Clay crucible forming system

A clay crucible and molding machine technology, which is used in molding indenters, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of poor economic benefits, difficult to improve the rate of genuine products, difficult quality, etc., to reduce labor intensity and labor costs. , the effect of high genuine rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

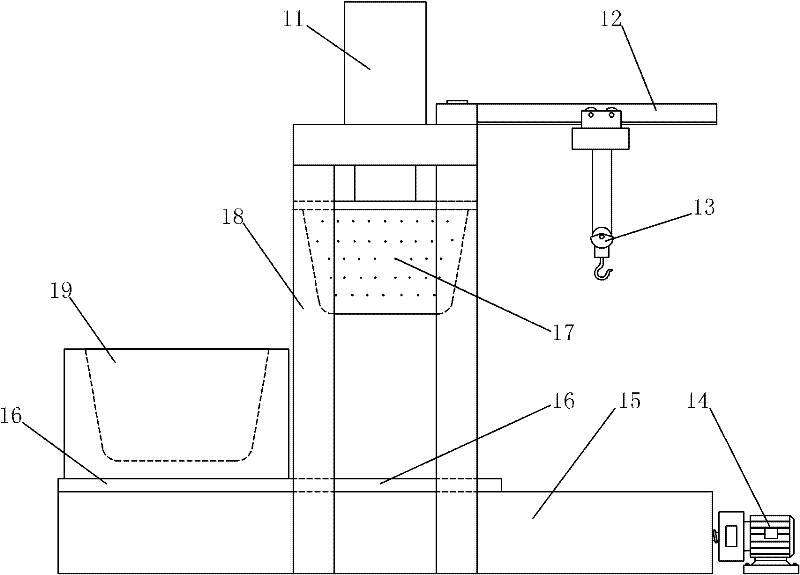

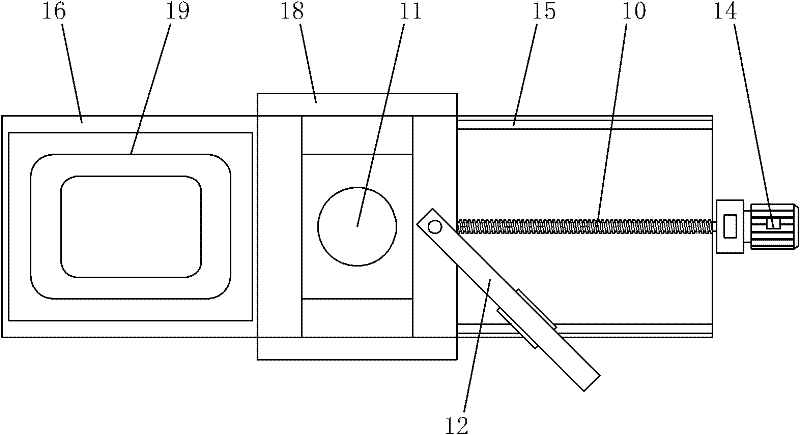

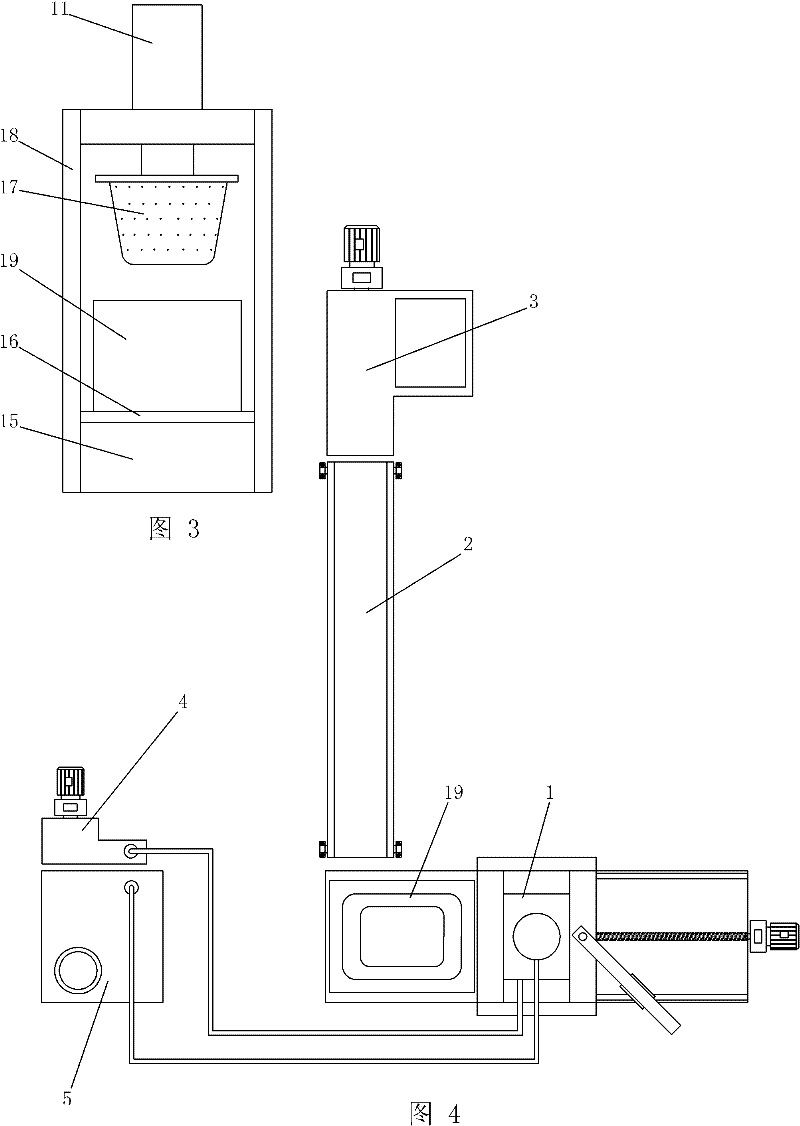

[0027] like figure 1 , figure 2 , image 3 A crucible molding machine shown is used for making and molding clay crucibles, and includes a frame on which an upper mold 17 is vertically slidably connected, and the upper mold 17 is fixed to the moving end of the oil cylinder 11 on the frame Connected so that it can move up and down and press molding under the drive of oil cylinder 11, the horizontal sliding connection on the frame is provided with supporting plate 16 that can do horizontal reciprocating movement under the drive of the driving mechanism, and supporting plate 16 is set on one side and upper mold 17 The matched lower mold 19, the other half of the supporting plate 16 is the bottom plate position for placing the crucible embryo body 6, wherein the lower mold 19 is a female mold, and the upper mold 17 is a male mold. On the wall of the upper mold 17 Evenly distributed with a plurality of air holes only for gas and water to pass through, these air holes communicate ...

Embodiment 2

[0038] like Figure 10A lower mold for a crucible molding machine shown includes a lower mold housing 191, a mold cavity 192 and a mold cavity wall 193, and a lower mold inner cavity 194 is formed between the lower mold housing 191 and the mold cavity wall 193. The mold cavity wall 193 is evenly distributed with a plurality of air holes 195 that only allow gas and water to pass through. In this way, during the pressing process, the gas and water extruded from the mud can be discharged into the inner cavity 194 of the lower mold through the air holes 195, thereby further improving the density and uniformity of the crucible body, and further avoiding perforation, cracking, etc. Quality issues while saving drying time. In order to prevent mud particles from entering the inner cavity of the upper mold or the surface of the crucible body is rough during pressing, the diameter of the pores on the cavity wall 193 of the lower mold is preferably 2-5 mm. The lower mold shell 191 is p...

Embodiment 3

[0041] like Figure 11 A lower mold for a crucible molding machine shown includes a lower mold housing 191, a mold cavity 192 and a mold cavity wall 193, and a lower mold inner cavity 194 is formed between the lower mold housing 191 and the mold cavity wall 193. A plurality of air holes 195 are evenly distributed on the cavity wall 193, and a filter cloth 197 covering the cavity wall 193 is provided in the cavity 192 of the lower mold. connected. Like this, in the pressing process, the gas and water from the mud material will be discharged in the lower mold cavity 194 through the filter cloth 197 and the air hole 195 due to extrusion and vacuum effect, so that the upper mold and the lower mold are separated from each other. The inside and outside of the crucible body removes the gas and moisture, thereby further improving the density and uniformity of the crucible body, further improving the quality of the product, and saving drying time; and during the demoulding process of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com