Method for estimation of radiation heat loss of polysilicon CVD (chemical vapor deposition) reactor

A reactor, radiant heat technology, applied in silicon, instruments, special data processing applications, etc., can solve the problems of poor polysilicon production stability, high energy consumption, inaccurate estimation of radiant heat loss, etc., to achieve accurate radiant heat loss, Improved accuracy and low radiant heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

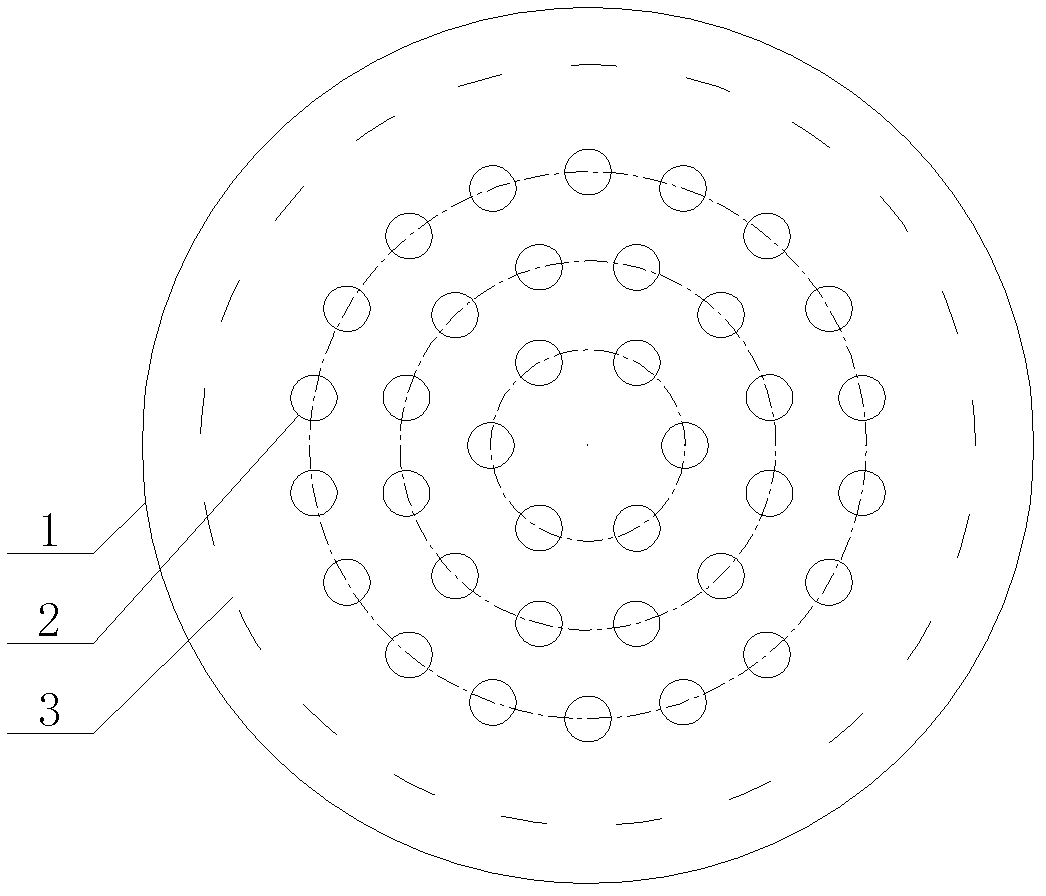

[0021] see figure 1 , taking 36 silicon rods (heating bodies) and a CVD reactor arranged symmetrically in three rings as an example, including the wall (1) of the CVD reactor and 36 silicon cores (2) arranged symmetrically in the form of three concentric rings , the position-adjustable heat shield (3), the optimum position of the heat shield can be estimated according to the calculation results of this method.

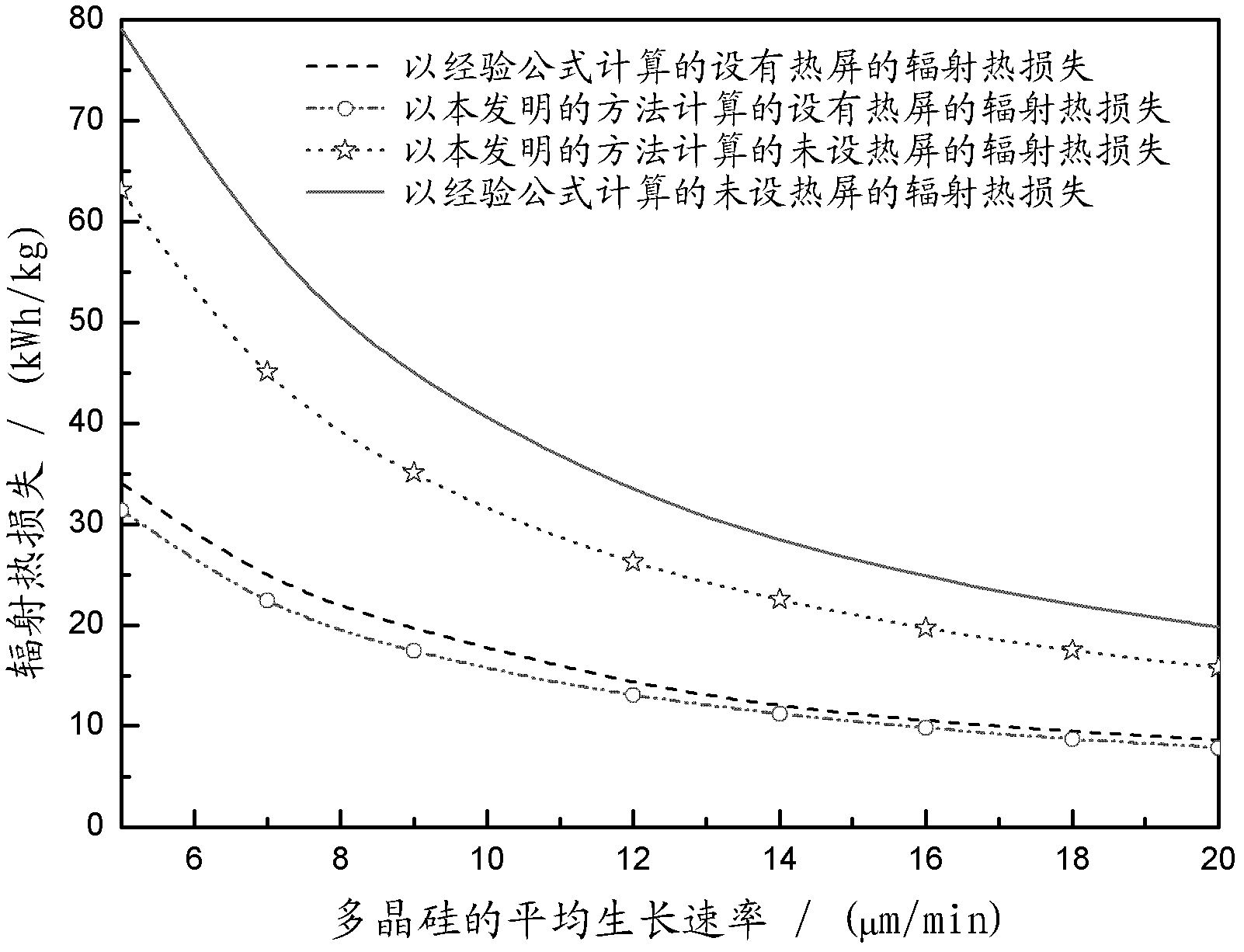

[0022] The method of the present invention is used to estimate the radiation heat loss of the CVD reactor.

[0023] In the first step, the radiant energy emitted by the wall 1 of the CVD reactor is regarded as composed of many energy beams, each energy beam has equal energy, and the energy emitted by the wall is one of the energy carried by the energy beam emitted by the wall. and;

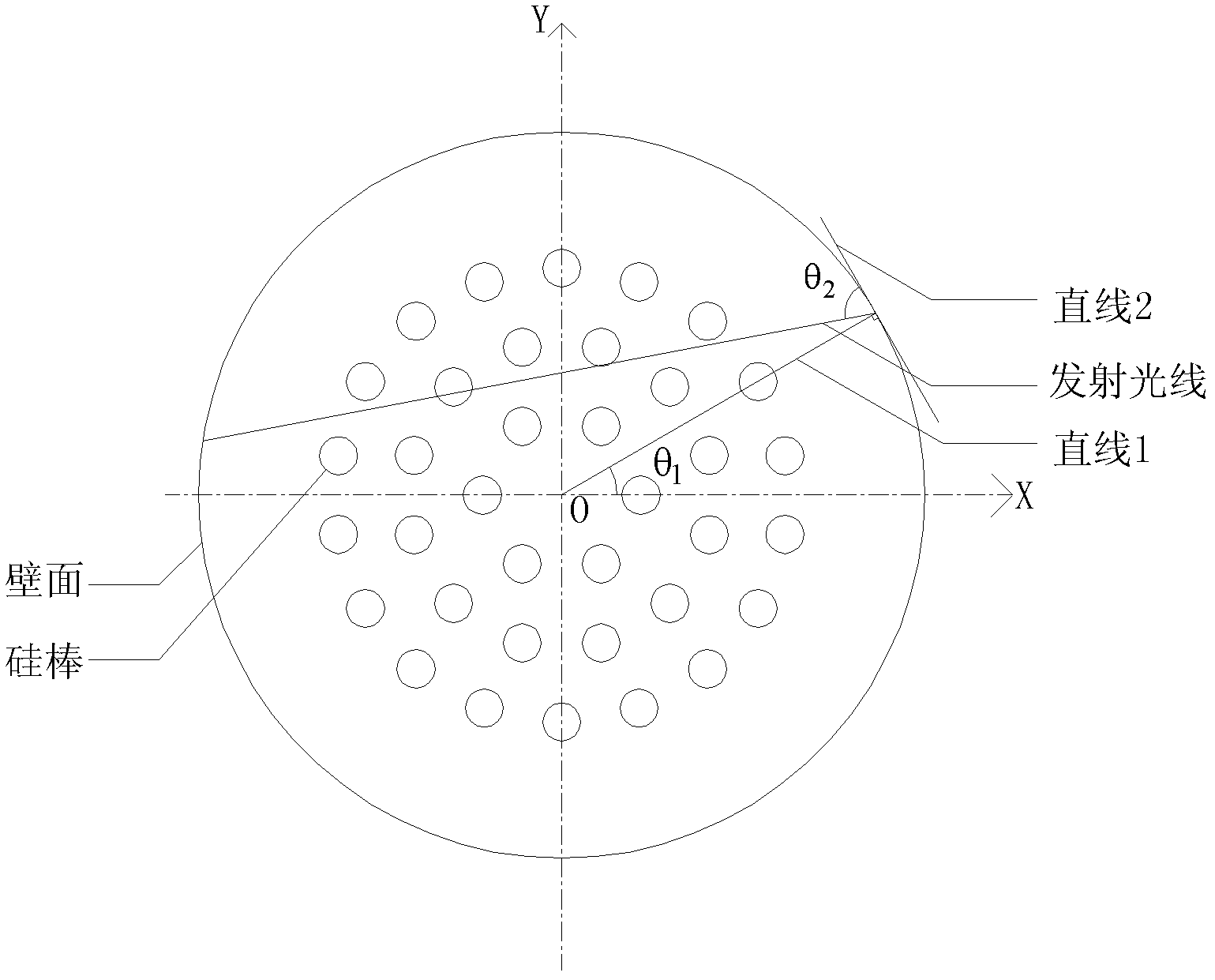

[0024] In the second step, in the coordinate system taking the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com