Method for cladding wear-resisting layer on surface of runner hub of hydraulic turbine

A technology of surface coating and runner body, used in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficult strip surfacing process, difficult to guarantee the quality of the surfacing layer, and uneven thickness of the surfacing layer. , to achieve the effect of easy control, uniform thickness and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The base material of the runner body of the hydraulic turbine is ZG20SiMn carbon steel casting. The method of machining the stainless steel wear-resistant working layer on the spherical surface of the runner body is as follows:

[0073] (1) Carry out gold processing on the spherical surface of the runner body of the hydraulic turbine using a lathe to make the body size uniform and the surface smooth;

[0074] (2) Use a grinder to grind the spherical surface of the runner body, and then use acetone to remove surface oil;

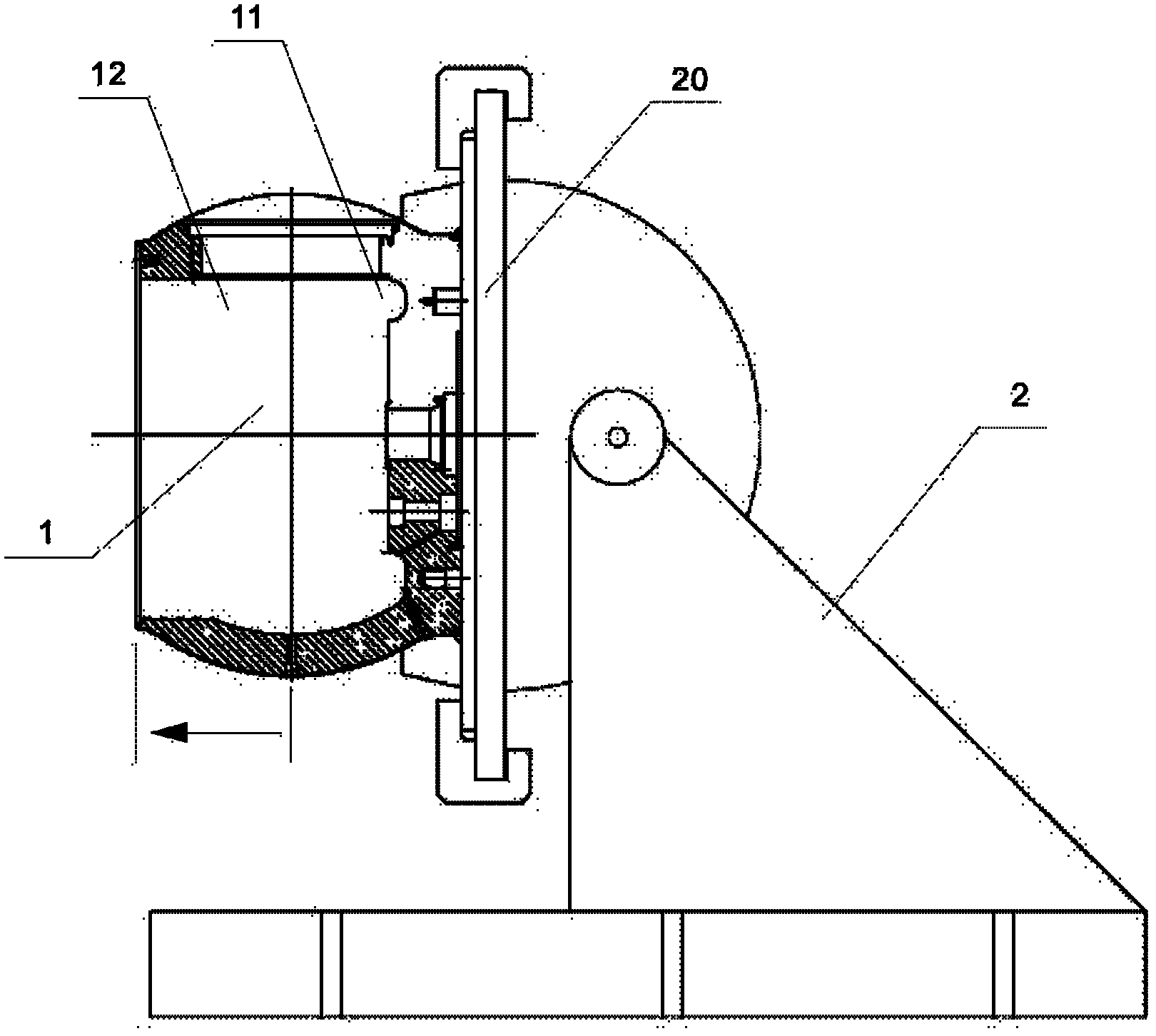

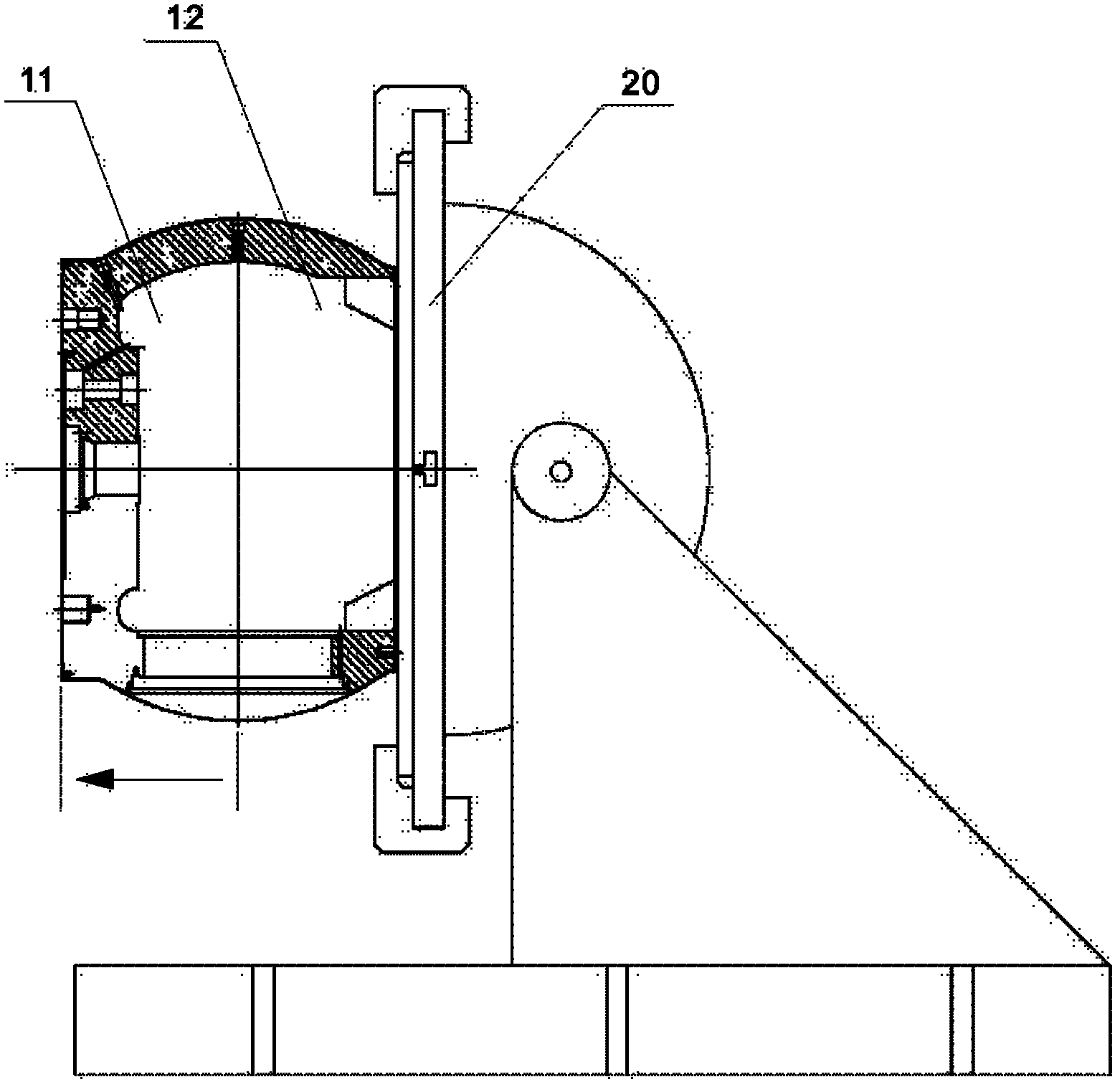

[0075] (3) Adjust the position of the runner body: if figure 1 As shown, the end of the main shaft side 11 of the runner body is fixed to the rotary table 20 of the welding positioner 2, and the turning angle of the rotary table 20 is adjusted so that the position of the surfacing area of the runner body is horizontal;

[0076] (4) Use a spray gun to flame-heat the weld bead area of the spherical surface of the runner body to remove water vapor. O...

Embodiment 2

[0094] The base material of the runner body of the hydraulic turbine is ZG20SiMn carbon steel casting. The method of machining the stainless steel wear-resistant working layer on the spherical surface of the runner body is as follows:

[0095] (1) Carry out gold processing on the spherical surface of the runner body of the hydraulic turbine using a lathe to make the body size uniform and the surface smooth;

[0096] (2) Use a grinder to grind the spherical surface of the runner body, and then use acetone to remove surface oil;

[0097] (3) Adjust the position of the runner body: if figure 1 As shown, the end of the main shaft side 11 of the runner body is fixed to the rotary table 20 of the welding positioner 2, and the turning angle of the rotary table 20 is adjusted so that the position of the surfacing area of the runner body is horizontal;

[0098] (4) Use a spray gun to flame-heat the weld bead area on the water discharge cone side 12 of the runner body to remove water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com