Sterilization composition and use thereof

A composition and technology of Bacillus subtilis, applied in agricultural fungicides and its application fields, can solve problems such as water pollution, paddy field ecological environment, human health threats, etc., and achieve the effect of prolonging service life and alleviating resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

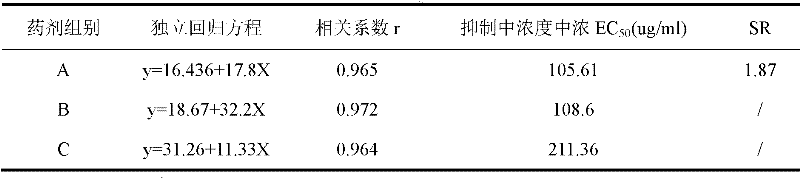

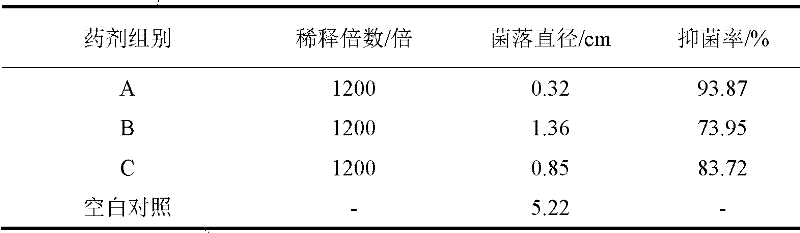

Examples

Embodiment 1

[0010] Prepare the following components by a certain weight percentage:

[0011] Polyoxin original drug 7.85g;

[0012] Bacillus subtilis 5g;

[0013] Wetting agent K12 (sodium lauryl sulfate) 4g;

[0014] Dispersant NNO (sodium methylene dinaphthalene sulfonate) 8g;

[0015] Light calcium carbonate supplemented to 100g.

[0016] Among them, 32% polyoxin original drug was provided by Wuhan Tianhui Bioengineering Co., Ltd.; 20 billion spores / gram Bacillus subtilis wettable powder was provided by Wuhan Konuo Biotechnology Co., Ltd. Put the polyoxin original drug and Bacillus subtilis in the mixer according to the above ratio, add a certain proportion of wetting agent K12 and dispersant NNO, fill it with light calcium carbonate to 100%, and mix all the materials in the mixer evenly , crushed twice by airflow to form 2.5% polyoxin · 10 billion Bacillus subtilis wettable powder.

Embodiment 2

[0018] Prepare the following components by a certain weight percentage:

[0019] Polyoxin original drug 50g;

[0020] Bacillus subtilis 35g;

[0021] Wetting agent K12 (sodium lauryl sulfate) 4g;

[0022] Dispersant NNO (sodium methylene dinaphthalene sulfonate) 8g;

[0023] Light calcium carbonate supplemented to 100g.

[0024] Among them, 32% polyoxin original drug was provided by Wuhan Tianhui Bioengineering Co., Ltd.; 20 billion spores / gram Bacillus subtilis wettable powder was provided by Wuhan Konuo Biotechnology Co., Ltd. Put the polyoxin original drug and Bacillus subtilis in the mixer according to the above ratio, add a certain proportion of wetting agent K12 and dispersant NNO, fill it with light calcium carbonate to 100%, and mix all the materials in the mixer evenly , crushed twice by airflow to form 2.5% polyoxin · 10 billion Bacillus subtilis wettable powder.

Embodiment 3

[0026] Prepare the following components by a certain weight percentage:

[0027] Polyoxin original drug 50g;

[0028] Bacillus subtilis 5g;

[0029] Wetting agent K12 (sodium lauryl sulfate) 4g;

[0030] Dispersant NNO (sodium methylene dinaphthalene sulfonate) 8g;

[0031] Light calcium carbonate supplemented to 100g.

[0032] Among them, 32% polyoxin original drug was provided by Wuhan Tianhui Bioengineering Co., Ltd.; 20 billion spores / gram Bacillus subtilis wettable powder was provided by Wuhan Konuo Biotechnology Co., Ltd. Put the polyoxin original drug and Bacillus subtilis in the mixer according to the above ratio, add a certain proportion of wetting agent K12 and dispersant NNO, fill it with light calcium carbonate to 100%, and mix all the materials in the mixer evenly , crushed twice by airflow to form 2.5% polyoxin · 10 billion Bacillus subtilis wettable powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com