Fillet rolling technology for automobile air compressor crankshaft

An air compressor and rolling technology, which is applied in the fillet rolling process of the deep groove of the crankshaft journal of an automobile air compressor, can solve problems such as bending deformation and difficulty in correction, and achieve reduced bending deformation, improved product performance, Effect of improving fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

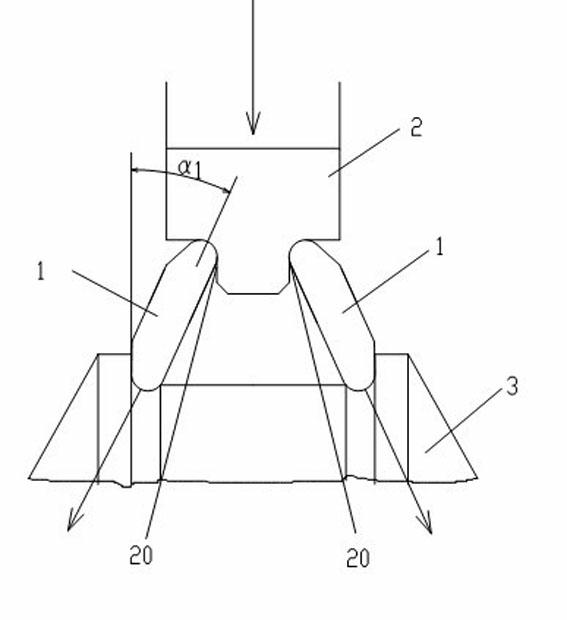

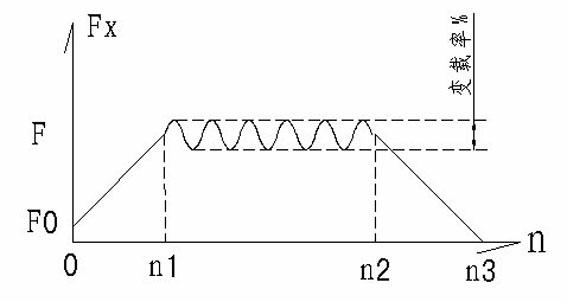

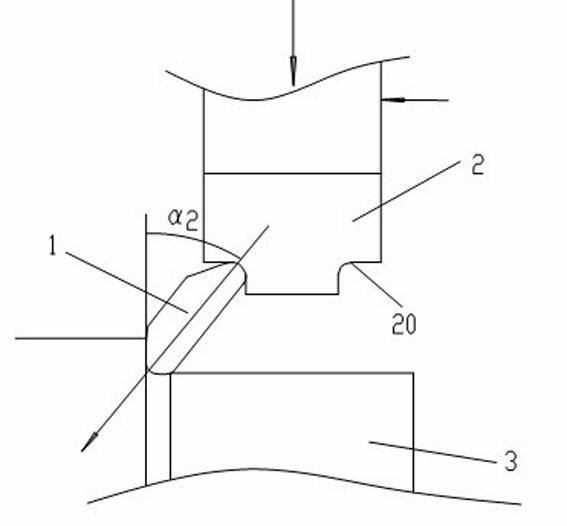

[0019] The crankshaft fillet rolling process of the automobile air compressor of the present invention is to increase the crankshaft fillet rolling process between the rough grinding connecting rod journal and the fine grinding connecting rod journal process, and the crankshaft fillet rolling process is added between the finishing car connecting rod journal and the side of the beginning At the same time, the arc sinking groove is turned out, and the connecting rod journal and the arc sinking groove are roughly ground after high-frequency quenching on the surface of the journal. After rough grinding, the bottom diameter of the arc sinking groove is smaller than the final diameter of the journal after fine grinding. Use a rolling wheel with a fillet radius smaller than the undercut groove for rolling.

[0020] The fillet rolling process includes the rolling of the deep groove fillet of the connecting rod journal and the rolling of the main journal of the output shaft end.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com