Box type transformer station

A box-type substation and substation equipment technology, applied in distribution substations, substation/switch layout details, substation/switchgear cooling/ventilation, etc., can solve the problems of complex wiring and large substation occupation, and achieve simple wiring , save construction cost, and occupy a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

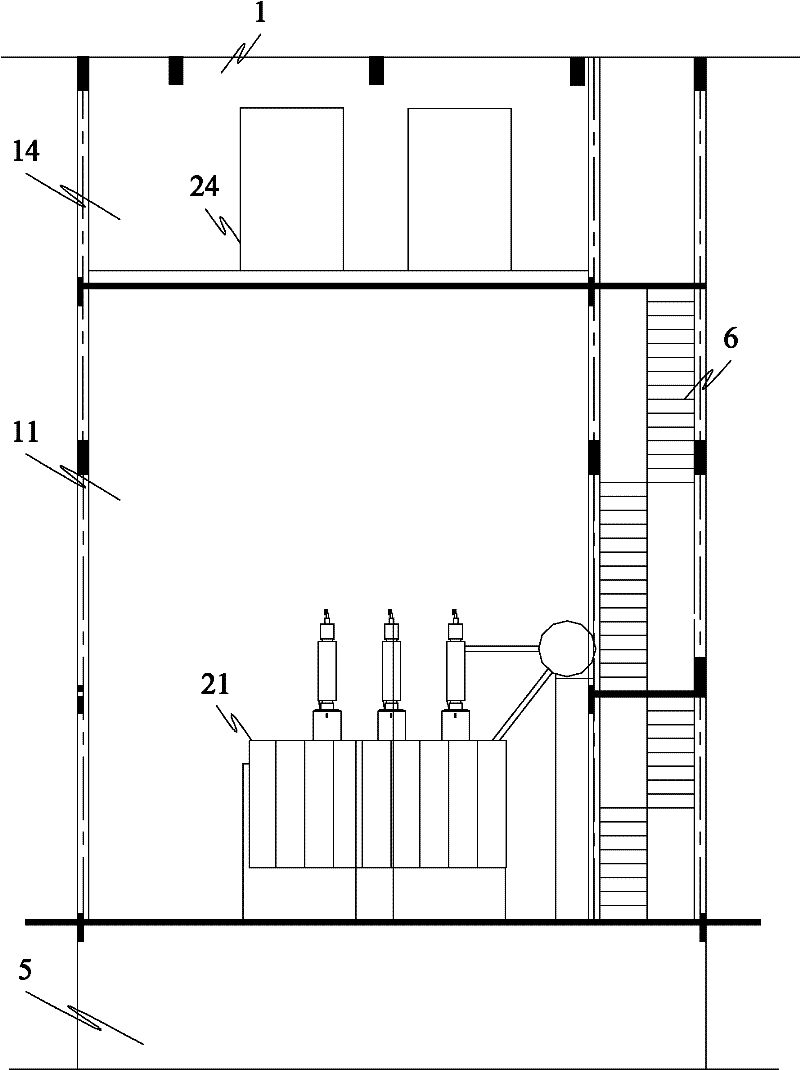

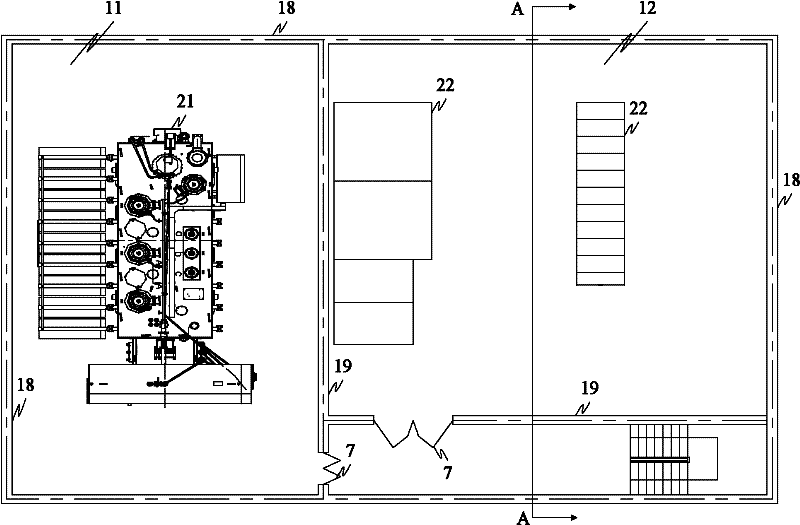

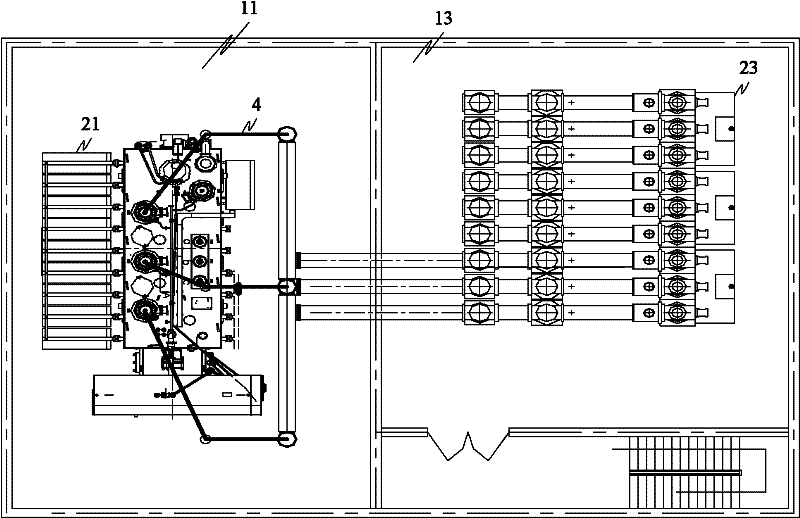

[0069] like Figure 1-5 As shown, the box-type substation of the present invention includes a three-layer box body 1, and the box body 1 is 14.5 meters long, 10.8 meters wide, and 15.5 meters high. Note: The low-voltage power distribution room does not refer to the low-voltage power distribution room, but refers to the medium-voltage 10KV lower than 220KV, which will not be repeated later) 12, of which the main transformer room 11 is 10 meters high and 10.8 meters wide, and the 10KV low Room 12 is 4 meters high and 10.8 meters wide. The overall length of main transformer room 11 and 10KV low distribution room 12 is 14.5 meters; the second floor of box body 1 is 220KV GIS room 13, which is set on 10KV low distribution room 12 , 7 meters high, 10.8 meters wide, and the length is consistent with the 10KV low distribution room 12. The 220KV GIS room is equipped with a 220KV high-voltage GIS; the third floor of the cabinet 1 is the main control room 14 and the capacitor room 15. O...

Embodiment 2

[0074] like Figure 6-10 As shown, the overall length of the box 1 is 14 meters (the length of the main transformer room 11 is 6 meters, and the length of the 220KV GIS room 13 is 8 meters), the width is 9 meters, and the height is 14.5 meters. The first floor is equipped with the main transformer room 11 and the 220KV GIS room. 13. The 10KV low distribution room 12 is located on the second floor. The 10KV low distribution room 12 is located on the 220KV GIS room 13. The main transformer room 11 is 10 meters high, the 220KV GIS room 13 is 6 meters high, and the 10KV low distribution room 12 is 4 meters high. The main control room 14 and capacitor room 15 are set on the third floor. The main control room 14 is set on the 10KV low distribution room 12, and the capacitor room 15 is set on the main transformer room 11. The capacitor room is 4.5m high, 9.0m wide, and 14.0m long. The overall structure and all the substation equipment (the electrical connection between the substation...

Embodiment 3

[0076] like Figure 11-15 As shown, as a modification of Embodiment 2, such as Figure 11-16 As shown, the main transformer 21 is composed of a transformer body 211 and a cooling group sheet 212. In order to better solve the heat dissipation problem of the main transformer 21, the transformer body 211 is placed in the main transformer room 11, and the cooling group sheet 212 is placed outside the main transformer room 11. , the length of the main change chamber is reduced relative to the second embodiment, so that the overall length of the casing 1 is reduced to 13 meters, as shown in the figure, wherein the length of the main change chamber 11 is 5 meters, and the length of the 220KV GIS chamber 13 is 8 meters, and other parts are consistent with the above-mentioned embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com