Fuse salt jet impinging heat dump

A technology of jet impingement and molten salt, applied in the field of molten salt heat absorbers, can solve the problems of ablation thermal stress on the endothermic surface, uneven heat flow density, low heat transfer coefficient, etc. The effect of area and production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

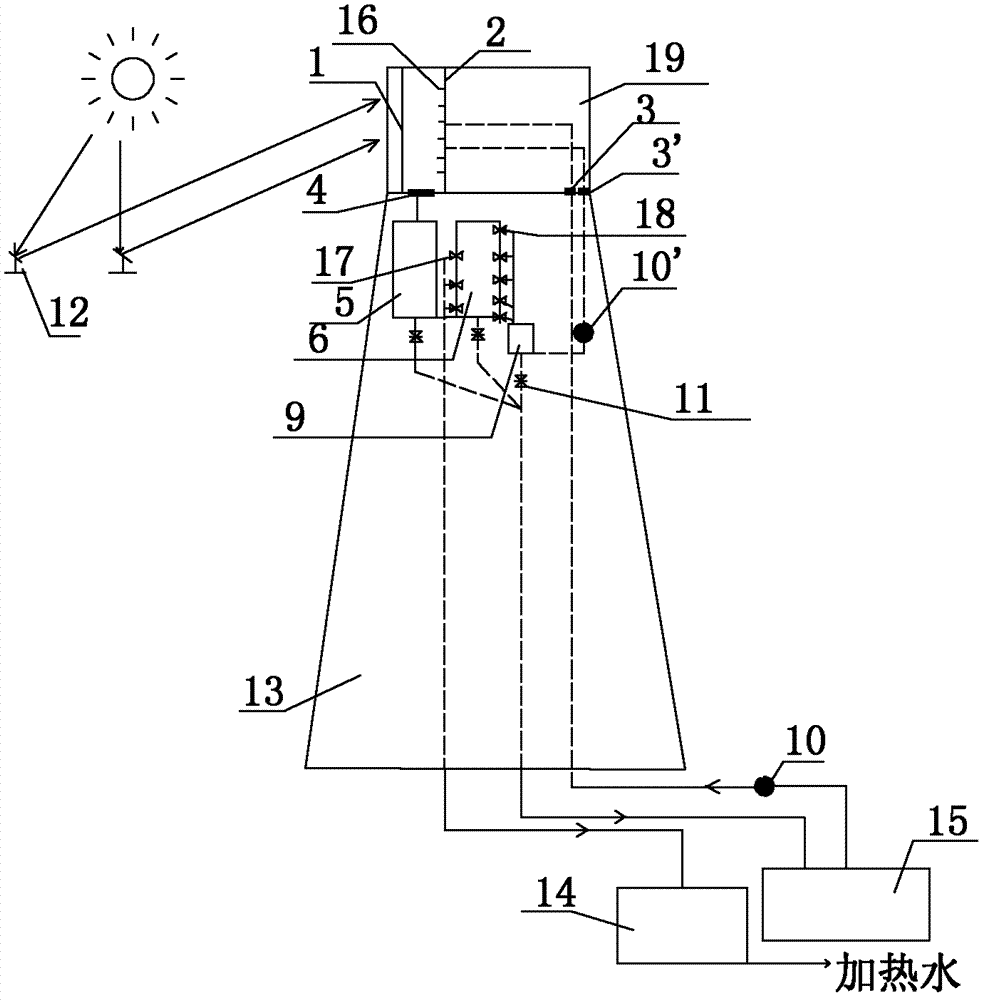

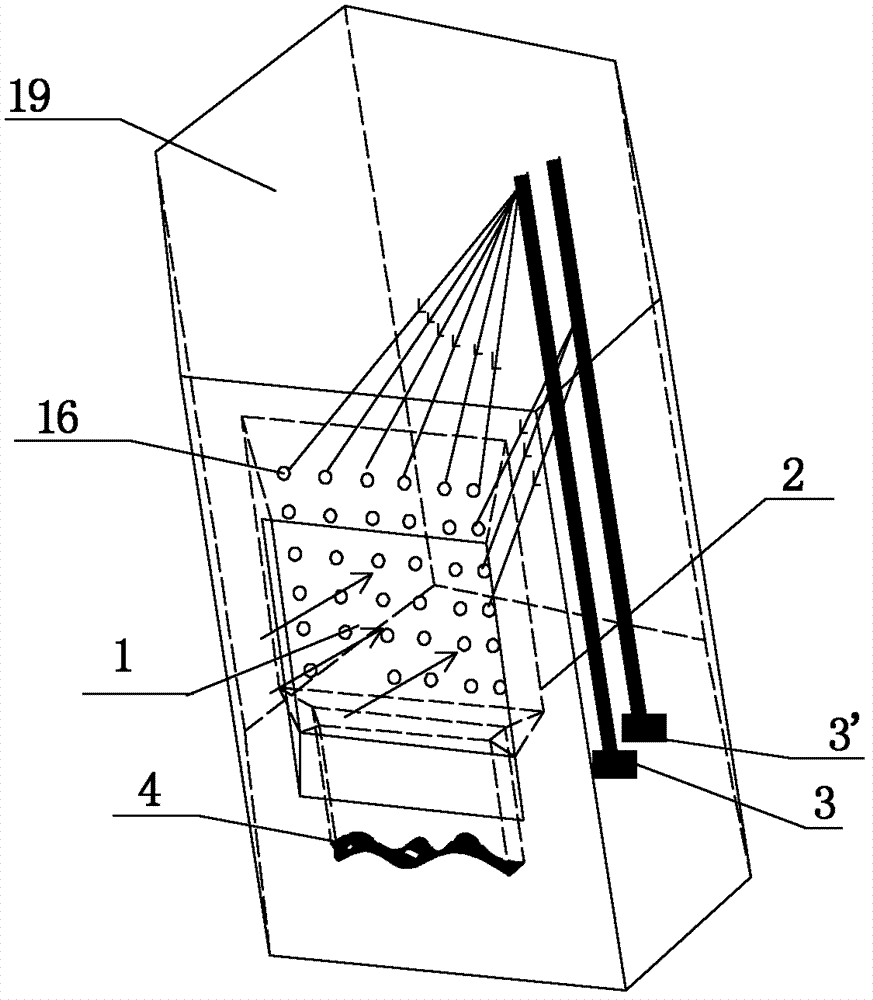

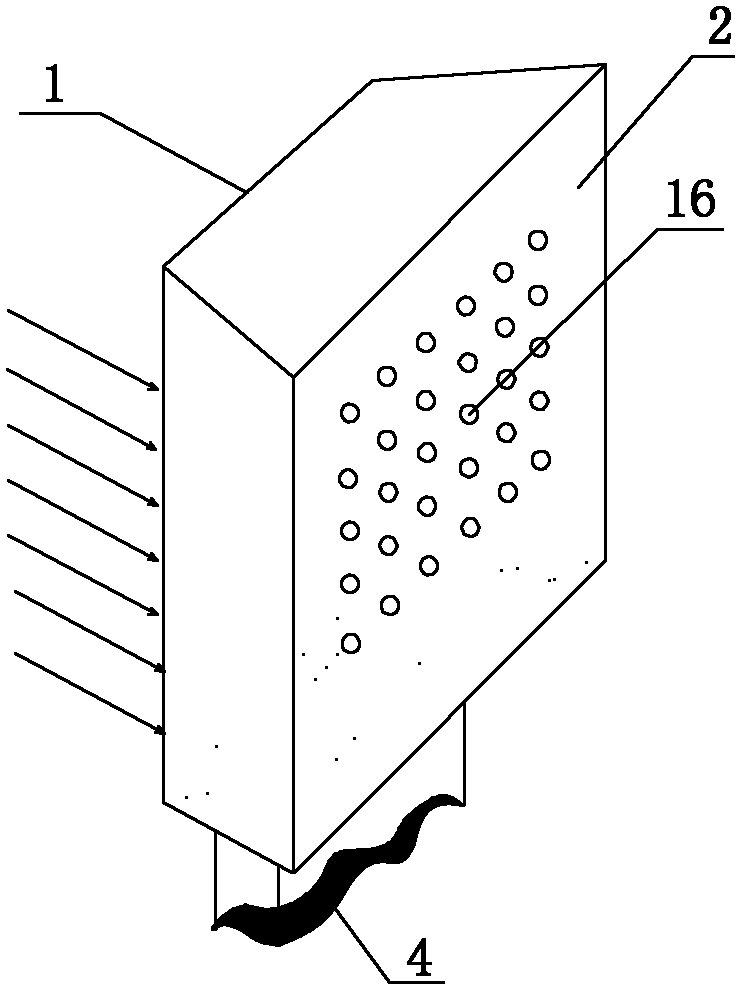

[0037] The molten salt jet impingement heat absorber 8 of the present invention has two specific embodiments: Example 1, a molten salt jet impingement chamber type heat absorber 19 ; Example two, a molten salt jet impingement cylindrical heat absorber 20 .

[0038] figure 1 It is a schematic diagram of the composition and structure of a solar power station equipped with a molten salt jet impingement cavity heat absorber of the present invention. Such as figure 1 As shown: the molten salt jet impingement cavity heat absorber 19 stands on the top of the sun tower 13, and can be perpendicular to the ground or have a certain angle with the ground. There are two inlets at the bottom of the molten salt jet impact cavity heat absorber 19, the inlet of the first inlet 3 is connected to the cold tank 15 through the pump 10 through the pipeline, and the outlet of the first inlet 3 is connected to the cold tank 15 through the pipeline. The inlet of the nozzle 16 on the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com