Preparation method for aspartic protease inhibitor in enzymatic hydrolysis products of soybean protein isolate

A technology for protease inhibitor and soybean protein isolate, which is applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of unguaranteed safety and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

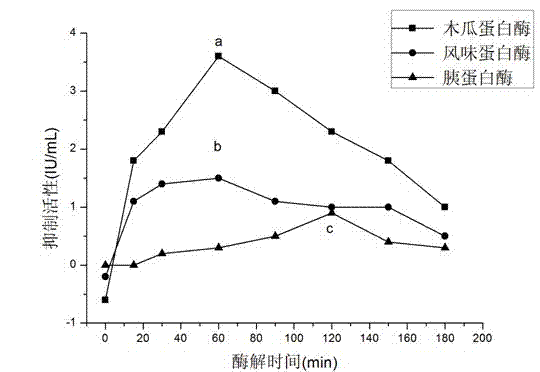

[0031] Prepare 300 mL of 5% soybean protein isolate solution, ① Take 100 mL of the solution and add 40,000 U of papain, adjust the pH to 6.5, put it in a water bath at 55°C for 200 min, and measure its effect on pepsin every 20 min. ②Take 100 mL of the solution and add 40000 U of flavor protease, adjust the pH to 3.0, put it in a water bath at 37°C for 200 min, and test its inhibitory activity on pepsin every 20 min; ③Take 100 40,000 U of trypsin was added to the solution, the pH was adjusted to 7.5, and it was placed in a water bath at 37°C for 200 min, and its inhibitory activity on pepsin was measured every 20 min. The results showed that papain enzymatically hydrolyzed soybean protein isolate for 60 min, and had the greatest inhibitory activity on pepsin, with an inhibitory activity of 3.6 IU / mL; flavor protease enzymatically hydrolyzed soybean protein isolate for 60 min, had the greatest inhibitory activity on pepsin, and the inhibitory activity was 3.6 IU / mL; 1.5 IU / mL; ...

Embodiment 2

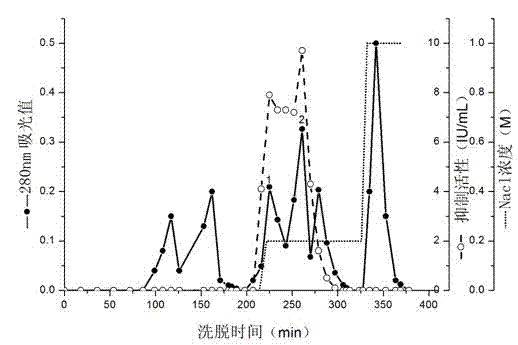

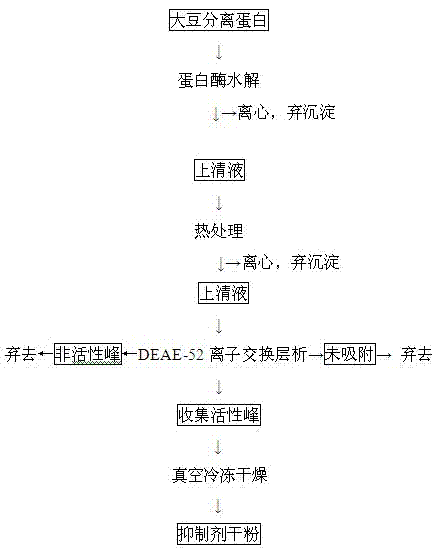

[0033]Prepare 100 mL of a 5% soybean protein isolate solution, add 40,000 U of papain, adjust the pH to 6.5, bathe in water at 55°C for 60 min, and centrifuge at 8,000 r / min and 4°C for 30 min to obtain the supernatant 98 mL, the supernatant was placed in a water bath at 70°C for 20 min, cooled to room temperature, and centrifuged at 8000 r / min at 4°C for 30 min to obtain 92 mL of supernatant, which had an inhibitory activity against pepsin of about 3.3 IU / mL, the supernatant was subjected to ion-exchange chromatography, and 20 mL of crude inhibitor was taken each time for DEAE-52 ion-exchange chromatography, which was 30 cm × 2.2 cm, and the equilibrium buffer was 10 mmol / L sodium phosphate buffer ( pH 6.8). Elution mode: After elution with equilibration buffer for 2 times the column volume, add 0.2, 0.4, 0.6, 0.8 mol / L NaCl phosphate buffer with different concentrations in sequence to equilibration buffer for stage elution, the flow rate is 1.5 mL / min, 280 nm wavelength U...

Embodiment 3

[0035] Prepare 150 mL of 5% soybean protein isolate solution, add 60,000 U of papain, adjust the pH to 6.5, bathe in water at 55°C for 60 min, and centrifuge at 8,000 r / min and 4°C for 30 min to obtain the supernatant 147 mL, the supernatant was placed in a water bath at 70 °C for 20 min, cooled to room temperature, and centrifuged at 8000 r / min at 4 °C for 30 min to obtain 138 mL of supernatant, which had an inhibitory activity against pepsin of about 3.4 IU / mL, the supernatant was subjected to ion-exchange chromatography, and 20 mL of crude inhibitor was taken each time for DEAE-52 ion-exchange chromatography, which was 30 cm × 2.2 cm, and the equilibrium buffer was 10 mmol / L sodium phosphate buffer ( pH 6.8). Elution mode: After elution with equilibration buffer for 2 times the column volume, add 0.2, 0.4, 0.6, 0.8 mol / L NaCl phosphate buffer with different concentrations in sequence to equilibration buffer for stage elution, the flow rate is 1.5 mL / min, 280 nm wavelengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com