Pole piece for lithium ion battery, laminated lithium ion battery and preparation method of laminated lithium ion battery

A lithium-ion battery and pole piece technology, which is applied to non-aqueous electrolyte battery electrodes, secondary batteries, battery pack components, etc. The effect of reducing internal resistance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

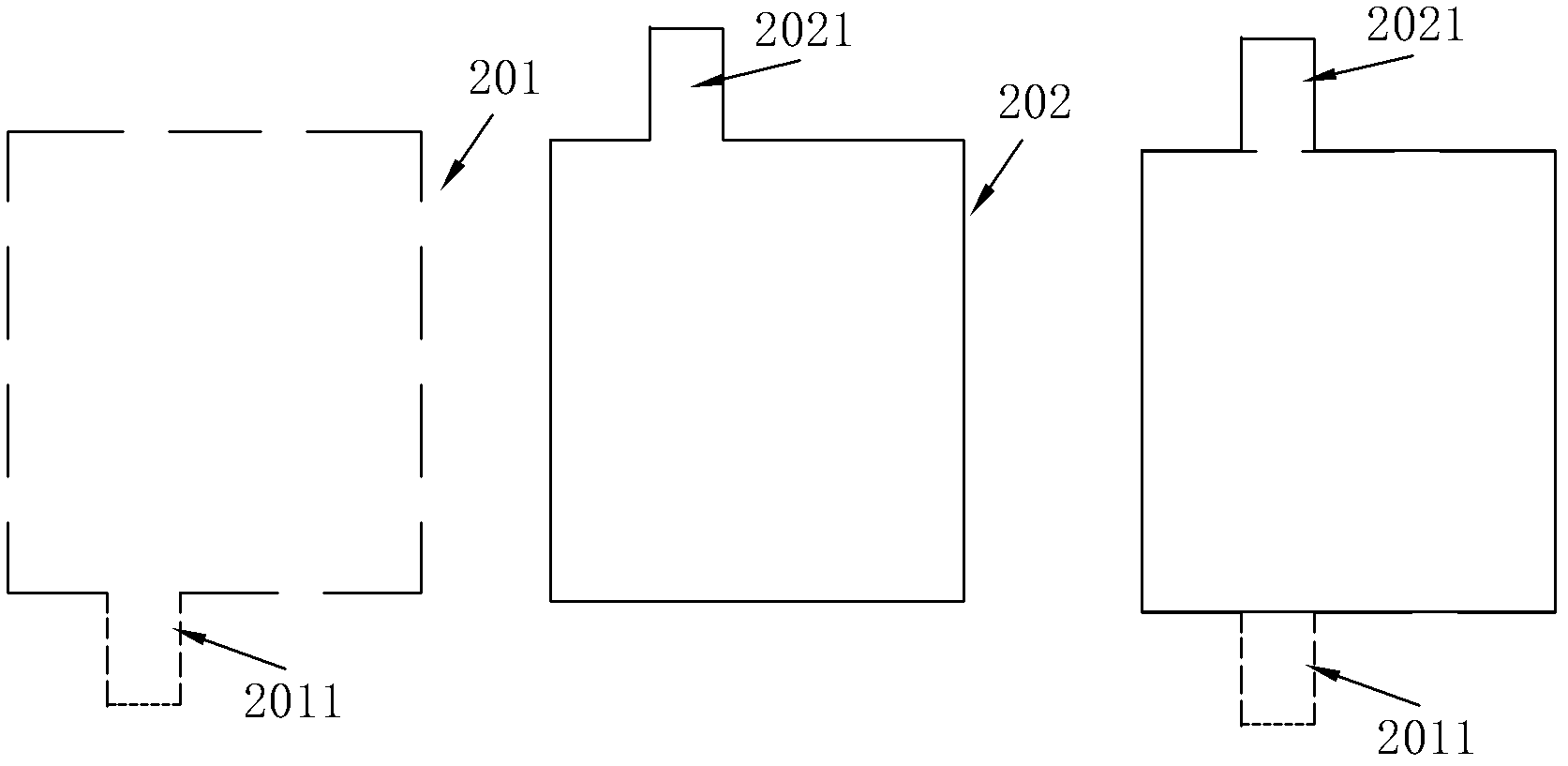

[0077] see image 3 As shown, this embodiment provides a schematic structural diagram of a novel pole piece for a lithium-ion battery.

[0078] see image 3 As shown, the pole piece of this embodiment is generally composed of a current collector foil and an electrode material layer coated on the surface of the current collector foil, and tab welding positions 3011 and 3021 extend and protrude from the foil. The difference between the pole piece of this embodiment and the conventional pole piece in the prior art mainly includes:

[0079] A pole piece of the present embodiment is made up of two sub-pole pieces with the same width: the first sub-pole piece 301 and the second sub-pole piece 302, the two sub-pole pieces 301, 302 are integrally connected, the two sub-pole pieces 301, Between 302 is a crease 303 that runs through the length direction of the pole piece. The sub-pole pieces 301 and 302 on both sides of the crease 303 can be bent along the crease 303 until the two sub...

Embodiment 2

[0125] Figure 8 It is a schematic diagram of the structure of the first pole piece provided in this embodiment.

[0126] Figure 9 for application Figure 8 A schematic diagram of the front structure of a stacked body of a laminated lithium-ion battery made of the positive electrode sheet and the negative electrode sheet of the structure shown.

[0127] see Figure 8 As shown, the first sub-pole piece 801 and the second sub-pole piece 802 on both sides of the crease in the pole piece provided by this embodiment have the same width and the same shape, which is the same as that in Embodiment 1. image 3 The differences in the structures shown mainly lie in that the position settings of the lug welding positions 8011 and 8012 on the two pole pieces are different. In this example:

[0128] The tab welding position 8011 of the first sub-pole piece 801 extends and protrudes on: the edge of the first width end of the pole piece; the tab welding position 8012 of the second sub-p...

Embodiment 3

[0135] see Figure 10 As shown, the difference between the pole piece provided in this embodiment and embodiment 1 is:

[0136] Although the sub-pole pieces 1002 , 1003 on both sides of the crease 1001 have the same width or even the same shape, the distances from the tab welding positions 10021 , 10022 of the two sub-pole pieces 1002 , 1003 to the crease 1001 are different.

[0137] application Figure 10 See Figure 11 shown.

[0138] exist Figure 11 Among them, four rows of tab welding positions are formed along the height direction of the laminated body as a whole: the tab welding positions 1101 and 1102 of the two rows of positive electrode sheets located side by side at one end of the laminated body are located at the other end of the laminated body The tab welding positions 1103 and 1104 of the two rows of positive electrode sheets arranged side by side. Figure 11 The A-A section structure see Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com