Hollow sunlight transmission fiber

A technology for transmitting optical fibers and sunlight, applied in the field of sunlight transmission optical fibers, can solve the problems of large output loss, low cost performance, unfavorable lighting, etc., and achieve the effect of reducing transmission loss, low transmission loss, and small output loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

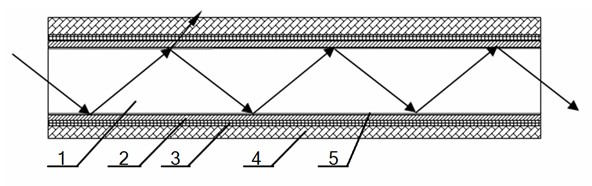

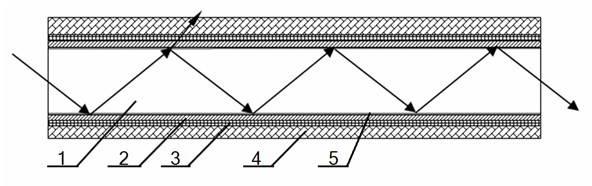

[0034] A hollow sunlight transmission optical fiber, which sequentially includes a hollow core layer 1, a reflective film 5, a quartz cladding 2, a polymer inner layer 3 and a polymer outer layer 4 from the inside to the outside, and the reflection film 5 has a reflectivity of sunlight 95%–99%, the refractive index of the reflective film 5 is between the hollow core layer 1 and the quartz cladding layer 2, the refractive index of the quartz cladding layer 2 is smaller than the refractive index of the polymer inner layer 3, and the refractive index of the polymer inner layer 3 Less than the refractive index of the polymer outer layer 4, and the thickness of the quartz cladding 2 is less than 300 microns; the quartz cladding 2 is a doped quartz cladding, and the doped substances in the quartz cladding 2 are germanium, fluorine, boron, Phosphorus or aluminum element, the polymer inner layer 3 is a fluorine-doped polymer coating layer, and its manufacturing material is fluorine-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com