Sewage treatment method capable of sludge quantitative reduction

A sewage treatment method and reduction technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problems of high operating cost, large investment, immature technology, etc. , to improve the processing capacity, improve the surrounding environment, and achieve good sludge dewatering performance.

Inactive Publication Date: 2012-02-22

NANJING ZHONGSHI ENVIRONMENT TECH

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned technologies generally have disadvantages such as immature technology, high operating costs, and large investment.

The technology of ultrasonic treatment of sludge is currently in the stage of laboratory research in China, and has not been applied to engineering.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

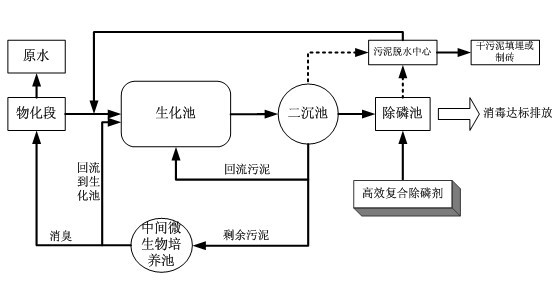

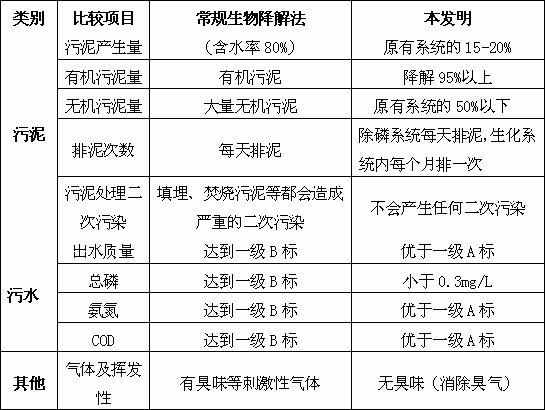

The invention discloses a sewage treatment method capable of sludge quantitative reduction. According to the invention, raw water enters into a physicochemical section at first, treated raw water is discharged into a biochemical tank for biochemical treatment, treated waste water enters into a secondary sedimentation tank, is settled and then is discharged after the waste water reaches the standard, one part of sludge is extracted from the secondary sedimentation tank and is allowed to reflow into the biochemical tank, the other part of sludge is sent to an intermediate microbial cultivation tank for culture of indigenous microorganism, one part of the cultivated sludge is sent to the front of the biochemical tank, and the other part of the cultivated sludge is sent to the physicochemical section for spray deodorization of the raw water in the physicochemical section; effluent of the secondary sedimentation tank enters into a dephosphorization tank for post chemical dephosphorization, and effluent after dephosphorization is discharged after reaching the standard; all sludge in the secondary sedimentation tank is discharged into a sludge dehydration center after a certain period, supernatant obtained after dehydration reflows to the front of the biochemical tank, and dried sludge is delivered out for landfilling or brickmaking. The method enables sludge quantitative reduction of a system to be realized in the treating process of sewage, an average annual sludge output of the system being 15 to 20% of that of an original system. Deodorization is carried out in the phase of pretreatment, thereby improving surrounding environments.

Description

[0001] technical field [0002] The invention relates to a sewage treatment method, in particular to a sewage treatment method with a sludge reduction function, which can reduce the amount of excess sludge in the sewage treatment process. Background technique [0003] Most of the sewage treatment in our country adopts the activated sludge method, which has the advantages of low capital investment and good treatment effect, but it has always had one of the biggest drawbacks, that is, a large amount of excess sludge will be generated during the operation process. Excess sludge usually contains a considerable amount of toxic and harmful substances and unstabilized organic matter. If not properly treated and disposed of, it will cause direct or potential pollution to the environment. In the traditional activated sludge method, every 1kgBOD degraded 5 (biochemical Oxygen Demand, five-day biochemical oxygen demand) will produce about 15-100 L of excess sludge, and the cost of tre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/14

Inventor 周浩男

Owner NANJING ZHONGSHI ENVIRONMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com