Method for improving output peak power of semiconductor laser unit

A peak power and laser technology, applied in the field of lasers, can solve the problems of Joule heat junction temperature rise, optical damage of crystal materials at the end face, device degradation, etc., and achieve the effect of increasing the output peak power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

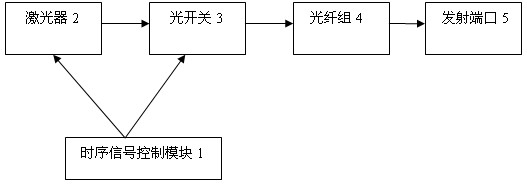

[0019] As shown in the drawings, the present invention includes a timing signal control module 1 , a laser 2 , an optical switch 3 , an optical fiber group 4 and a transmitting port 5 . The optical fiber group 4 is composed of optical fibers of different lengths. The timing signal control module 1 controls the optical switch 3 to turn on one of the optical fibers in the fiber group in turn, and at the same time close the rest of the optical fibers. The timing signal control module 1 simultaneously controls the pulse laser 2 to emit m optical pulses , these m optical pulses pass through the corresponding optical fibers in the optical fiber group 4 sequentially according to the time interval of the pulses, so that each optical pulse is superimposed at the emission port 5, thereby increasing the output peak power of the semiconductor laser, which can reach the original peak power m times.

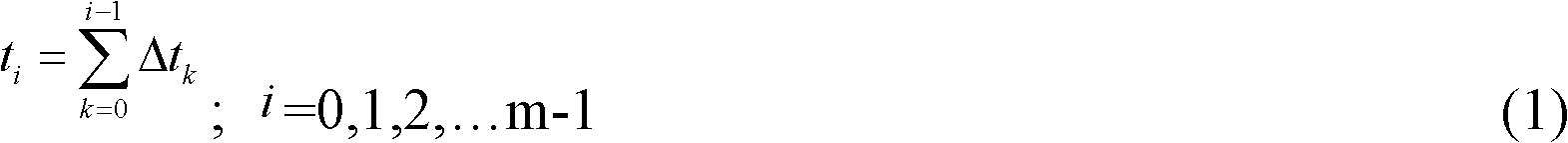

[0020] The present invention improves the principle of semiconductor laser output power: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com