Method for interconnecting electrodes of MEMS (micro electro mechanical system) device based on SOI (silicon-on-insulator)

A device and electrode technology, applied in the field of microelectronic machinery, can solve the problems of complex process technology, high technical difficulty, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

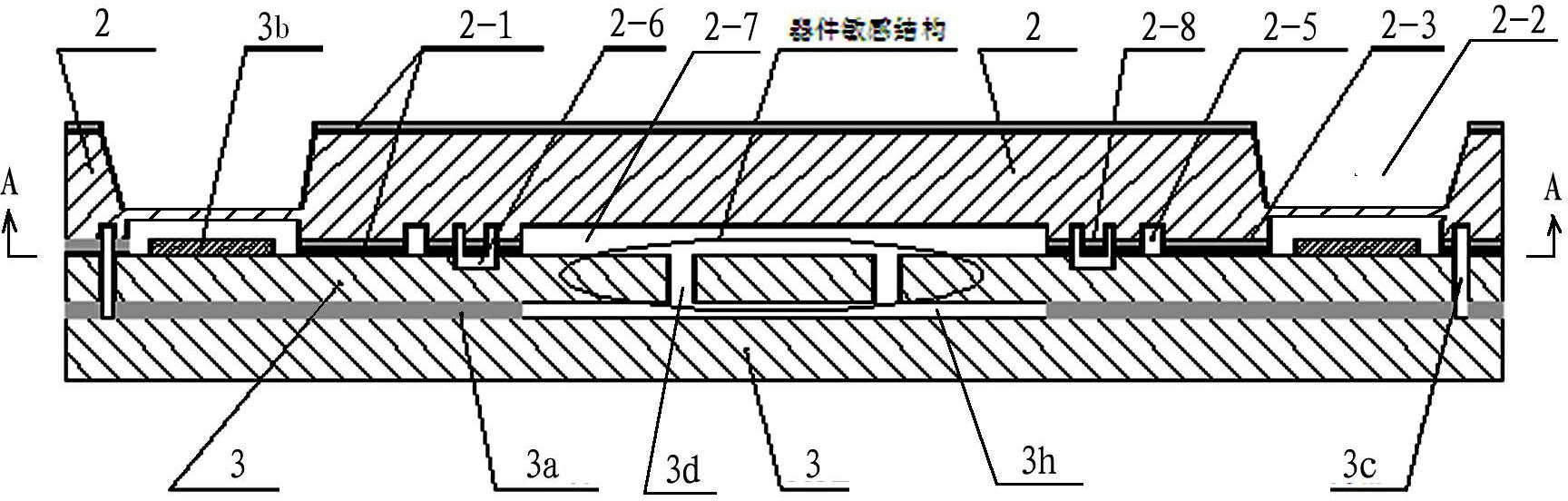

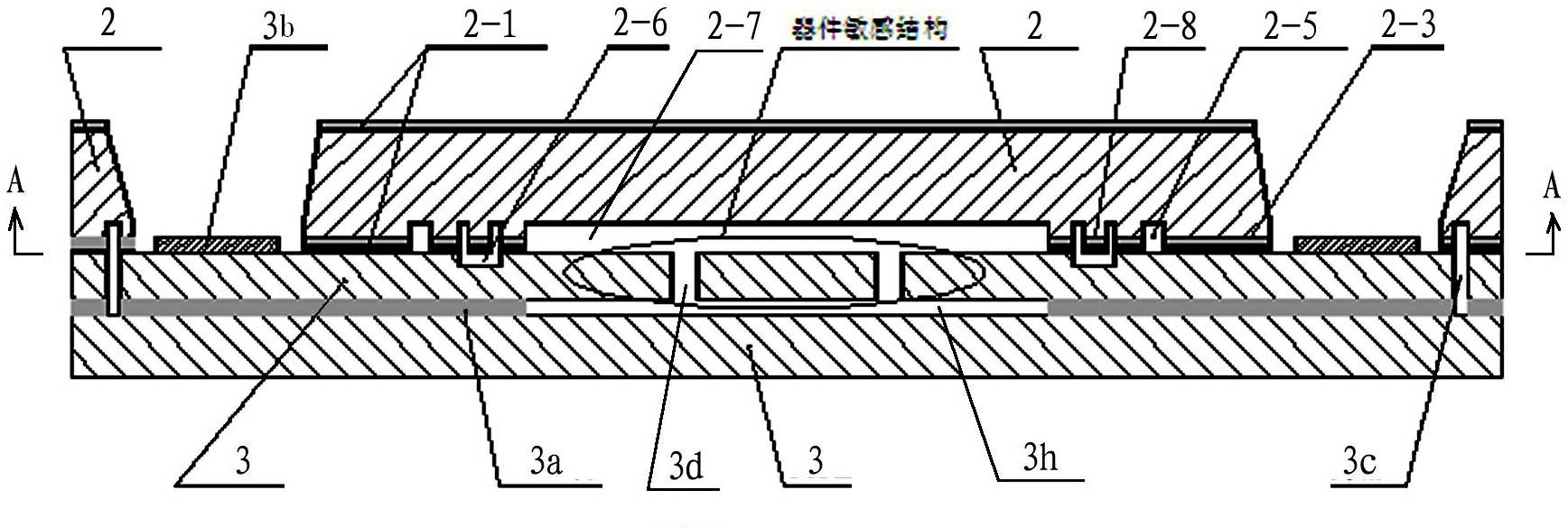

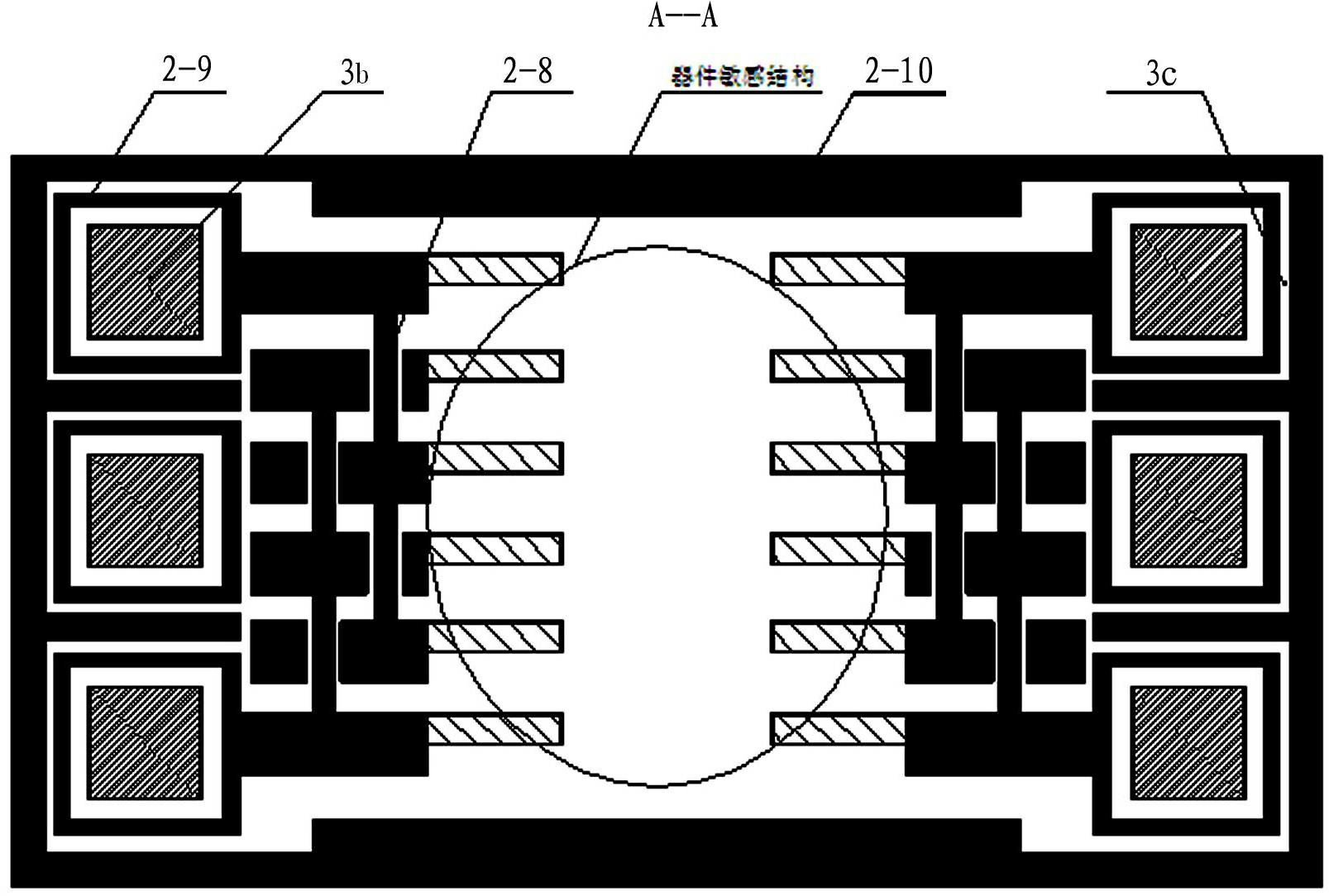

[0029] The method for interconnecting electrodes of SOI-based MEMS devices will be described below by taking a high-precision, high-performance capacitive MEMS device as an example.

[0030] (1) Fabrication of silicon cover plate

[0031] Figure 2-1 to Figure 2-4 in Figure 2 show the main process of silicon cover plate production, and the specific description is as follows:

[0032] (1) Growth of silicon dioxide: grow a layer of SiO on both sides of the cleaned double-sided polished silicon wafer 2 2 Thermal oxide layer 2-1. In the thermal oxidation furnace, the following parameters were used: 30 min O 2 (heating up) +10 minutes dry O 2 (920°C) +660 minutes wet O 2 (1100°C) +10 minutes dry O 2 (920°C) +N 2 (cooling), growing SiO 2 The thickness is more than 2 μm. The purpose of this oxide layer is to act as electrical isolation and as a masking layer for deep hole etching, such as Figure 2a shown.

[0033] (2) Making deep holes: use a photolithography process on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com