Solar module, solder strip, and method for connecting solder strip and solar battery

A technology for solar cells and solar modules, applied in the field of solar modules, can solve the problems of micro-cracks of solar cells, increasing fragmentation rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After any person of ordinary skill in the art understands the preferred embodiments of the present invention, they can be changed and modified by the technology inspired by the present invention. depart from the spirit and scope of the present invention.

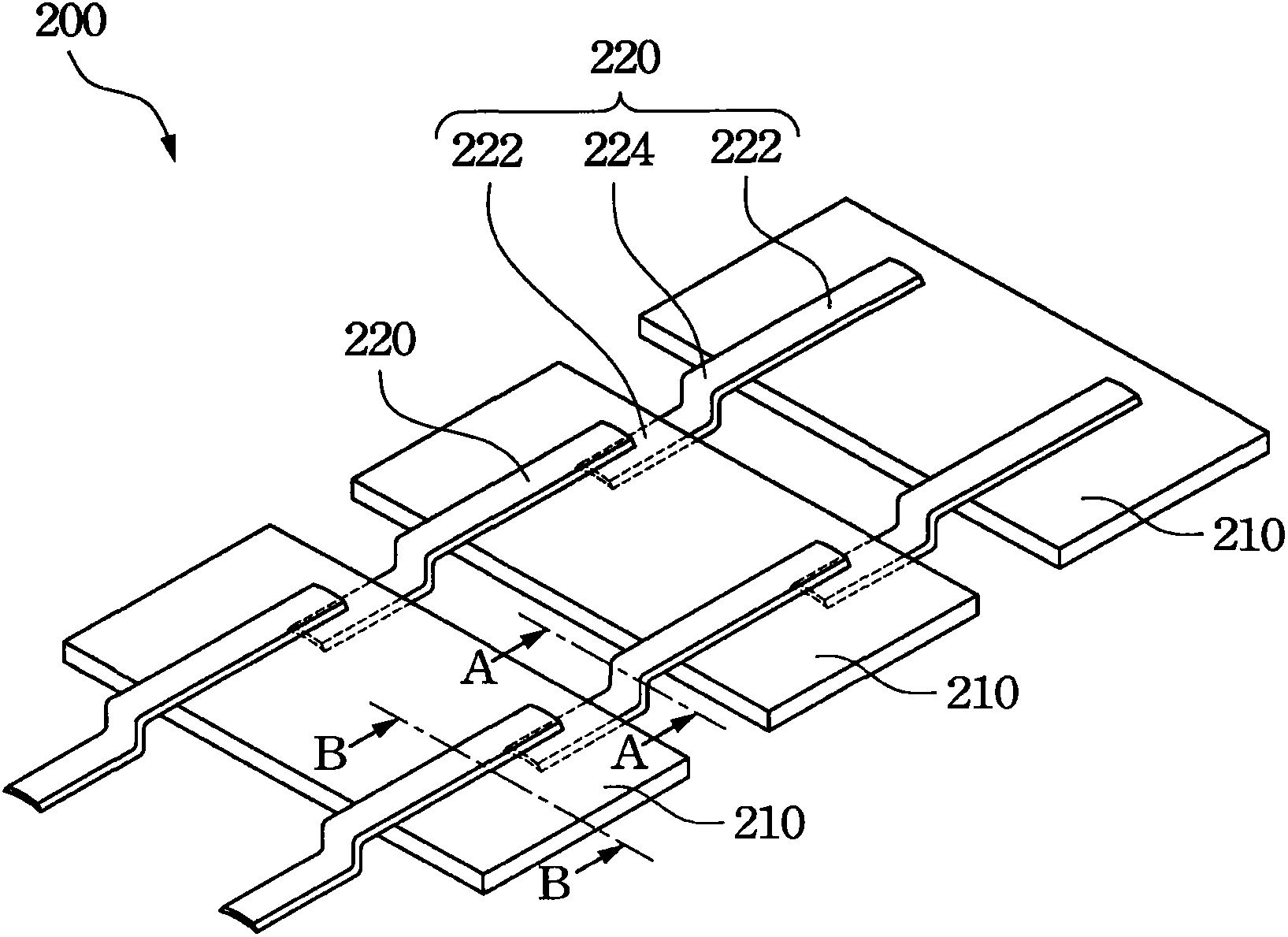

[0033] refer to figure 2 , which shows a perspective view of an embodiment of the solar module of the present invention before welding. The solar module 200 includes a plurality of solar cells (solar cells) 210 and a ribbon (ribbon) 220 for connecting the plurality of solar cells 210 . The solar cells can be configured in columns or rows, for example, and the solder ribbon 220 can be electrically connected to a junction box (not shown in the figure) arranged on the back panel to communicate with the solar cells 210 and the junction box, so as to control the solar cells. 210 and transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com