Preparation method and application of ethanol extract of laminarin

A technology of ethanol extraction and kelp polysaccharide, which is applied in the fields of application, tobacco, food science, etc., to achieve the effect of softening the taste, improving the quality of smoking, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

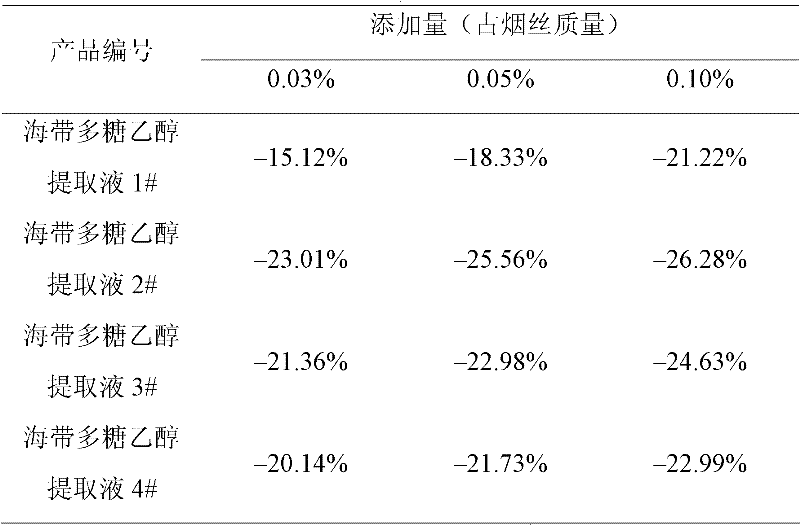

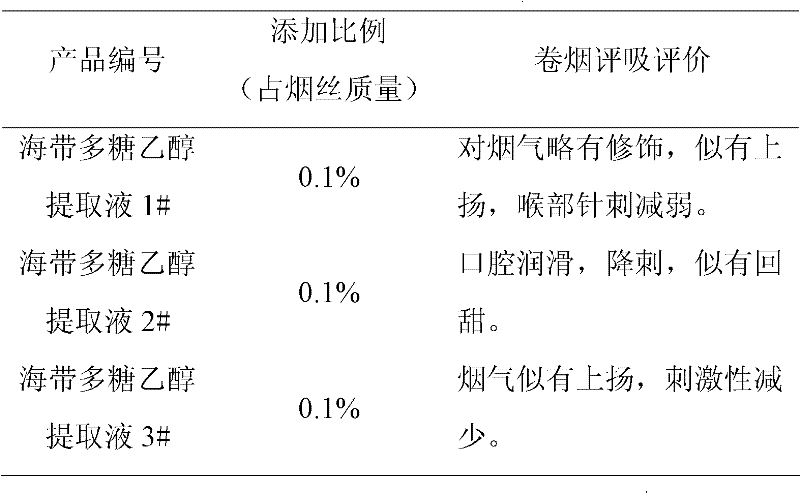

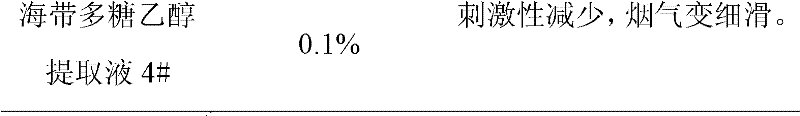

Examples

Embodiment 1

[0023] (1) After the kelp is crushed into 10-mesh kelp powder, 50 g is placed in a container, mixed evenly with 50% by weight ethanol solution at a weight ratio of 1:20, and extracted in an oil bath at 50° C. for 3 hours;

[0024] (2) Remove the residue by filtration, add 1% by weight of activated carbon to the extract, and process it at 50°C for 1 hour;

[0025] (3) filtering to remove activated carbon, concentrating to a dry matter content of 5% to 10%, and obtaining the laminarin ethanol extract. The obtained product number is laminarin ethanol extract 1#.

[0026] The IC50 of laminarin ethanol extract 1# in DPPH·free radical system is 0.48mg / mL.

Embodiment 2

[0028] (1) After the kelp is crushed into 40 mesh kelp powder, 50 g is taken and placed in a container, mixed evenly with 60% by weight ethanol solution at a weight ratio of 1:25, and extracted in an oil bath at 70° C. for 4 hours;

[0029] (2) Remove the residue by filtration, add 2% by weight of activated carbon to the extract, and process it at 55° C. for 1 hour;

[0030] (3) filtering to remove activated carbon, concentrating to a dry matter content of 5% to 10%, and obtaining the laminarin ethanol extract. The obtained product number is laminarin ethanol extract 2#.

[0031] The IC50 of laminarin ethanol extract 2# in DPPH·free radical system is 0.24mg / mL.

Embodiment 3

[0033] (1) After the kelp is crushed into 60-mesh kelp powder, 50 g is placed in a container, mixed evenly with 70% by weight ethanol solution at a weight ratio of 1:30, and extracted in an oil bath at 70° C. for 4 hours;

[0034] (2) Remove the residue by filtration, add 1% by weight of activated carbon to the extract, and process it at 60° C. for 1 hour;

[0035] (3) filtering to remove activated carbon, concentrating to a dry matter content of 5% to 10%, and obtaining the laminarin ethanol extract. The obtained product number is laminarin ethanol extract 3#.

[0036] The IC50 of laminarin ethanol extract 3# in DPPH·free radical system is 0.30mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com