisisobutyronitrile (AIBN), reacting for 8 hours to obtain acrylic acid copolymer. 100 parts of the above acrylic copolymer, 0.1 part of trimethylolpropane toluene diisocyanate adduct (L75), 1 part of trihexyltetradecyl hexafluorophosphate ([P666-14]PF 6 ) Put it into a three-necked flask and mix evenly, adjust the mixture to a suitable viscosity with ethyl acetate, coat it on the release paper with a 40μm wire bar coater, and put it in an oven at 90°C to dry it.

[0028] The durability and reliability test results are shown in Table 1.

Embodiment 3

[0030] Weigh 95 parts of n-butyl acrylate (n-BA), 4 parts of acrylic acid (AA) and 1 part of 2-hydroxyethyl acrylate (HEA) according to parts by weight and add them to 1L equipped with condenser and stirrer. After the four-necked flask, add 100 parts of ethyl acetate. After deoxygenating with nitrogen for 1 hour, the temperature in the bottle is maintained at 65°C. Add 0.05 parts of initiator azobisisobutyronitrile (AIBN). After 8 hours of reaction, acrylic acid is obtained. Copolymer. Combine 100 parts of the above acrylic copolymer, 0.25 parts of tris(acryloxyethyl) isocyanurate (M-315), 2 parts of 1-ethyl-2-methylpyrazole bistrifluoromethanesulfonimide Salt ([EmPyr]TF 2 N) Put it into a three-necked flask and mix evenly, adjust the mixture to a suitable viscosity with ethyl acetate, coat it on the release paper with a 40μm wire bar coater, and put it in a 90°C oven to dry it.

[0031] The durability and reliability test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com