Bidirectional internal sealing structure of mechanical vibrator

A technology of rapping and internal sealing, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., to achieve the effects of prolonging service life, enhancing internal sealing ability, and increasing energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

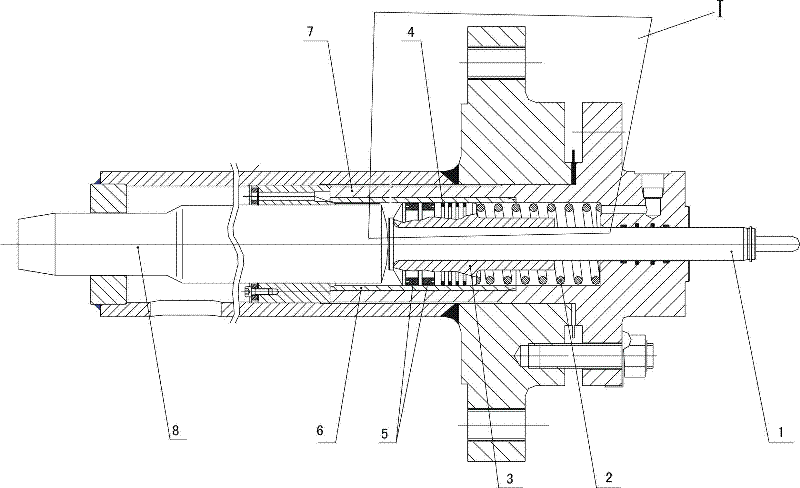

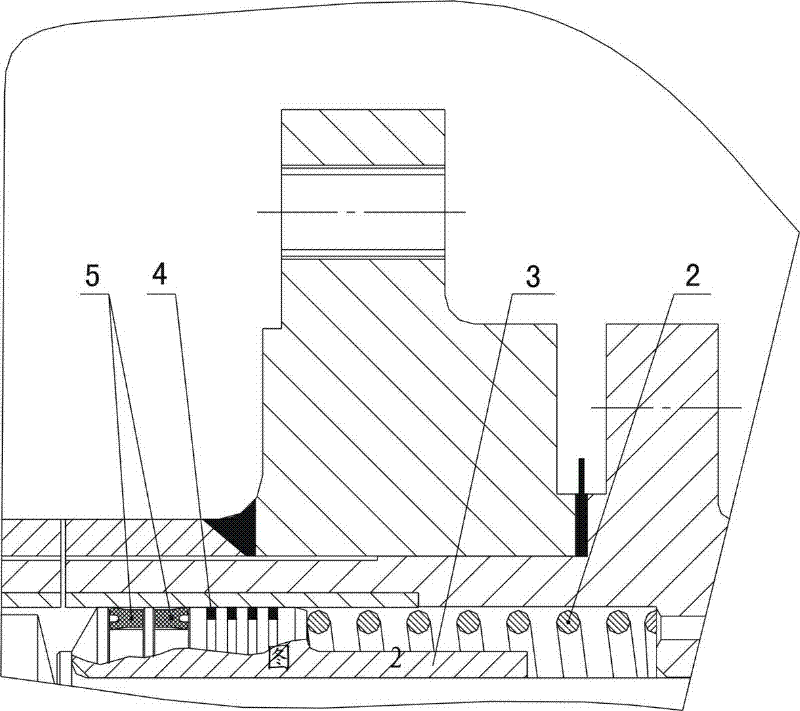

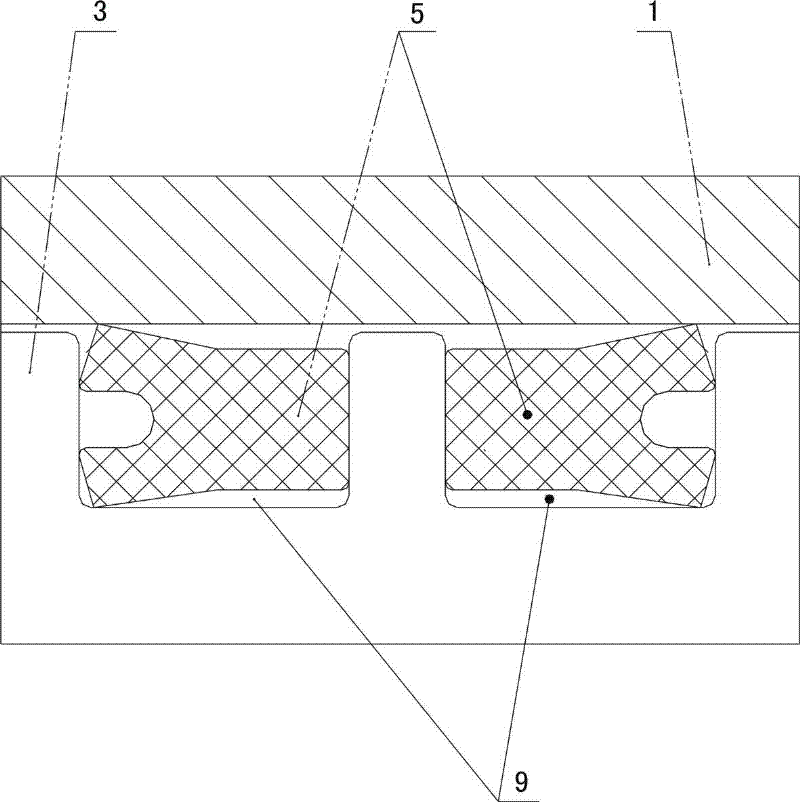

[0015] exist figure 1 , 2 Among them, the two-way internal sealing structure of the mechanical vibrator mainly includes a spring 2, a piston 3, a piston ring 4, and a two-way Y-shaped sealing ring 5. The spring 2 is installed at the bottom of the piston guide cylinder 7. With the help of the compressibility of the spring, When the piston guide cylinder 7 is installed, the spring 2 is allowed to have a certain compression range, which is very convenient during installation, much simpler and easier than the fixed installation; the piston is installed in the piston sleeve 6, and it is installed on the left side of the spring And connected closely with the spring. In the working state, due to the pre-tightening force of the spring 2, the inner surface of the piston is tightly pressed against the end surface of the piston rod 1, which acts as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com